- 46 -

Notes

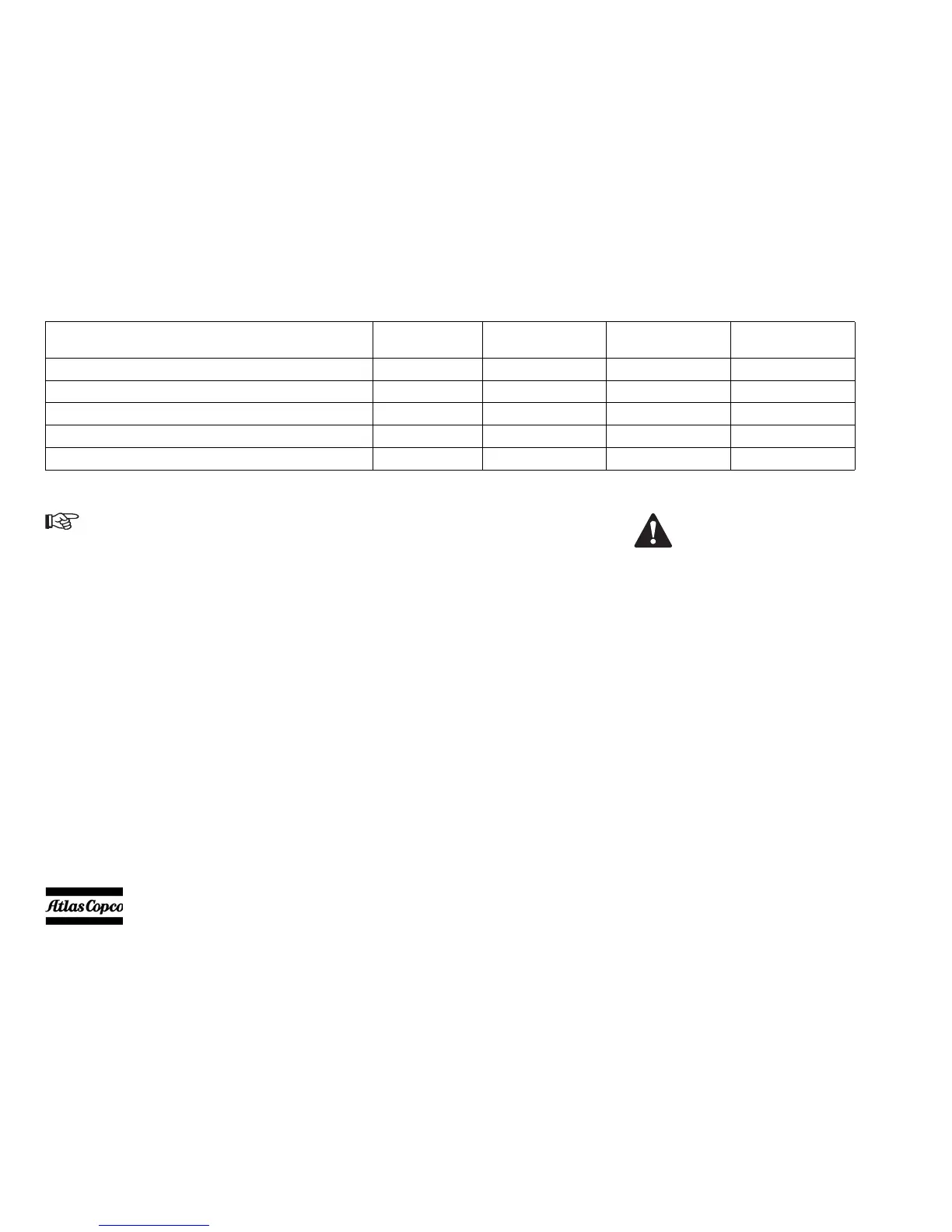

Maintenance schedule

(continuation of page 45)

Daily 50 hours after initial

start-up

Every 6 months or

500 hours

Yearly or every

1000 hours

Fuel filter (3) (7) Replace Replace

Engine inlet and outlet valves (3) Adjust Adjust

Filter element from regulating valve Replace

Flow restrictor in oil scavenge line Clean

Inspection by Atlas Copco Service Technician Inspection

1. More frequently when operating in a dusty environment.

2. Replace the element when the pressure drop exceeds 0.8 bar (11.6 psi).

3. Refer to the engine operation manual.

4. 200 / 500 hours is only valid when using PAROIL 15W40.

5. Check coolant every year. Change coolant every 5 years.

6. Use Atlas Copco oil filters, with by-pass valve, as specified in the parts list.

7. Replace the fuel filters regularly. Gummed or clogged filters mean fuel starvation and reduced

engine performance. The quality of the fuel determines the frequency of renewal.

8. See section Oil specifications.

9. The following part numbers can be ordered from Atlas Copco to check on inhibitors and freezing

point:

• 2913 0028 00 refractometer

• 2913 0029 00 pH meter.

10. See section Safety valve.

11. See section Before starting.

12. Replace all rubber flexibles each 6 years, according to DIN 20066.

Keep the bolts of the housing, the lifting

beam, tow bar and axles securely

tightened. For torque values see section

Technical specifications.

Loading...

Loading...