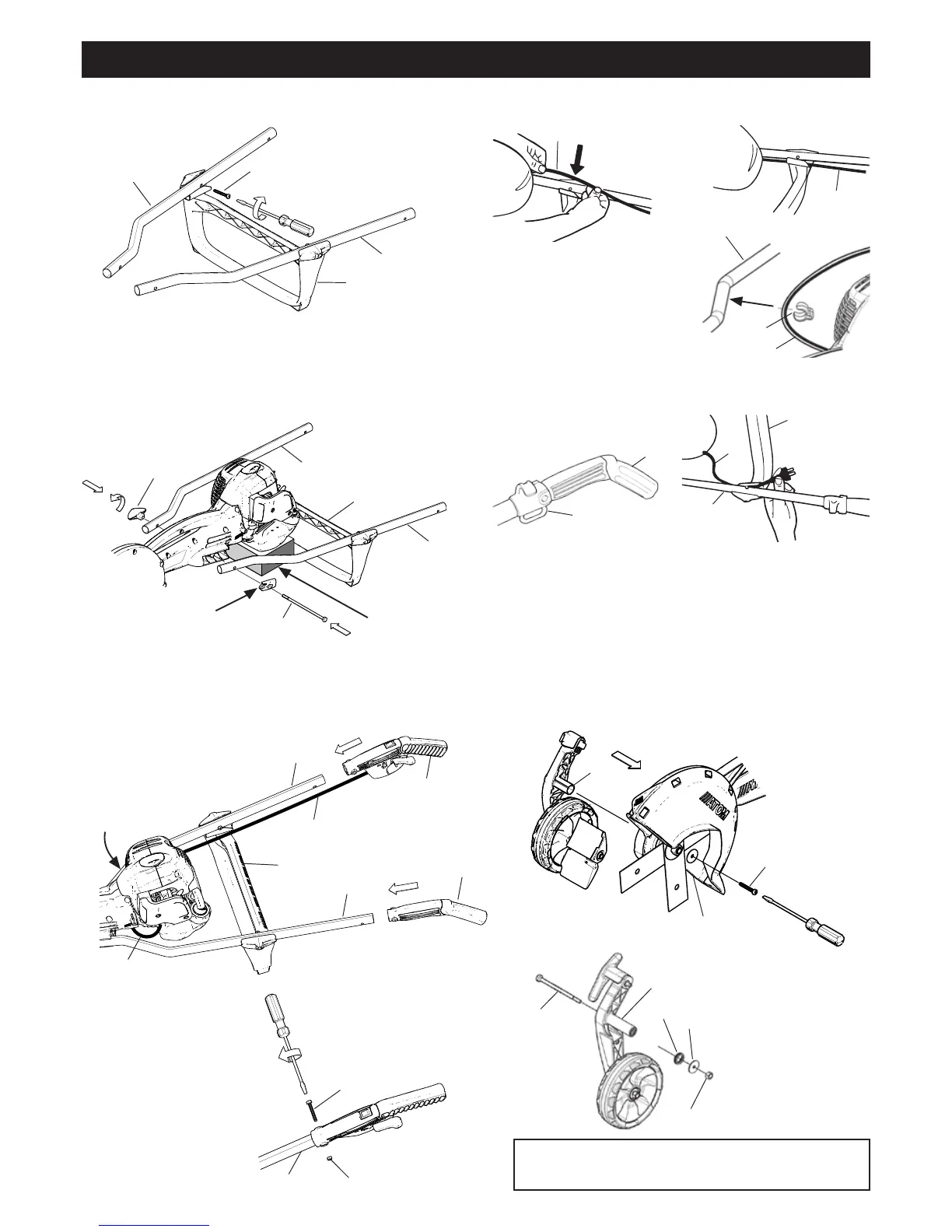

FIG 14

FIG 15

FIG 18

ASSEMBLING HANDLES ON LAWN EDGERS & TILLERS

PAGE 4

FIG 17

TOP VIEW

7

3

10

10

14

1. Using blade screwdriver (or Torx-25 screwdriver). Use M5 x

36mm screws #8 to screw 2 handle tubes #3 & #5 to cross

brace #7. Fig 10.

FIG 10

8

5

7

3

2. Place lawn edger or tiller body on bench or floor. With

approximately 75mm–100mm (3”–4”) spacer under engine.

Fit handle tubes assembled with cross brace #7 to edger or

tiller body as shown with bolt #1 and tighten large plastic

wing nut #6. Fig 11. For professionals, firstly put front ends of

tubes through AV rubbers #7 & #8 in Fig.7 on page 3.

FIG 11

6

1

SPACER

BLOCK

3. Looking down from rear of edger or tiller, feed RH hand grip

#11 with throttle trigger, throttle cable #10 and switch wire

#10 under engine, and over top of cross brace #7 and push

RH trigger hand grip #11 onto end of RH handle tube #5. Fig

12. (Note Electric edgers/Tillers have no (separate) switch

wire). Then also push LH hand grip #13

onto end of LH handle tube #3.

FIG 12

4. Fit and hold M5 loc-nut

#9 (with nylon part of nut

facing away from tube) into

hex recess of hand grip

and insert M5 x 36mm #8

through hand grip (from

other side), through tube

and tightly screw up. Fig 13.

