46

The drip space in the bearing cap for outflowing old grease is large enough

to collect the outflowing grease during the nominal bearing service life with

state-of-the art regreasing.

See the plate on the motor for the specified lubricating intervals and the type

and quantity of grease to be used. The manufacturer normally uses ESSO

Unirex N3, a lithium complex soap/mineral oil grease.

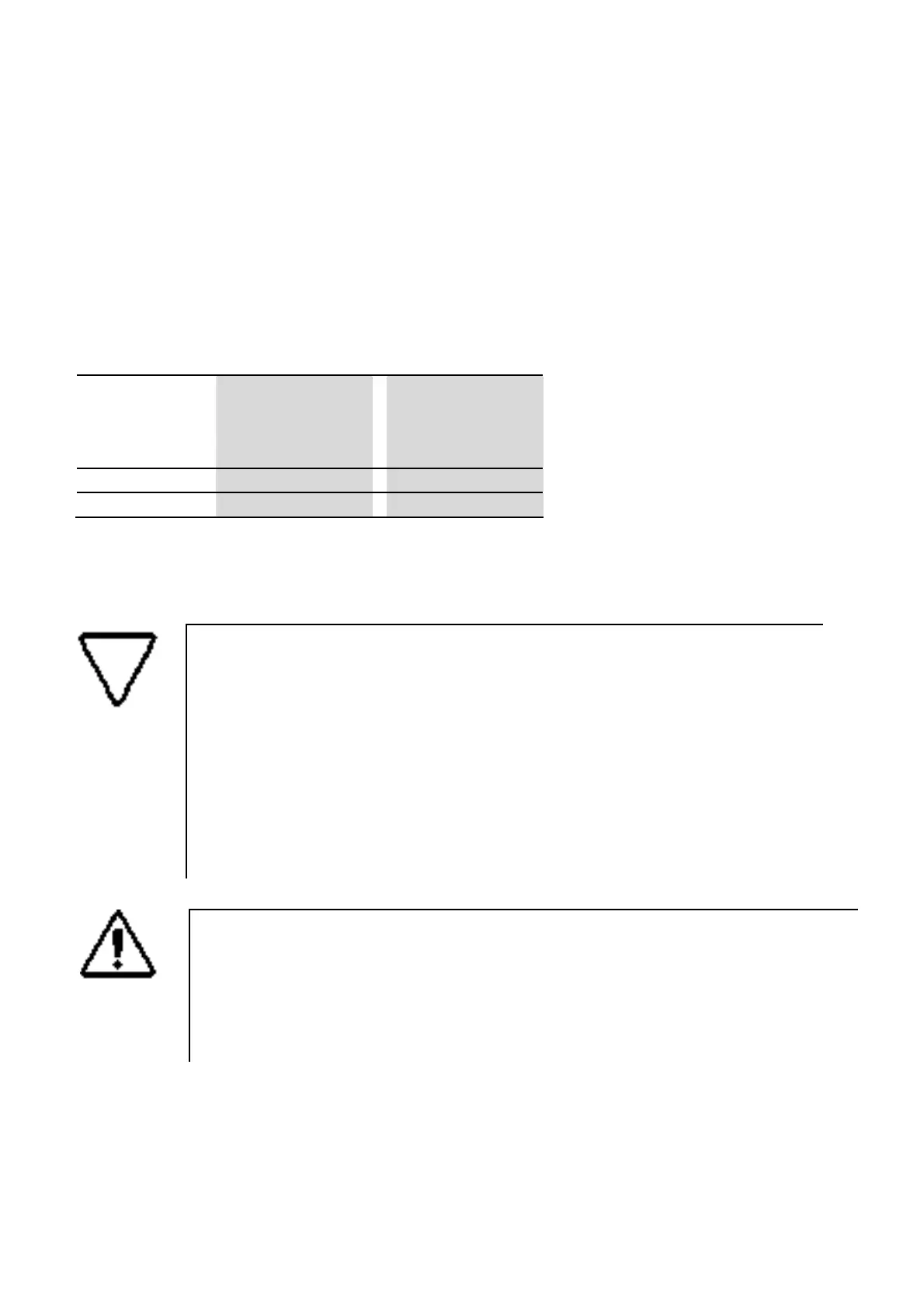

Table 10: Standard regreasing intervals in hours

Ambient

temperature

Rpm up

to 1800 min

–1

Rpm up

to 3600 min

–1

40 °C

5000 h 2500 h

50 °C 2500 h 1000 h

Please note!

In motors with enhanced performance (motor type ...X), in

heavy drive conditions like belt and gear drive with additional

bearing loads and in vertical designs the lubricating intervals

are to be reduced by 50%.

Observe the specified quantity of grease. Overgreasing can

lead to a sharp increase in the bearing temperature and hence

to the failure of the bearing.

Caution!

If regreasing is carried out while the motor is running, provide for

adequate protection against rotating parts!

Only resin-free and acid-free anti-friction bearing grease with a

drop point of approx. 200°C is to be used.

Loading...

Loading...