EDGING INSTRUCTIONS

(

CONTINUED

)

PROBLEM CAUSE ACTION

1. Blades do not turn Loose blade nut or incorrect assembly. Tighten blade nut (or add washer under nut).

when operating

Blade cover filled with dirt/grass/mud. Clean.

Blade stops under load when blade depth is too low. Cut less depth.

Clutch slipping.

Missing blade washers.

Cut less depth or clean. Instal washers.

2. Motor lacks power or blade stops rotating Cutting too deep. Raise cutting depth and see (1) above.

3. Heavy vibration Wrong blade fitted. Only use ORIGINAL Atom blade set #43105

Worn clutch or clutch drum or damaged drive. Take to service dealer.

4. Engine will not run or runs and stops Ignition switch is OFF. Turn switch on.

Choke ON. Push choke to OFF position.

Partially empty fuel tank. Fill tank.

Primer bulb not pushed enough times. Press primer bulb fully and slowly 5 times.

Engine is flooded Use starting procedure without choke.

PAGE 6

TROUBLESHOOTING TIPS

MAINTENANCE INSTRUCTIONS

! NOTE

Keep the inside of blade

guard clean, especially in

muddy conditions. A clogged guard can slow

down or stop blade rotation and may cause

damage to automatic safety clutch. Always

operate blade at high speed when edging. To

prevent damage to edger body, untangle and

remove any grass, vines or wire that may wrap

around the blade drum.

