2920 1443 01

33

Instruction book

4 MAINTENANCE

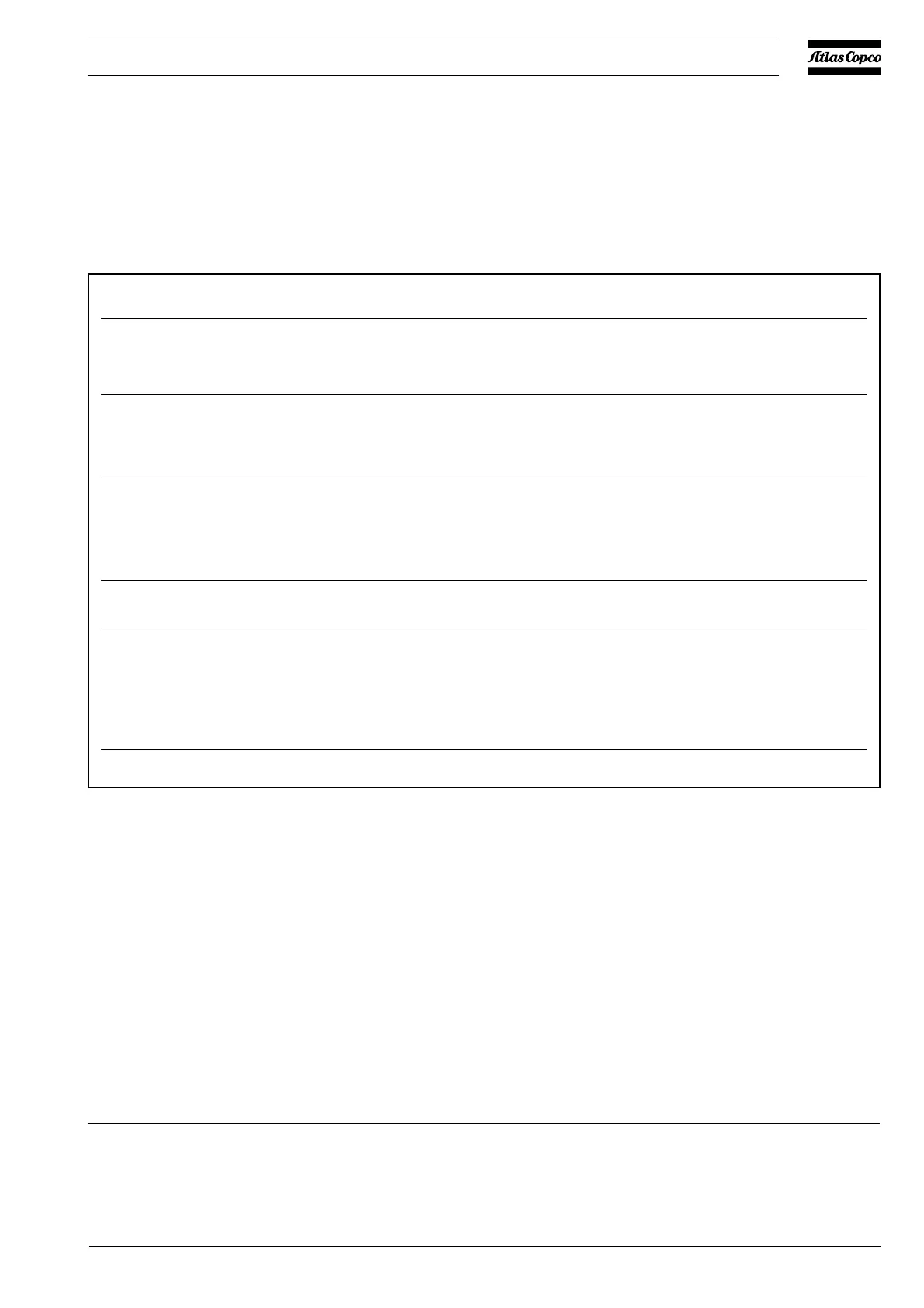

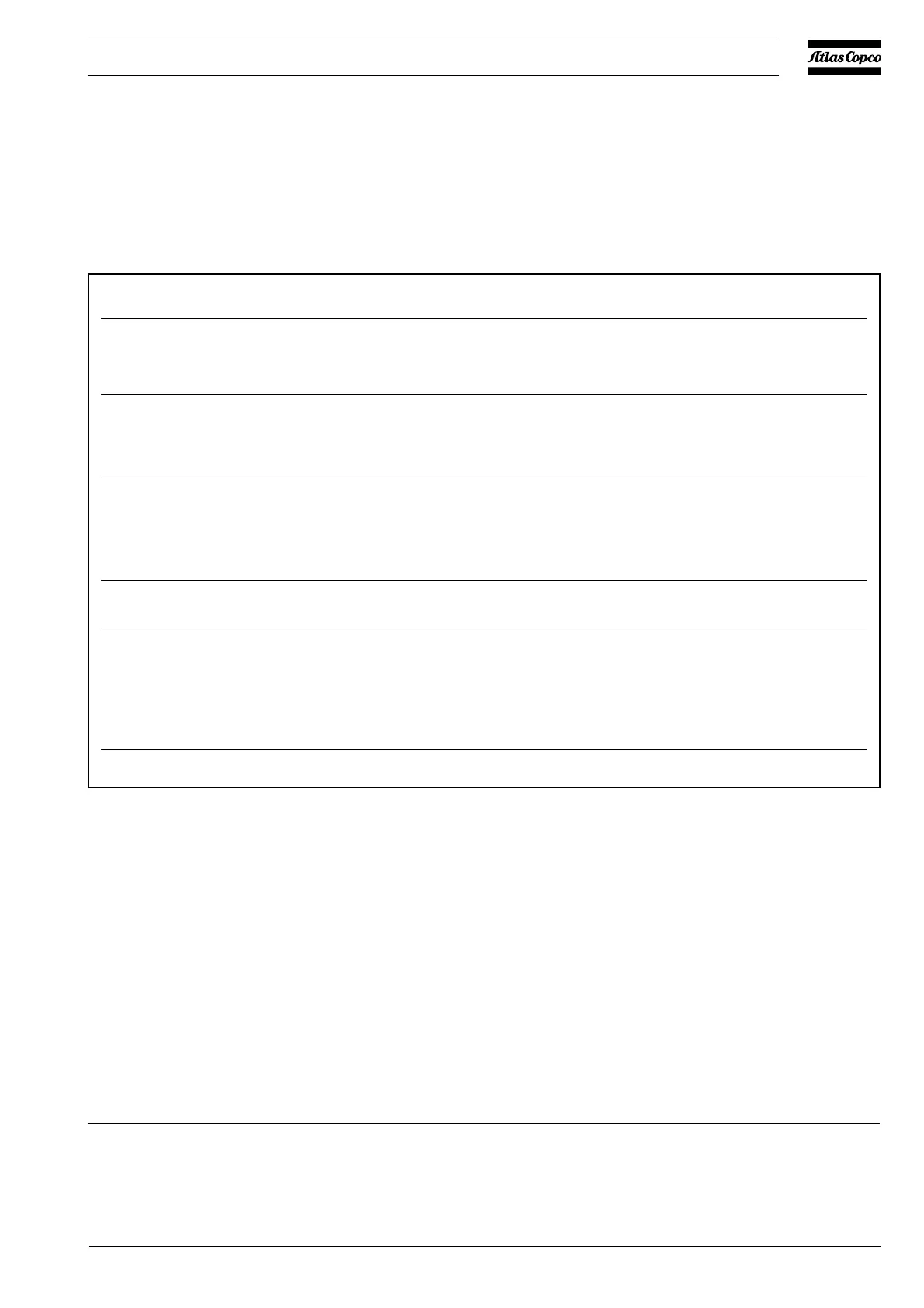

Preventive maintenance schedule 1)

The schedule contains a summary of the maintenance instructions. Read the related notes before taking maintenance measures.

The "longer interval" checks should include the "shorter interval" checks.

Period 2) Running Consult See notes Operation

hours 2) section below table

Daily 4 -- -- Check that the electronic water drains are working correctly

" ------ 3.4 -- Drain condensate after dryer has been stopped

Weekly 50 -- -- Check that moisture indicator shows blue

" ------ -- -- Inspect all air pipes. Tighten leaking connections; replace damaged

gaskets or pipes

Monthly ------ -- 1 Check oil level of worm gear housing

" ------ -- -- Clean dryer

" ------ 3.1 step 14 -- Check pressure differential of rotor compartments. Adjust, if

necessary

3-monthly 500 -- 2 Check safety valve, if installed, by manually blowing air

Yearly 8000 -- 3 Change oil of worm gear housing

" ------ -- -- Inspect drain system

" ------ -- 4/5 Check cooling efficiency of regeneration air cooler and pressure-

test cooler

" ------ -- -- On air-cooled dryers, clean regeneration cooler externally

2-Yearly 16000 -- -- Replace demister sponge

Notes

1. Dryers equipped with a worm gear housing as shown in Fig. 2.16 are filled for life and do not need maintenance. On dryers

equipped with a worm gear housing as shown in Fig. 2.15, stop the compressor and depressurize the dryer, remove plug (6-

