24

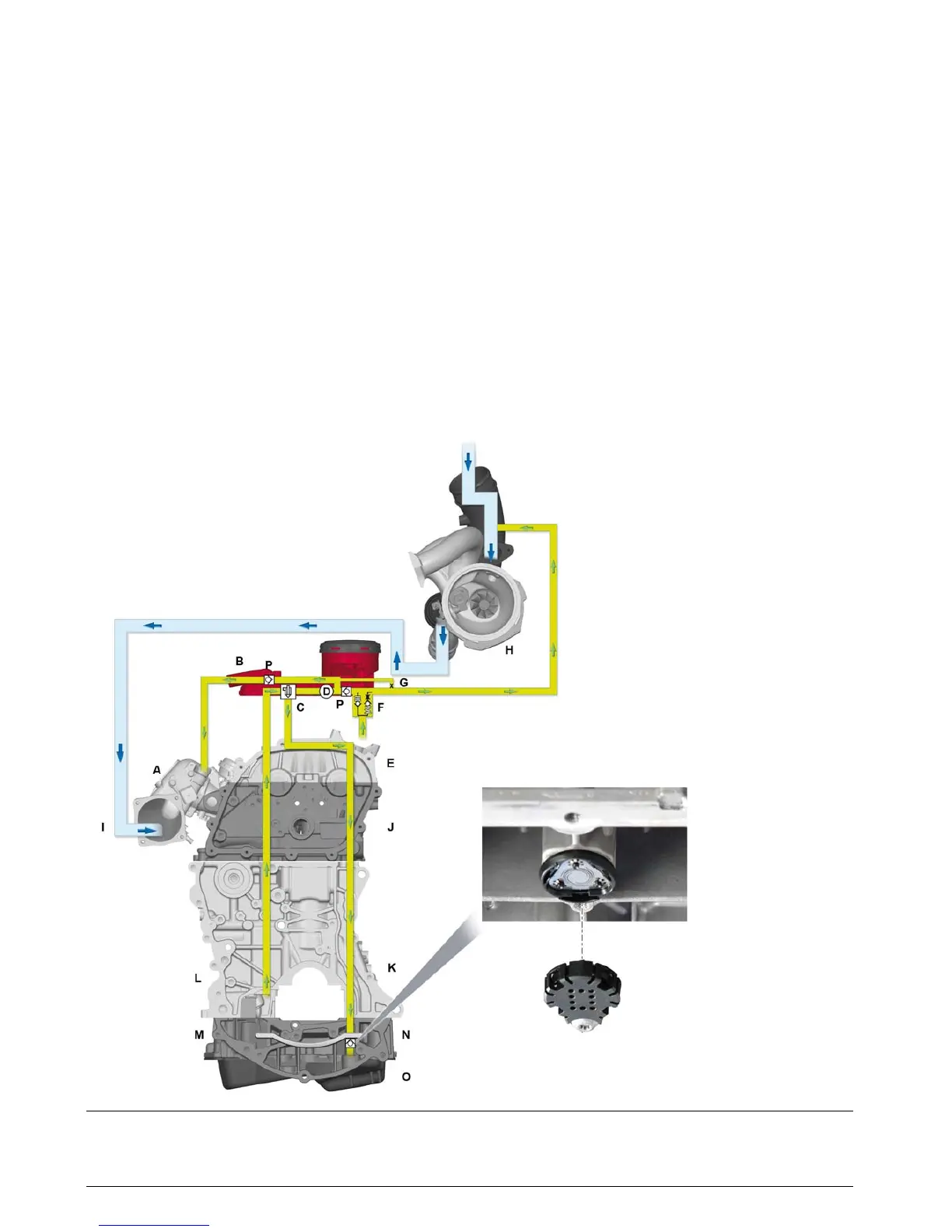

Positive crankcase ventilation system

The engine has a PCV* system for purging the crankcase with fresh

air at part throttle. This system helps to separate the fuel and

water which usually become entrained in the oil in the combustion

process during engine operation. If fuel and water are allowed to

remain in the oil sump, they can ice up at low ambient tempera-

tures and damage the ventilation system and the engine (e.g. loss

of oil pressure due to ice sludge clogging up the oil intake snorkel,

oil leaks due to excess pressure in the engine).

By admitting ambient air extracted downstream of the air filter,

the fuel and water are channelled through the rocker cover and

into the cylinder head. The dry fresh air then flows through the

chain shaft and into the crankcase, absorbing moisture and fuel

along the way, thereby "flushing" the engine dry.

This useful life of the oil is greatly prolonged by this measure, as

it slows down the ageing process.

