Safety Information LUM21 HR

4

© Atlas Copco Industrial Technique AB - 9836 1172 05

Air quality

• For optimum performance and maximum ma-

chine life we recommend the use of com-

pressed air with a maximum dew point of

+10°C. We also recommend the installation of

an Atlas Copco refrigeration-type air dryer.

• Use a separate air filter of type Atlas Copco

FIL. This filter removes solid particles larger

than 15 microns and also removes more than

90 % of liquid water. The filter must be in-

stalled as close as possible to the machine/

equipment and prior to any other air prepara-

tion unit such as REG or DIM (please see Air

Line Accessories in our main catalogue). Blow

out the hose before connecting.

Models which need air lubrication:

• The compressed air must contain a small quan-

tity of oil.

We strongly recommend that you install an At-

las Copco oil lubricator (DIM). This should be

set according to air consumption by the air line

tool according to the following formula:

L = Air consumption (litre/s)

D = Number of drops per min (1 drop = 15

mm

3

)

L* 0.2 = D

this applies to the use of long work cycle air

line tools. A single point lubricator type Atlas

Copco Dosol can also be used for tools with

short running cycles.

Information about Dosol settings may be found

under Air Line Accessories in our main cata-

logue.

Lubrication-free models:

• In the case of lubrication-free tools it is up to

the customer to decide on the peripheral equip-

ment to be used. However, it is no disadvan-

tage if the compressed air contains a small

quantity of oil e.g. supplied from a fog lubrica-

tor (DIM) or Dosol system.

• Note – This does not apply to turbine tools,

which should be kept oil free.

Compressed air connection

• The machine is designed for a working pres-

sure of 6–7 bar = 600–700 kPa = 87–102 psi.

• Blow out the hose before connecting.

