2920 1443 01

4

Instruction book

Rotor

The sections of drying material are wrapped onto a core and

contained in a jacket. The power of the motor is transmitted to

the rotor, through a pin-type coupling, a worm gear and a drive

shaft.

A lip-seal (29-Fig. 1.4), fitted on the rotor jacket, separates the

wet and dry sides of the rotor. The lip of the seal rests on the

surface of a ring clamped between the flanges of the vessel.

Sealing sectors

Both end faces of the rotor are provided with a sealing sector

for conducting the regeneration and cooling air flows through

the rotor. The sector on the regeneration air inlet is spring-

loaded. Both sectors slide on an inner and an outer ring fixed to

the rotor. A slight clearance is left between the faces of the

sectors and the rotor end faces.

The regeneration air inlet sealing sector covers a segment of 90

degrees of the dry side rotor face and is provided with a filter.

The outlet sealing sector is bigger, as it also accommodates the

cooling sector.

An Electronic Water Drain (EWD) is connected to the lower

part of the regeneration air compartment of the dryer.

Electrical control

The operation of the rotor motor is controlled by the electric

regulator of the compressor.

By-pass system

The dryers are standard equipped with a by-pass system

including an air inlet valve, an air outlet valve and a by-pass

valve. A regeneration air shut-off valve and a connection pipe

set is also included in the dryer package. A safety valve may

also be fitted.

