1. Purpose

The ecological warm water boiler ATMOS is determined for heating in the one-family houses and

other similar buildings. The boiler types are used according to the required power output from 20 up to

75 kW.

The boilers are constructed especially for combustion of lump wood. All kind of dry wood can be used,

especially wood billets with the max. length 330 – 1000 mm according to the boiler type. Also wood

blocks with bigger diameter can be used, which reduces the nominal power but prolongs the burning

time. The boiler is not suitable for combustion of sawdust and wood waste – these can be used only in

small volume – MAX. 10 % - together with wood billets.

The huge fuel hopper will reduces the preparatory operations of the wood, because bigger billets can

be used. In this way, the physical effort can be eliminated and the time necessary for fuel cutting saved.

2. Technical data see page 3

Notice

The wood billets with bigger diameter must be divided into halves or quarters (according to the ope-

rating demands regarding the nominal power of the boiler). Hard and soft wood can be used.

The wood must be dry! The power output of the boiler depends on the moisture rate of

the wood. The power and the function of the boiler can be secured just if the moisture is

12 - 20 %.

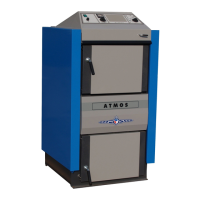

3. Technical description

The boilers are constructed for combustion of wood. The combustion is based on the principle of

generator gasification using the exhaust ventilator, which blows the combustion air into the combustion

chamber.

The boiler body is a welded drum made of steel plates 3 – 6 mm thick, furthermore a fuel hopper with

a fire-resistant shaped piece in the lower part, which has a longitudinal hole for gas and waste gas flow.

The cumbustion chamber below is fitted with ceramic shaped pieces.

In the rear space of the boiler body there is a vertical fuel channel with a firing safety valve in the

upper space. The rear part of the main flue is equipped with a exhaust tube connected with the chimney.

The front of the boiler is fitted with a filling door upon an ash pan door.

The firing safety valve pull rod is situated on the upper front of the control panel.

The exterior of the boiler body is insulated with mineral felt placed under the outside metal jacket.

On the boiler top you will find the control panel for the elektrical-mechanical control.

At the back, there are the inlet channel for the primary and secondary air with a ventilator and a valve.

The primary and secondary air is pre-heated to a high temperature.

The boiler construction gives the following advantages:

The high temperature combustion with the generator function proceeds in a ceramic combustion

chamber with lateral primary air inlet into the boilers GS.

2

Loading...

Loading...