2920 1443 01

8

Instruction book

1.4 Electrical system

The motor must be wired to the electrical equipment of the

compressor as shown on the relevant circuit diagram.

1.4.1 MD400/800/1300/2500 W VSD (Figs. 1.13 up

to 1.15)

The worm gear motor must be connected to the frequency

converter for the dryer (A21) in the electrical cabinet of the

compressor. The rotor speed of the dryer depends on the speed

of the compressor motor. When the compressor runs at

maximum speed, the dryer will also run at maximum speed and

vice versa. The dryer motor stops when the compressor runs

unloaded.

1.4.2 All other MD dryers (Figs. 1.9 up to 1.12)

The worm gear motor (M40) is connected in the circuit of the

compressor air pressure switch or, in case of an Elektronikon-

controlled compressor, in series with a contact of the loading/

unloading relay. Thus the worm gear motor stops running when

the compressor is unloaded. This condition is required since

hot compressed air for regenerating the rotor is not available

when the compressor runs unloaded.

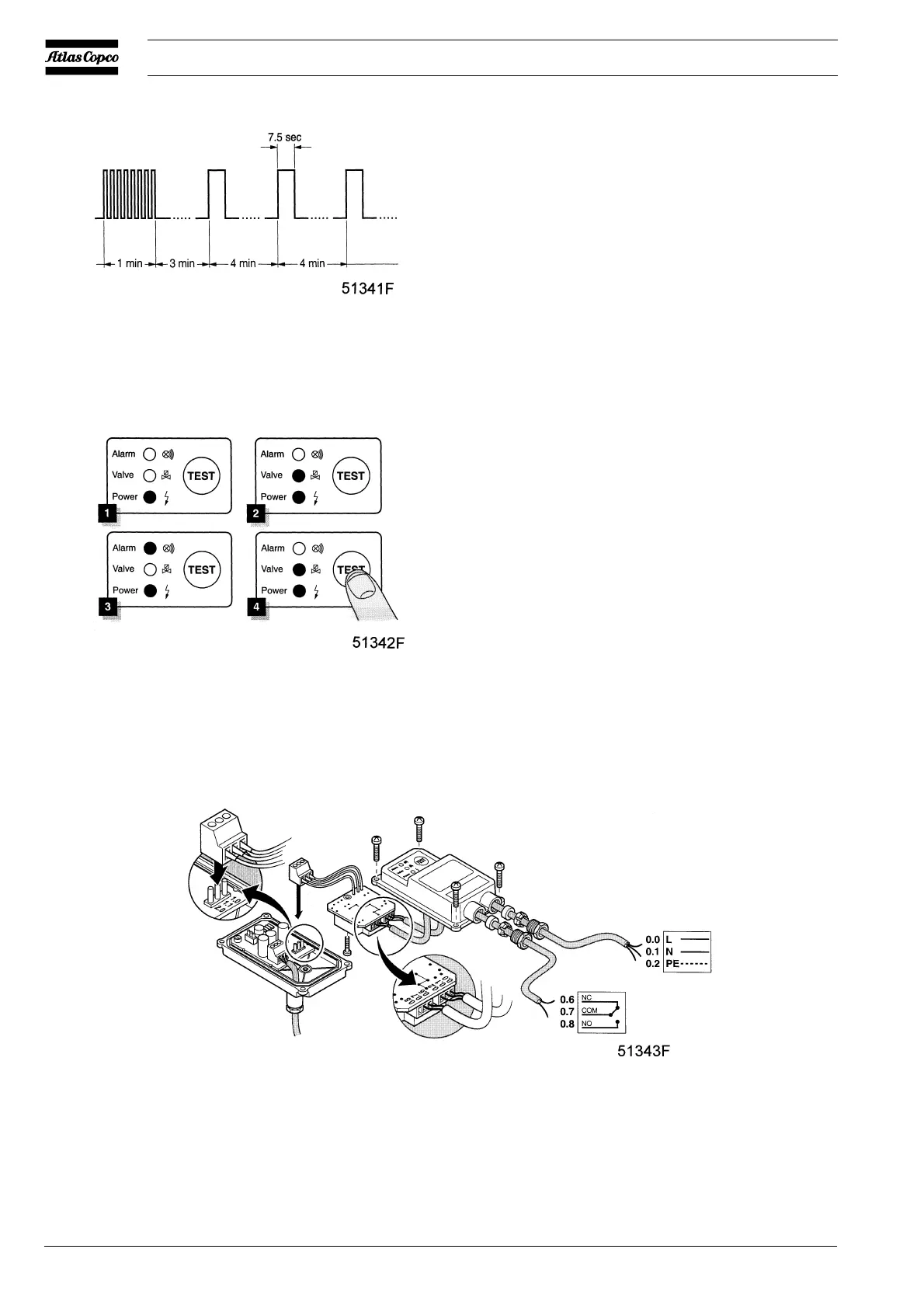

Fig. 1.6 Drain frequency during alarm condition

Fig. 1.7 Control panel

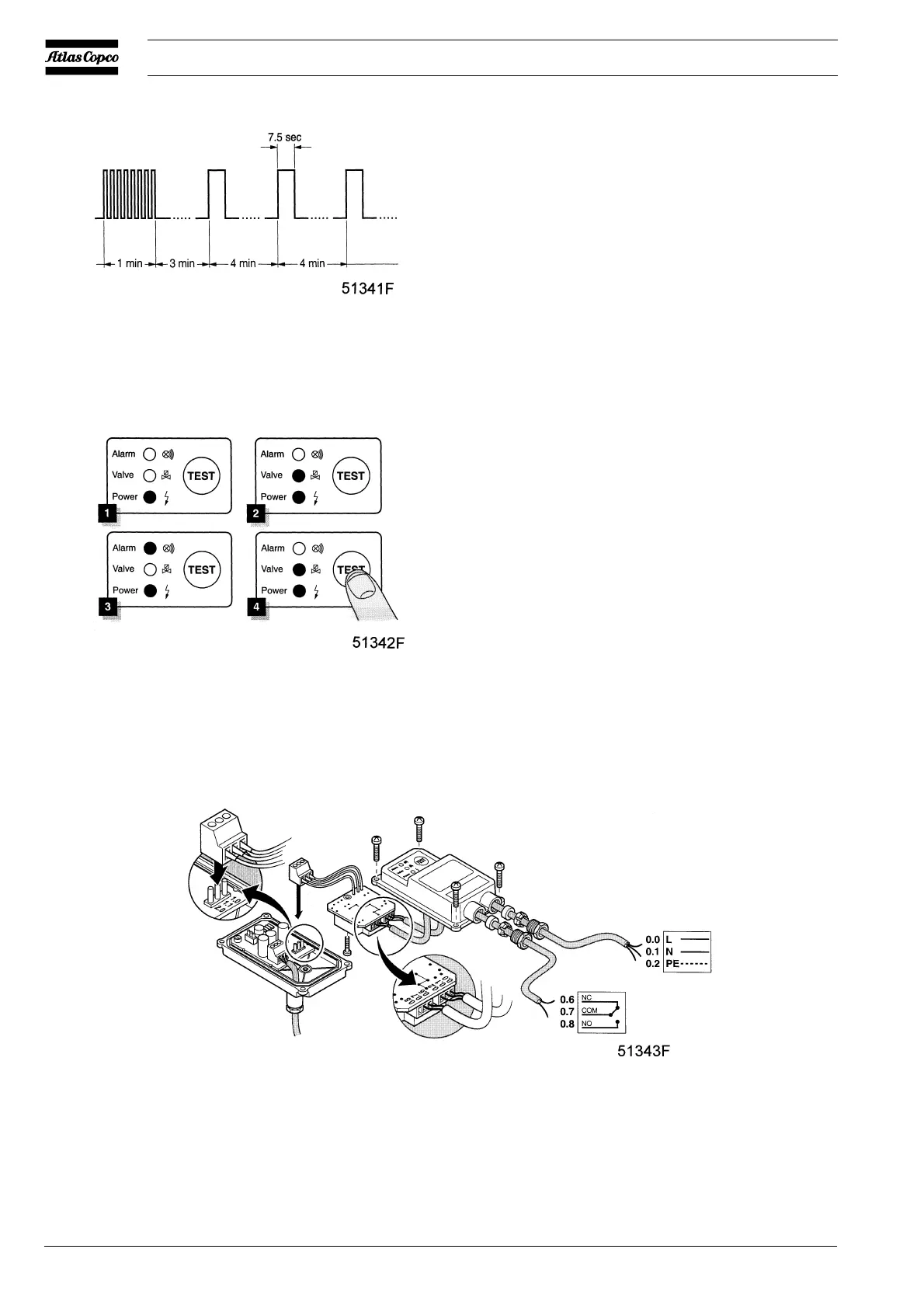

0.0 Line terminal

0.1 Neutral terminal

0.2 Earth terminal

0.6 Normally closed terminal

0.7 Common terminal

0.8 Normally open terminal

Fig. 1.8 Electrical connections

Loading...

Loading...