- 46 -

Engine oil level check

Consult the Engine Operation Manual for the oil

specifications, viscosity recommendations and oil change

intervals.

For intervals, see section “Maintenance schedule” on

page 42.

Check engine oil level according to the instructions in the

Engine Operation Manual and if necessary top up with oil.

Engine oil and oil filter change

The table below shows the oil change interval according

to the sulfur content in the fuel.

Engine coolant specifications

The use of the correct coolant is important for good heat

transfer and protection of liquid-cooled engines. Coolants

used in these engines must be mixtures of good quality

water (distilled or de-ionised), special coolant additives

and if necessary freeze protection. Coolant that is not to

manufacturer's specification will result in mechanical

damage of the engine.

The freezing point of the coolant must be lower than the

freezing point that can occur in the area. The difference

must be at least 5°C. If the coolant freezes, it may crack

the cylinder block, radiator or coolant pump.

Consult the engine's operation manual and follow the

manufacturer's directions.

Specifications PARCOOL EG

PARCOOL EG is the only coolant that has been tested and

approved by all engine manufacturers currently in use in

Atlas Copco compressors and generators.

Atlas Copco's PARCOOL EG extended life coolant is the

new range of organic coolants purpose designed to meet

the needs of modern engines. PARCOOL EG can help

prevent leaks caused by corrosion. PARCOOL EG is also

fully compatible with all sealants and gasket types

developed to join different materials used within an

engine.

PARCOOL EG is a ready to use Ethylene Glycol based

coolant, premixed in an optimum 50/50 dilution ratio, for

antifreeze protection guaranteed to -40°C.

Because PARCOOL EG inhibits corrosion, deposit

formation is minimized. This effectively eliminates the

problem of restricted flow through the engine coolant

ducts and the radiator, minimizing the risk for engine

overheating and possible failure.

It reduces water pump seal wear and has excellent stability

when subjected to sustained high operating temperatures.

PARCOOL EG is free of nitride and amines to protect

your health and the environment. Longer service life

reduces the amount of coolant produced and needing

disposal to minimise environmental impact.

To ensure protection against corrosion, cavitation and

formation of deposits, the concentration of the additives in

the coolant must be kept between certain limits, as stated

by the manufacturer's guidelines. Topping up the coolant

with water only, changes the concentration and is

therefore not allowed.

Liquid-cooled engines are factory-filled with this type of

coolant mixture.