The fresh air for crankcase ventilation is extracted from the posi-

tive crankcase ventilation line running to the exhaust turbo-

charger.

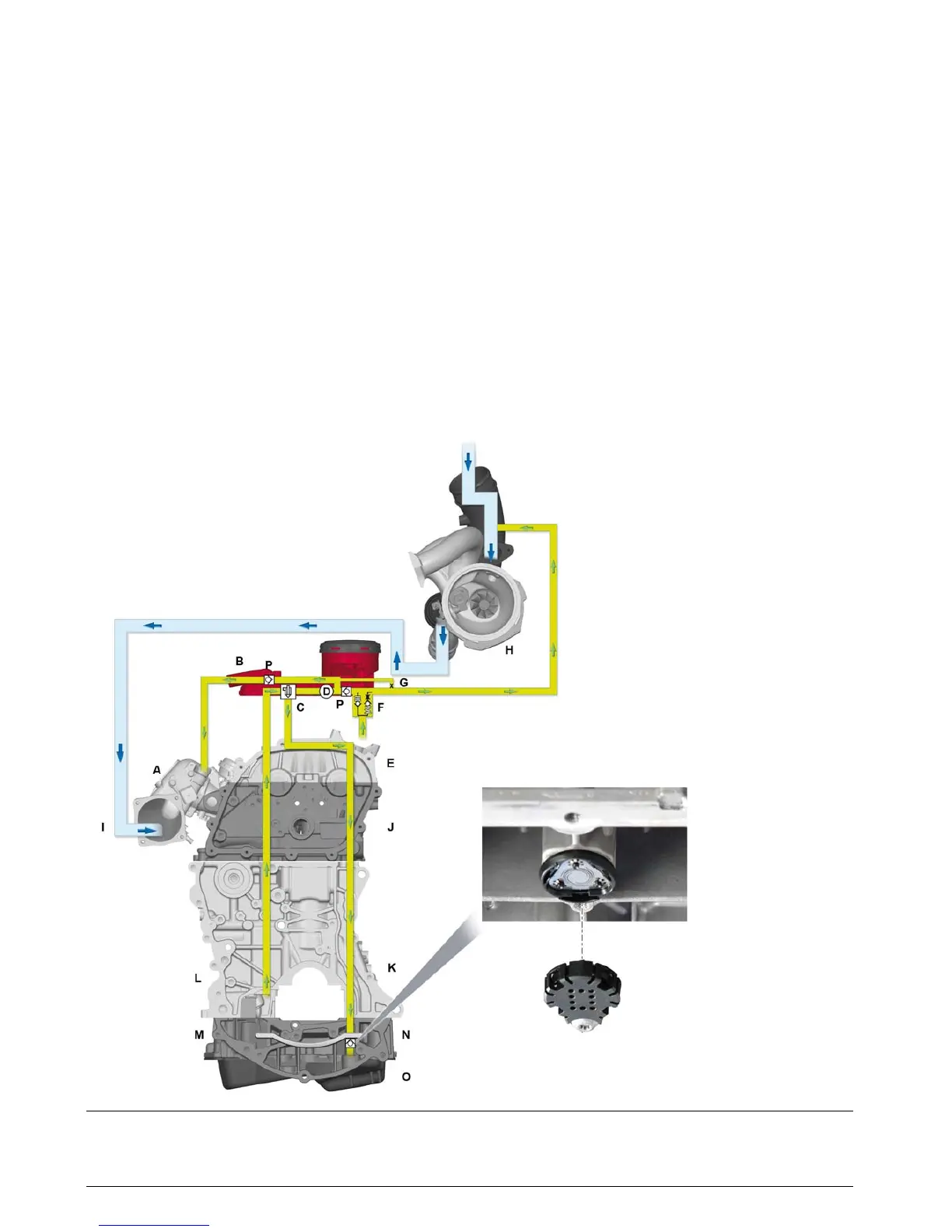

The PCV valve, a combi valve, is integrated in the rocker cover.

This valve has the following tasks:

• If a slight partial vacuum is present in the crankcase during

normal operation, it opens in order to vent the crankcase. Fresh

air flows from the line downstream of the air filter and into the

engine.

• If a pressure of over 100 millibars develops in the engine, the

excess pressure is relieved into the line, thereby protecting the

crankcase seals.

Furthermore, all Audi systems are still designed in such a way that

non-installation or faulty installation is diagnosable. If one of the

two crankcase ventilation lines is not installed, the unmetered air

is diagnosed via the lambda control system and indicated to the

driver by lighting-up of the MIL lamp.

451_040

Note

All components required for cleaning and ventilation are integrated in the rocker cover. If one of these components fails,

the complete rocker cover has to be replaced.

Loading...

Loading...