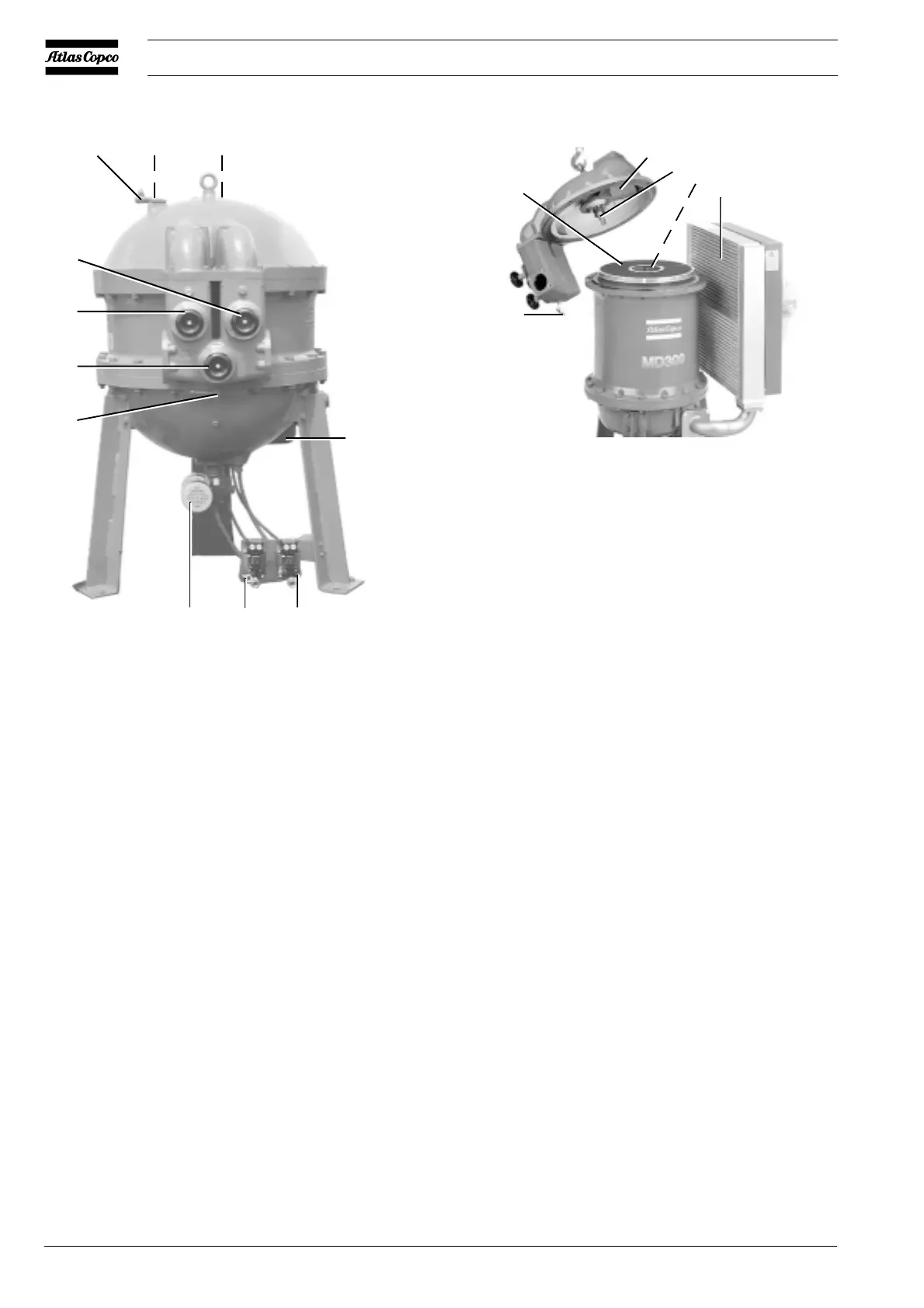

1 Valve for (-) connection, pressure differential gauge

2 Valve for (+) connection, pressure differential gauge

3 Throttle valve

4 Regeneration air cooler

5 Electronic Water Drain, inlet air water separator

6 Electronic Water Drain, regeneration air water separator

7 Rotor motor with incorporated gearbox

8 Manual drain valve, dryer inlet water separator

9 By-pass valve

10 Air outlet valve

11 Air inlet valve

Fig. 1.2 General view of MD600 W

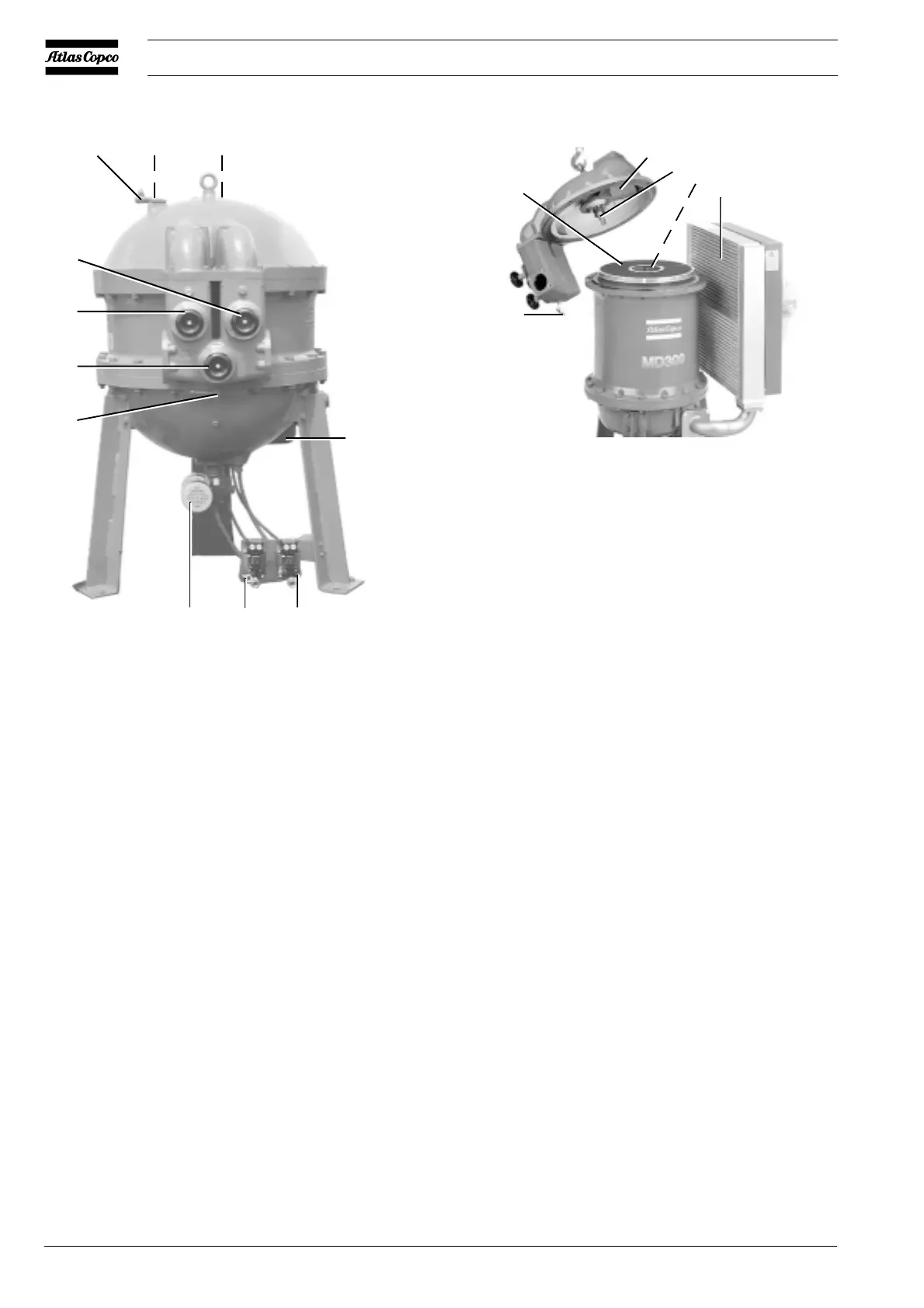

1 Regeneration air sector

2 Nozzle

3 Ejector

4 Regeneration air cooler

5 Manual drain valve, dryer inlet water separator

6 Rotor

Fig. 1.3 Inside view of MD300

7

6

5

1

23

4

11

10

9

8

51337F

1

2

3

4

5

6

51338F

Loading...

Loading...