Fig. 2.15) and check that the oil is level with the bottom of the plug hole. Top up, if necessary, with oil as specified in note 3.

2. Operate the valve several times for some seconds while there is pressure in the system, by screwing the cap of the valve anti-

clockwise with a gloved hand. Retighten the cap by hand after testing.

3. Dryers equipped with a worm gear housing as shown in Fig. 2.16 are filled for life and do not need maintenance. On dryers

equipped with a worm gear housing as shown in Fig. 2.15, replenish the housing after draining to level with the hypoid gear

lubricant Roto M. Roto M can be ordered at Atlas Copco in 1-l cans, ordering number 2908 8506 00

4. The temperature difference between the incoming water and the outgoing air of the cooler during the loading periods of the

compressor should never exceed 10°C. A contact thermometer should be used to measure the temperature of the pipes. Have

the cooler cleaned if the cooling efficiency is insufficient.

Note: In checking the cooling efficiency of the compressor coolers of combined ZR3/ZR5-MD units, the temperature difference

of 25°C as mentioned in the instruction book of the compressor should be replaced by 10°C.

5. Preferably to be carried out by an Atlas Copco Service representative.

Footnotes chapter 4

1) Use only authorized parts. Any damage or malfunction caused by the use of unauthorized parts is not covered by Warranty or Product

Liability.

2) Whichever interval comes first.

Loading...

Loading...