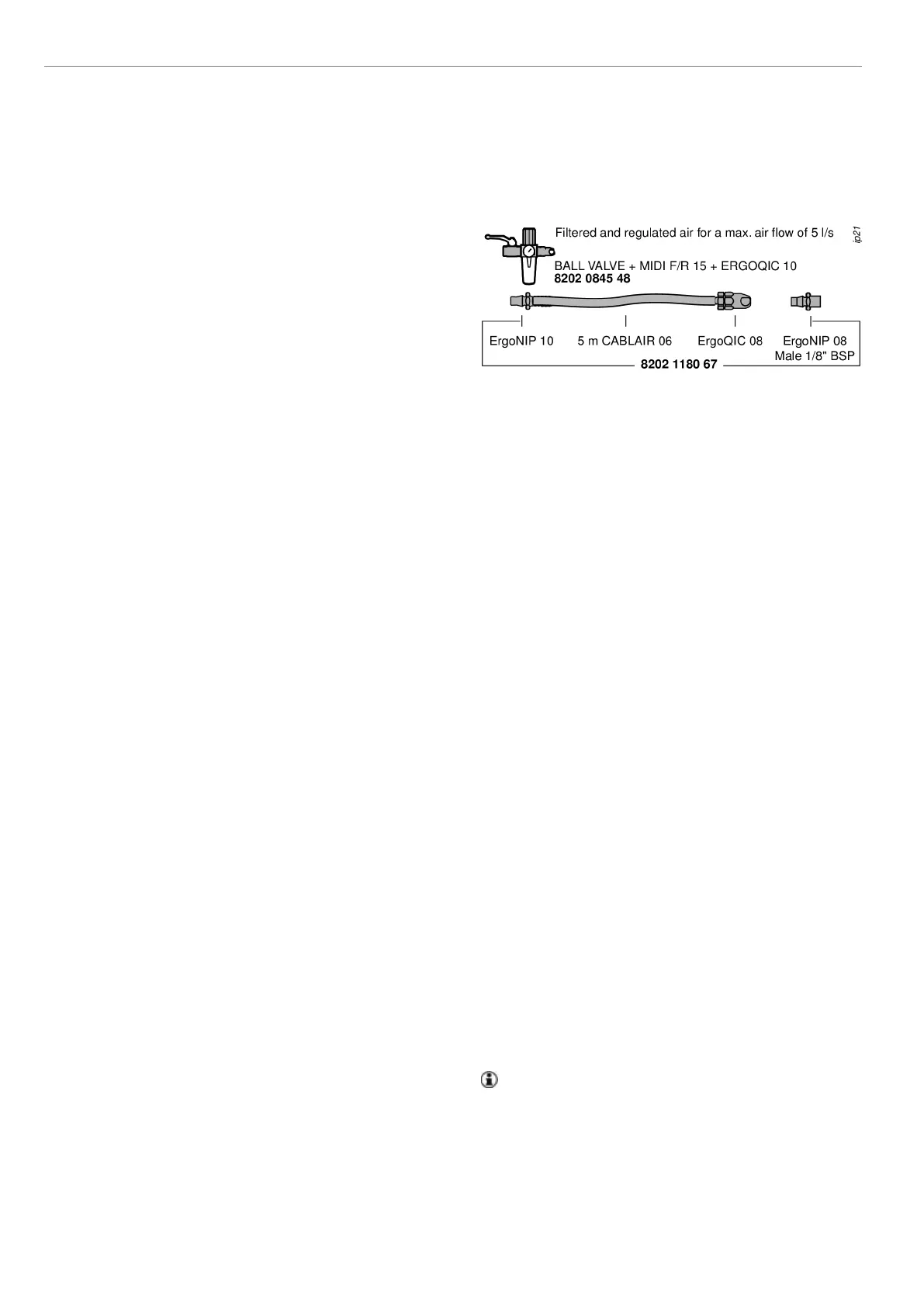

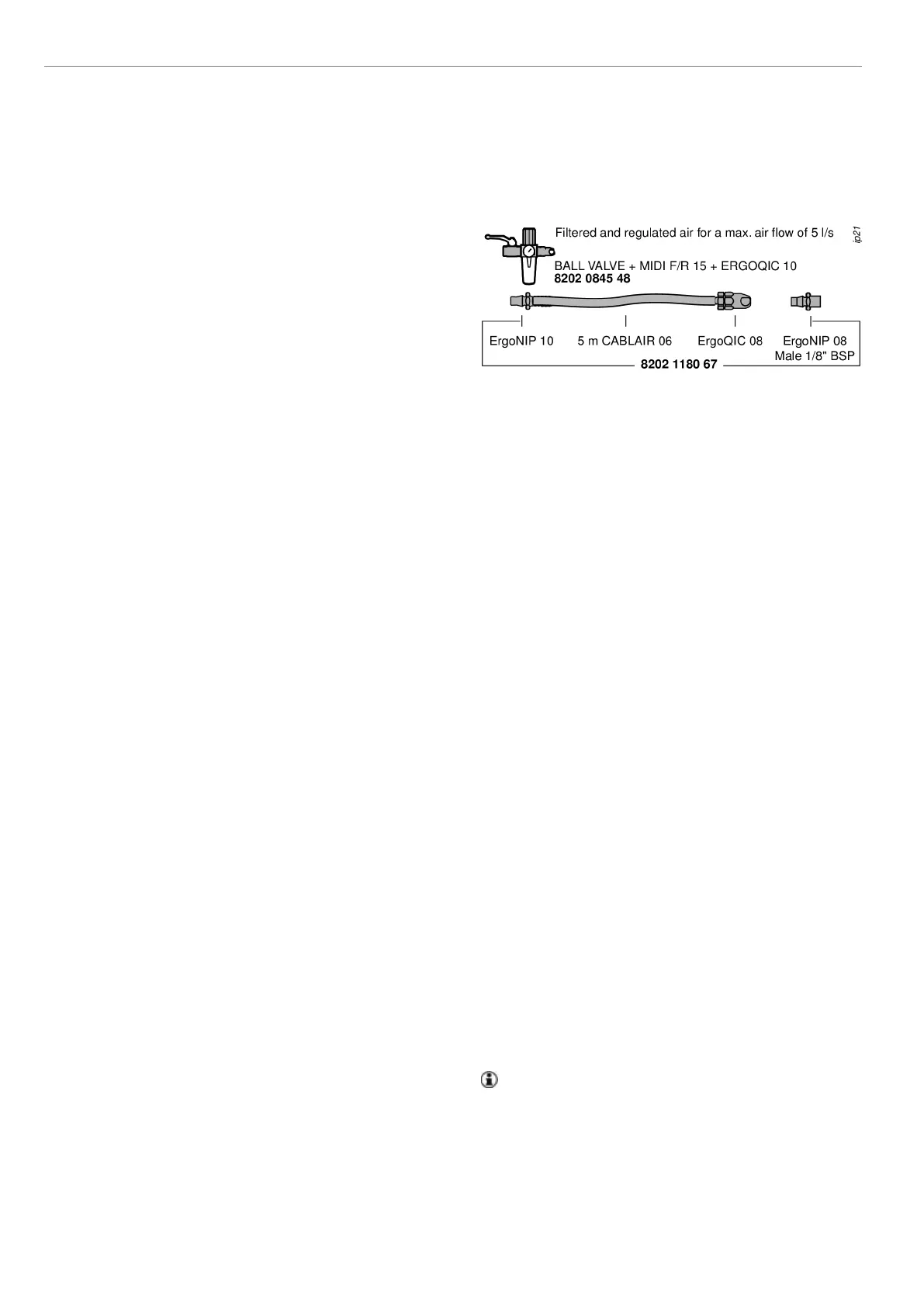

Installation proposal

Choosing the correct couplings, hose and clamps

can be a troublesome digging into details. To save

your time and to ensure correct capacity of the air-

line installation, from the tapping point to the tool,

we offer you an installation proposal.

For more information please read, Atlas Copco In-

dustrial Power Tools catalogue Ordering No. 9837

3000 01.

Handling

Operating instructions

See figure in Service instructions

Tightening torque

For accurate operation and safety, the tightening

torque of the screwdriver must be adjuisted cor-

rectly in relation to the screw joint. Check the

torque specification for the actual joint.

The tightening torque is adjusted by altering the

tension of the clutch spring. Turn the protection

ring until the hole in the clutch housing is free.

Then turn the out going spindle until you can see

the keyhole in the adjustment washer. Turn the ad-

justment key clockwise to decrease and anticlock-

wise to increase the torque. After the adjustment,

turn the protective ring back again.

Verification of tightening torque

Atlas Copco Torque Analyser, ACTA 3000, plus

an appropriately-sized in-line transducer, IRTT to-

gether with the available test joints are recom-

mended equipment.

Torque range of the clutch springs :

Each clutch spring gives a certain torque

range. Don’t adjust the torque over the maxi-

mum recommendation as that might result in

improper function and faster wear of the

clutch.

Loading...

Loading...