PAGE 5

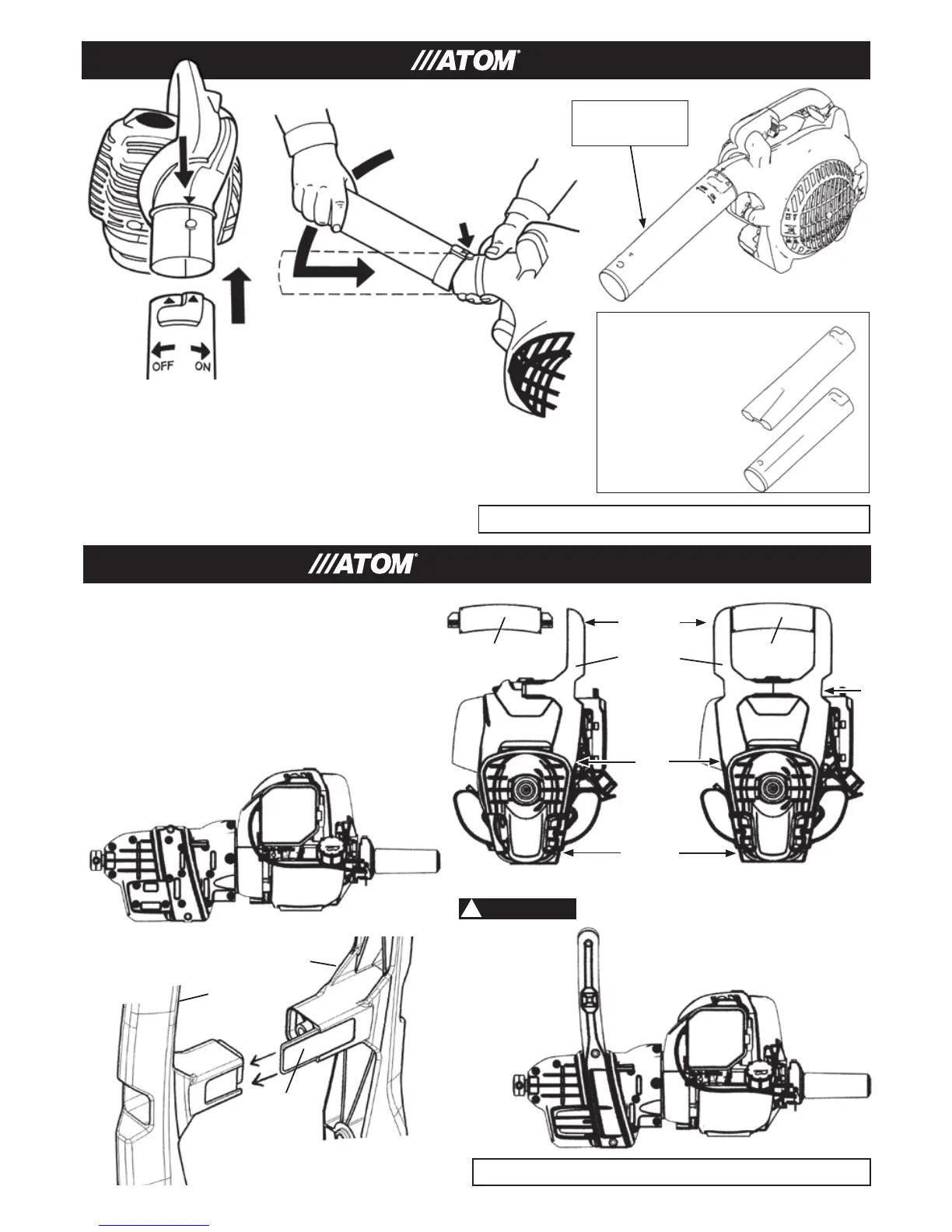

FIG 35

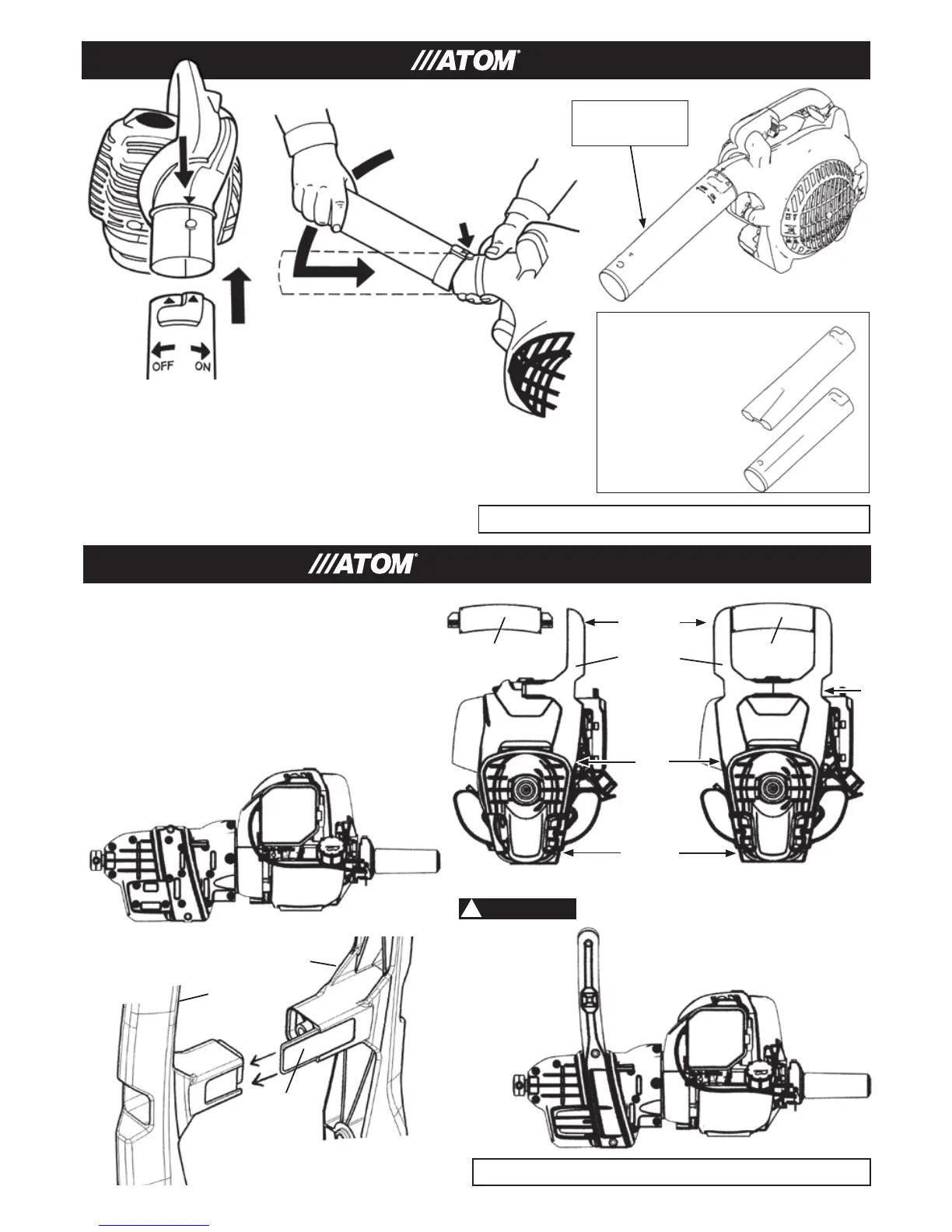

ASSEMBLING DRILLMASTER ENGINE DRILLS

ASSEMBLING AIRLIFT BLOWERS

Use Torx 25 screwdriver or straight blade screwdriver.

Fit 7 screws M5 x 36mm (supplied) to assemble as

follows:

1. Fig.35. Unit shown without main support handle.

2. Fig.36. Fit LH main support handle #8 into casing.

Insert screws #1 and #2 and tighten. Fit handle grip

#10 with screw #3 to LH support handle #8.

3. Fig.37. Carefully slide labelled Handle Rib #11 into

top and bottom groove in LH handle #8.

4. Fig.38. Insert screws #4, #5 and #6 and tighten.

In LH handle #8 screw

centre bracket

together

with screw #7.

FIG 39

1. Align blower tube to match tube arrows. Figs.32A and

32B.

With one hand squeeze casings together and push

blower tube in and down. Fig.32B.

Twist blower tube clockwise to lock in position. Fig.33.

2. For POWERFUL AIRLIFT use blower with one tube

only as shown in Fig.33. This very efficiently completes

blowing jobs quicker.

6

5

4

7

FIG 32B

3

2

1

FIG 36

FIG 38

FIG 37

BLOWER INSTRUCTIONS CONTINUE ON PAGE 8

DRILL INSTRUCTIONS CONTINUE ON PAGE 8

Fully assembled drill

10 10

98

Check that all screws #1-#7 are tight.

8

9

11

! WARNING

FIG 32A

FIG 34

Because Atom AIRLIFT blowers have

such a powerful airblast, the

second tube and fishtail nozzle

are NOT necessary to use.

FIG 33

SPARE BLOWER

TUBE

FISH TAIL

NOZZLE

For best blowing

fit one tube only.

Loading...

Loading...