FIG 22

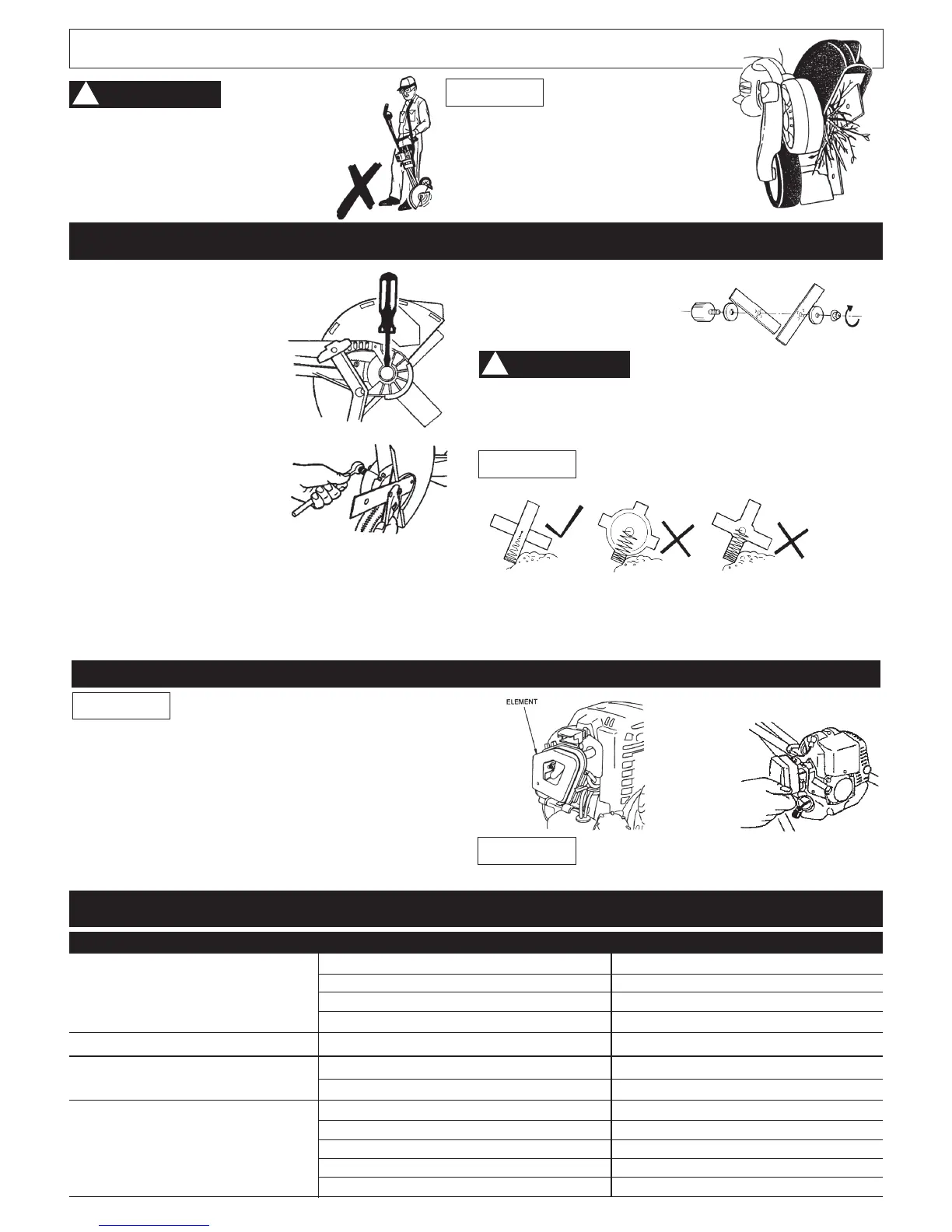

To avoid personal injury,

never carry the Edger

while the motor is running. Never hold the handle

cross brace if the motor is running. (Fig.22)

Stop the engine prior to lifting or carrying.

The Lawn Edger can be transported by

guiding it on its wheel, or carrying it with

motor switched off holding handle between

blade cover and motor.

! WARNING

FIG 26

FIT BLADES AT RIGHT ANGLES

2 SPIGOTS ON EACH BLADE

FIT INTO HOLES OF OTHER BLADE

BLADE REPLACEMENT

1. Use impact driver to undo blade

nut, then proceed to instruction 4.

Otherwise clean area around

dust cover #62936 and pry

off with screwdriver (Fig. 24)

exposing 14mm hex head (for

unscrewing blade nut).

2. Through dust cover hole, place

14MM FULL 6 SIDED 6

pointed socket spanner (do

not use 12 sided 12 pointed

socket spanner) over hex head,

and use 19mm (or adjustable)

spanner on blade nut.(Fig. 25).

3. Unscrew blade nut counter

(anti) clockwise (normal right hand thread).

4. Remove nut, one large washer and two blades (Fig. 26).

Before installing blade and washers, clean off all grit and

grease. Re-assemble these parts clean and dry. Fit large

washer, new blades #43105 with spiggots of one blade

interlocking with holes on opposite blade, large washer

and nut. Tighten nut to 15-20ft.lbs. (20-27Nm) or hand

tight with 8” (200mm) or longer spanner.

Hardened Atom spring

steel cross blades

absorb shock when

rocks and hard objects

are hit, ensuring long

edger life.

Non-Atom edger blades do not absorb

shock due to solid stiff construction.

Gear and edger life is reduced. NO

WARRANTY allowed if damage to

Atom unit caused by use of non genuine

Atom parts.

FIG 25

FIG 24

FITTING INSTRUCTIONS

USE ONLY ORIGINAL ATOM BLADES

#43105. Other blades have larger size

holes (1/2”) which will cause out-of-balance vibrations which will

damage unit and cause injury. Other blades can also break and

cause major injury. Circular blades must not be used. Only use

ORIGINAL Atom blades otherwise warranty is VOIDED.

! WARNING

Always use two blades as shown above. Never

use a single blade. Do not use other thicker

blades as you will damage the unit.