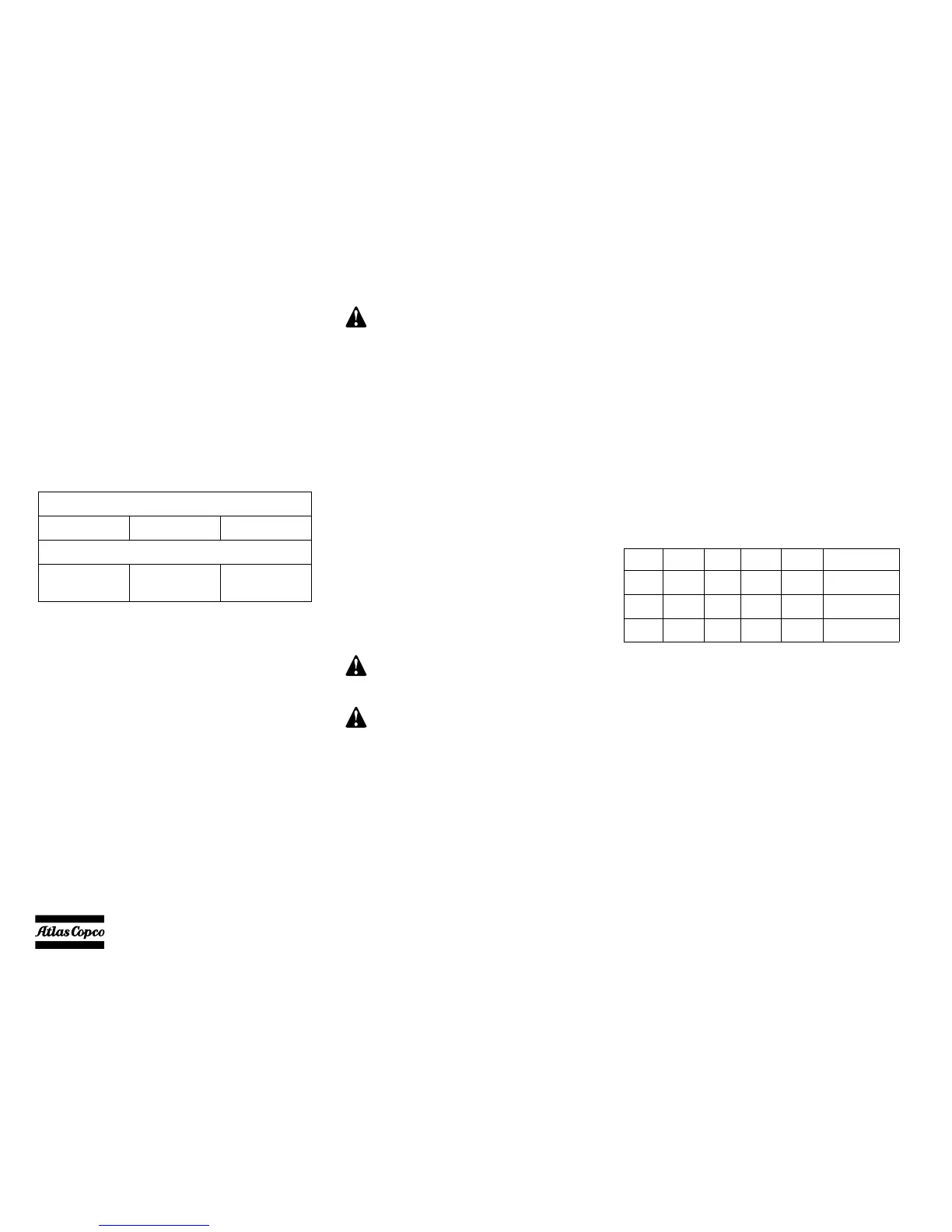

Sulfur content in fuel, by weight

<0.5% 0.5-1.0% >1.0%

Oil change interval, reached first in operation

500h /

12 months

250h /

12 months

125h /

12 months

Never remove the cooling system filler

cap while coolant is hot.

The system may be under pressure.

Remove the cap slowly and only when

coolant is at ambient temperature. A

sudden release of pressure from a heated

cooling system can result in personal

injury from the splash of hot coolant.

It is strongly recommended to use Atlas

Copco branded coolant.

Never mix different coolants and mix

the coolant components outside the

cooling system.

Never replace the coolant filter on the

engine! Just replace the coolant every 5

years or after 10.000 running hours.

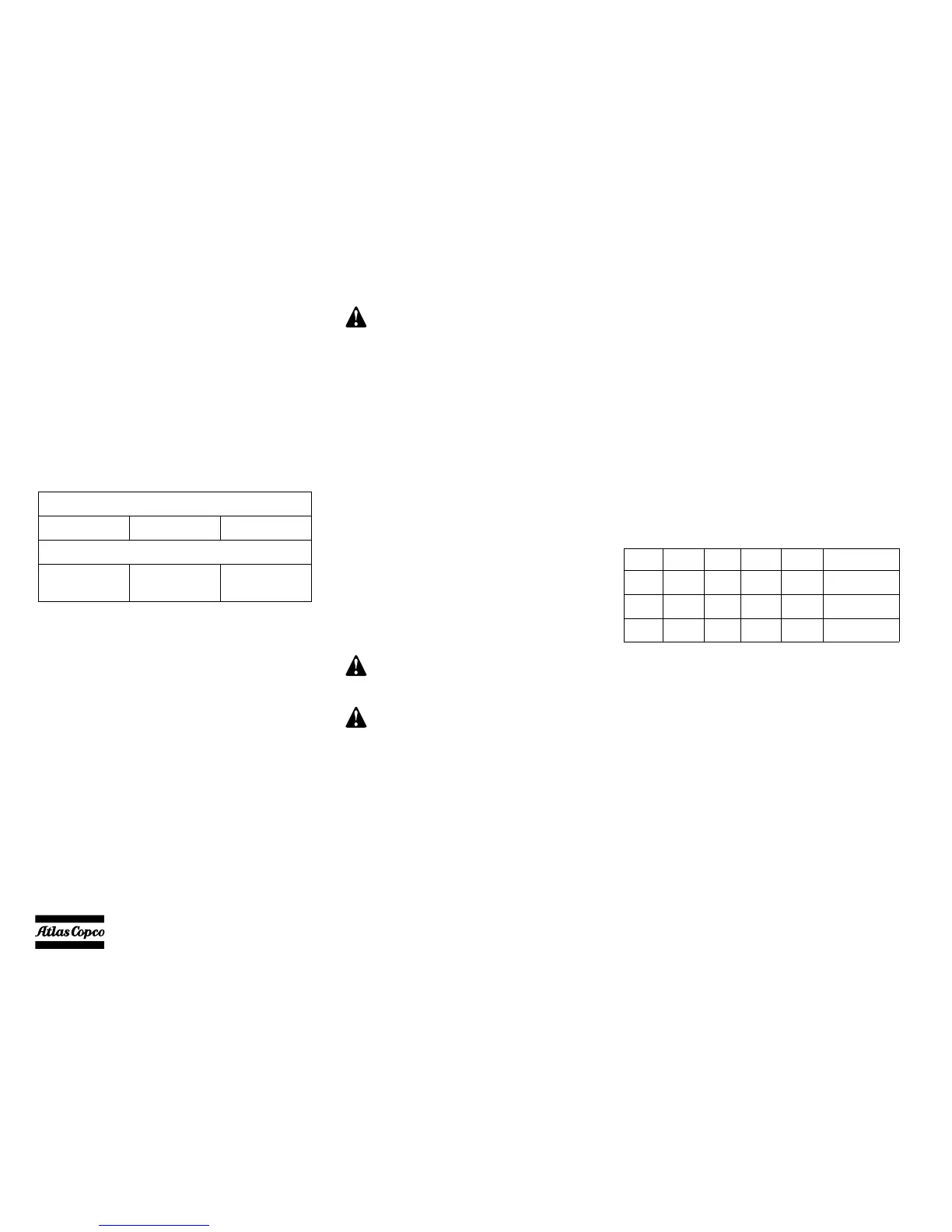

Liter US gal Imp gal cu.ft Order number

can 5 1.3 1.1 0.175 1604 5308 00

can 20 5.3 4.4 0.7 1604 5307 01

barrel 210 55.2 46 7.35 1604 5306 00

Loading...

Loading...