Repeat for other hand grip.

10

5

10

11

3

10

FIG 13

5 9

5. Clip throttle cable #10 and switch wire into place. Fig.14

and 15.

6. Use cable and switch wire C-clip

#14 to retain throttle cable

#10 and switch wire against

RH handle tube #5 adjacent

engine. Fig 16.

7. ELECTRIC EDGERS & TILLERS

Clip cord anchor #12 onto LH handle grip #13 and fit

together onto LH tube #3. Fig 17. Fit screw #8 with nut #9.

Clip power plug cord #14 of motor into place on LH topside

of cross brace #7. Fig 18.

5

14

FIG 16

13

12

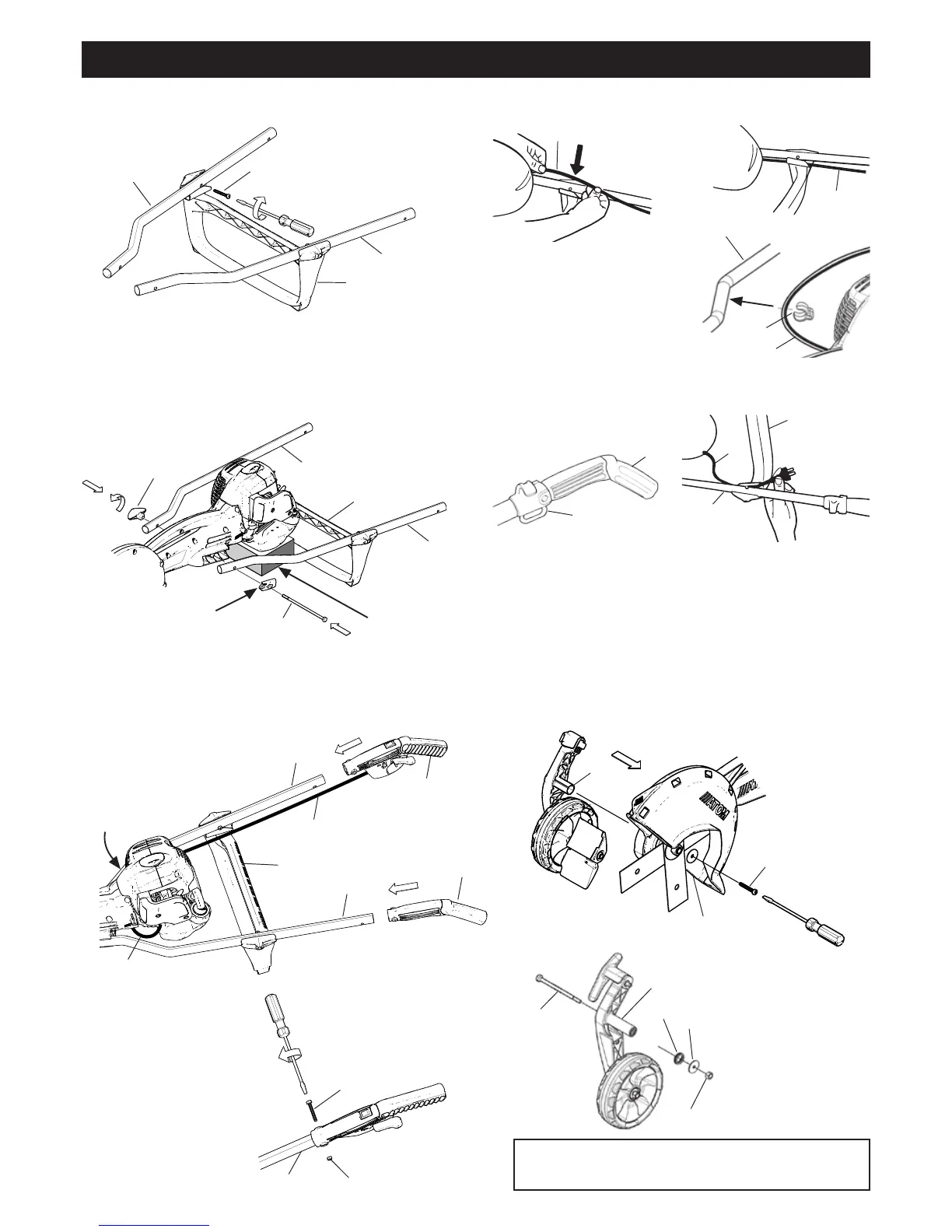

8. Fit wheel arm assembly pivot axle #18 into RH side of

main body of machine.

5

7

3

7

8

10

EDGER INSTRUCTIONS CONTINUED PAGE 6

TILLER INSTRUCTIONS CONTINUED PAGE 7

13

NOTE: ARROW TO FRONT

15

18

16

17

24

FIG 20

8(a) Wheel arm without bolt.

On LH side insert M5 x 36mm screw #8 through fixed

encapsulated washer #26, and tighten screw. Fig.19.

8

26

FIG 19

8(b) Wheel arm with

bolt. Insert bolt #15

into wheel arm, and on

LH side fit washer #16

(if washer not already

fitted) and nut #17 onto

protruding bolt. Tighten

nut. Fig.20.

WHEEL ARM ASSEMBLY

18

Loading...

Loading...