! NOTE

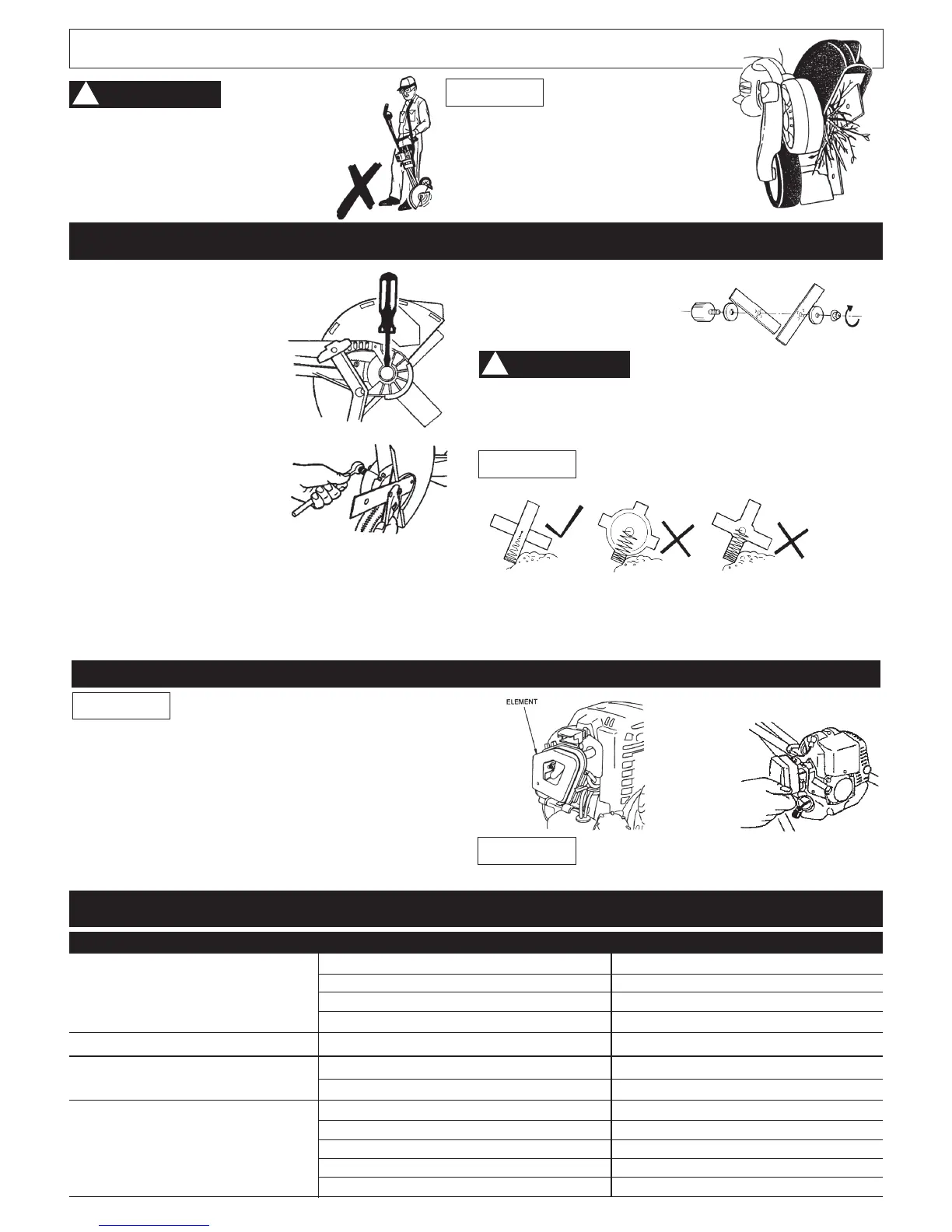

AIR AND FUEL FILTER MAINTENANCE

! NOTE

Clean and re-oil the air filter every

five hours of operation or daily.

1. The air filter (Fig.28) is one of the most important areas

to maintain. If it is not maintained, you will void the

warranty. Before cleaning, make sure the unit is turned off.

2. If filter torn or dirty replace.

3. Wash the filter in detergent and water. Rinse the filter

thoroughly and allow it to dry.

4. Apply enough clean SAE 30 or 2-stroke oil to saturate

the filter when squeezed. Squeeze the filter to spread the

oil and to remove excess oil. Re-install the filter element.

5. Replace fuel lines every 3 years, sooner if damaged.

If the unit is operated with dry or dirty filter or without

the air filter and/or carburetor air filter cover, you will

void the warranty.

! NOTE

AIR FILTER

FIG 27

FUEL FILTER

FIG 28

The fuel filter can be cleaned by hooking

out with a piece of wire and blowing with

compressed air

FIG 23

Note: Models 560 and 580 do not have

jets to adjust carburettor. CLEAN

CARBURETTOR THOROUGHLY.

Loading...

Loading...