43

Motors with backstop

Motors with built-in backstop must be operated at a minimum rpm higher

than the value specified on the rating plate – e.g. FXM 850 min

–1

– to

prevent excessively high temperatures.

Heat input through the driven machine

It must be ensured that no quantities of heat greater than the maximum

heating values specified in table are conveyed from a mounted machine to

the interface with the motor (e.g. shaft and motor flange). This way it is

guaranteed that no point of the motor exceeds the temperature class.

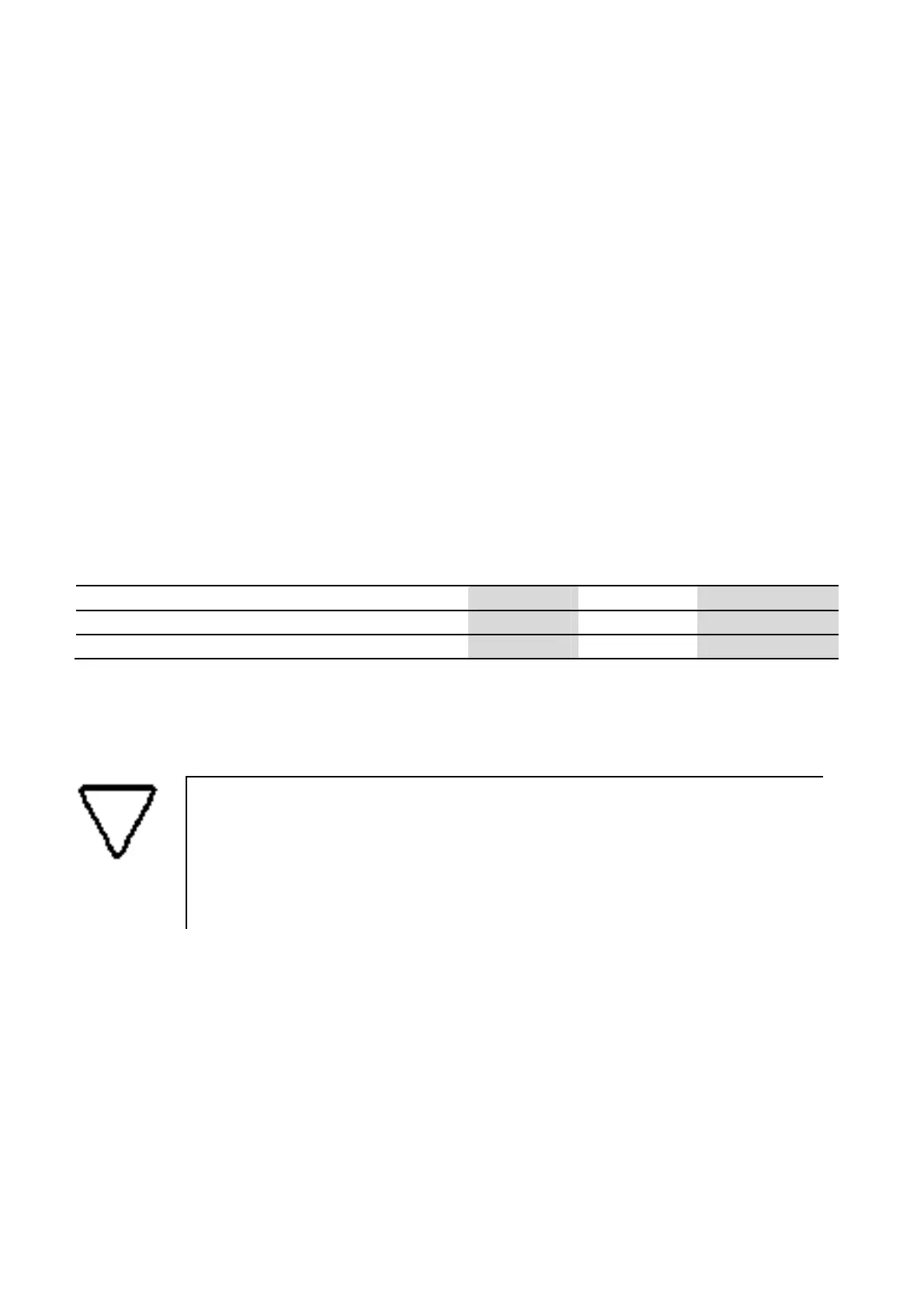

Table 9:

Permissible surface heating at an ambient temperature of 40°C:

Temperature class

T6 = 85°C T5 = 100°C T4 =135°C

Permissible heating on the shaft 30K 45K 65K

Permissible heating on the flange 30K 45K 65K

Start-up

Please note!

Before mounting or start-up the insulation resistance is to be

measured by qualified technicians. The resistance must be

greater than 1 MΩ. A critical value is reached at 0.5 MΩ. If this

value is not reached, the motors must be dried.

The best way to do it is in an oven at temperatures up to 100 °C. To

eliminate any humidity, open the motor. To be entitled to any warranty

claims, contact the manufacturer in advance.

These works must be carried out by qualified technicians; in the course of

said works the manufacturer shall instruct said technicians on how to ensure

the explosion protection during reassembly. For the assembly and

disassembly, see the relevant repair instructions.

Loading...

Loading...