68 | P a g e

Servicing the expansion vessel.

The expansion vessel charge should be checked on every service and set as per table 9.2.a of the Manufacturer’s

Instructions.

Expansion vessels themselves may need to be fully serviced if the vessel is losing pressure or has water coming out

of the Schrader valve. Over time expansion vessels can gather up to half a litre of condensation water in the air

chamber from repeated re-pressurisations and that water that can sit in the charge hose.

The water can easily be removed to avoid unnecessary replacements and return the vessel to factory condition thus

improving performance.

To correctly service the ATAG expansion vessel, follow the below instructions:

1. Remove the system pressure via a drain point (not PRV). Remove the diverter valve actuator on a combi before

doing this to ensure boiler is fully drained.

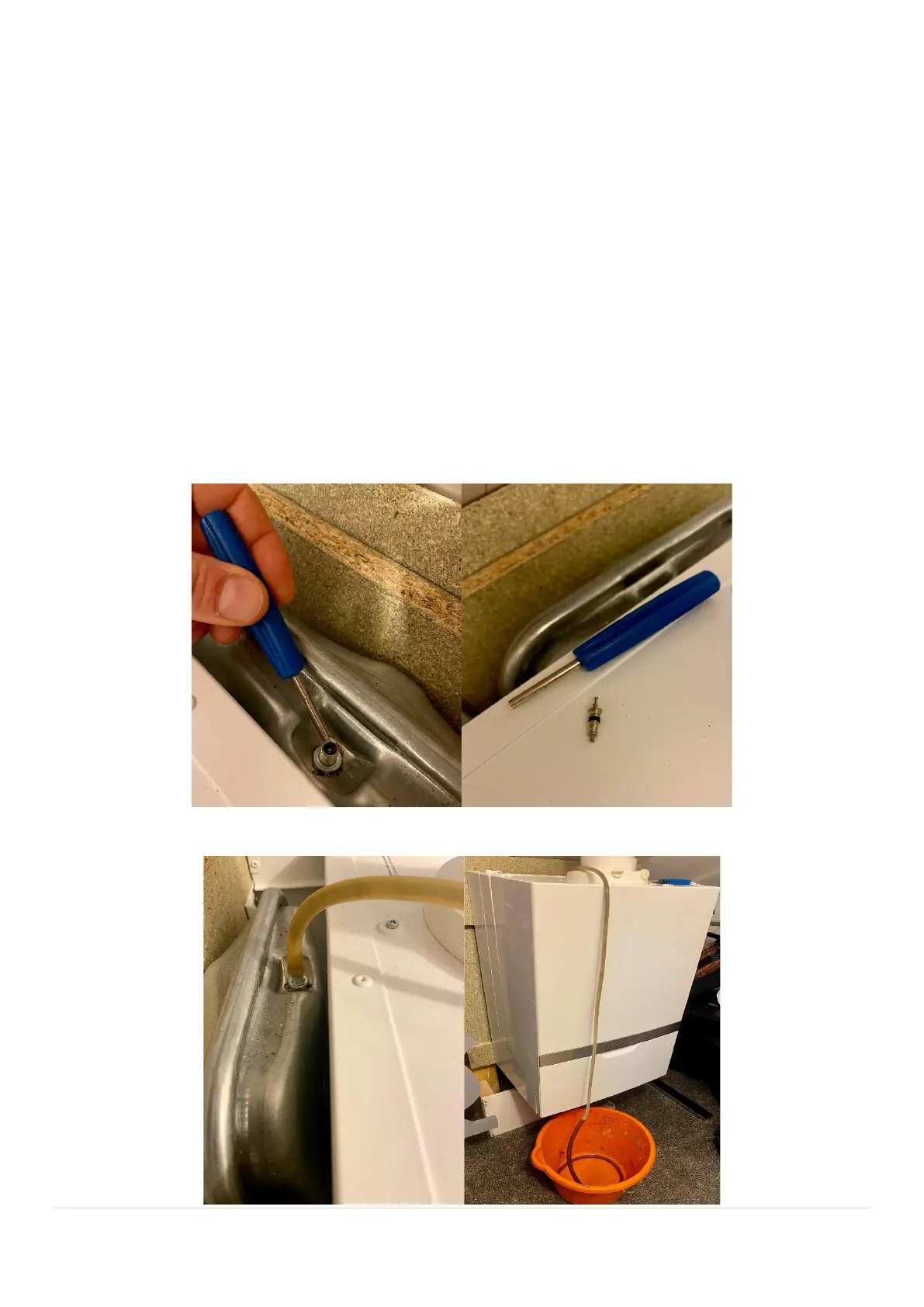

2. Depressurise expansion vessel and remove Schrader core.

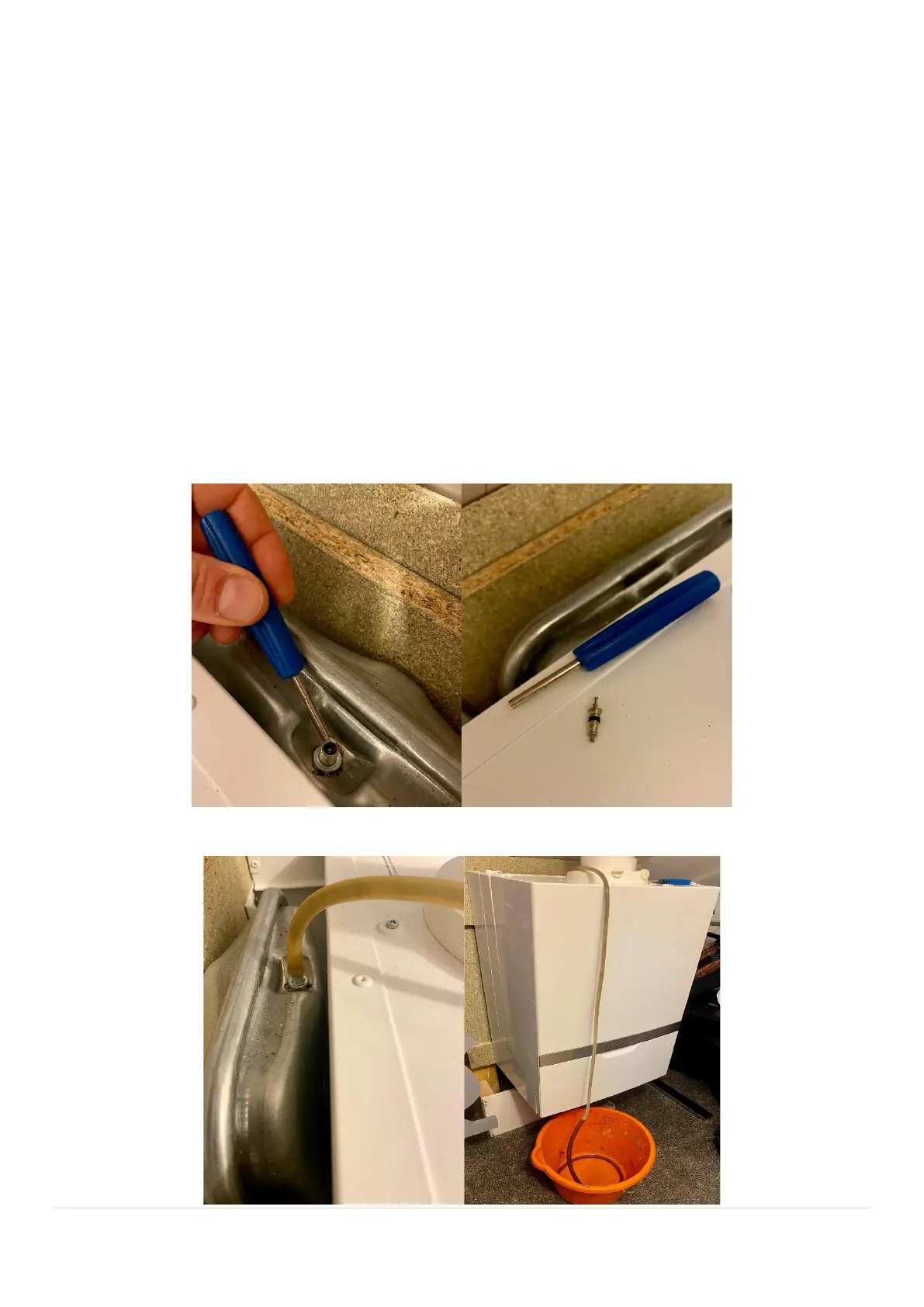

3. Attach a tube to the Schrader valve to a bucket.

Loading...

Loading...