6

5

injectors and real-time monitoring of the dynamic values.

Automatic fuel draining through preset programs for some

test items. Test liquid/detergent can also be drained by

pushing a button on the control panel after the test.

Adopting humanization design can make the system pressure

fast restored to the default values.

Input power: 250W

Timing range: 1 to 9999 seconds

Pulse width range: 0.5 ~ 25ms Step size 0.1ms

Specifications

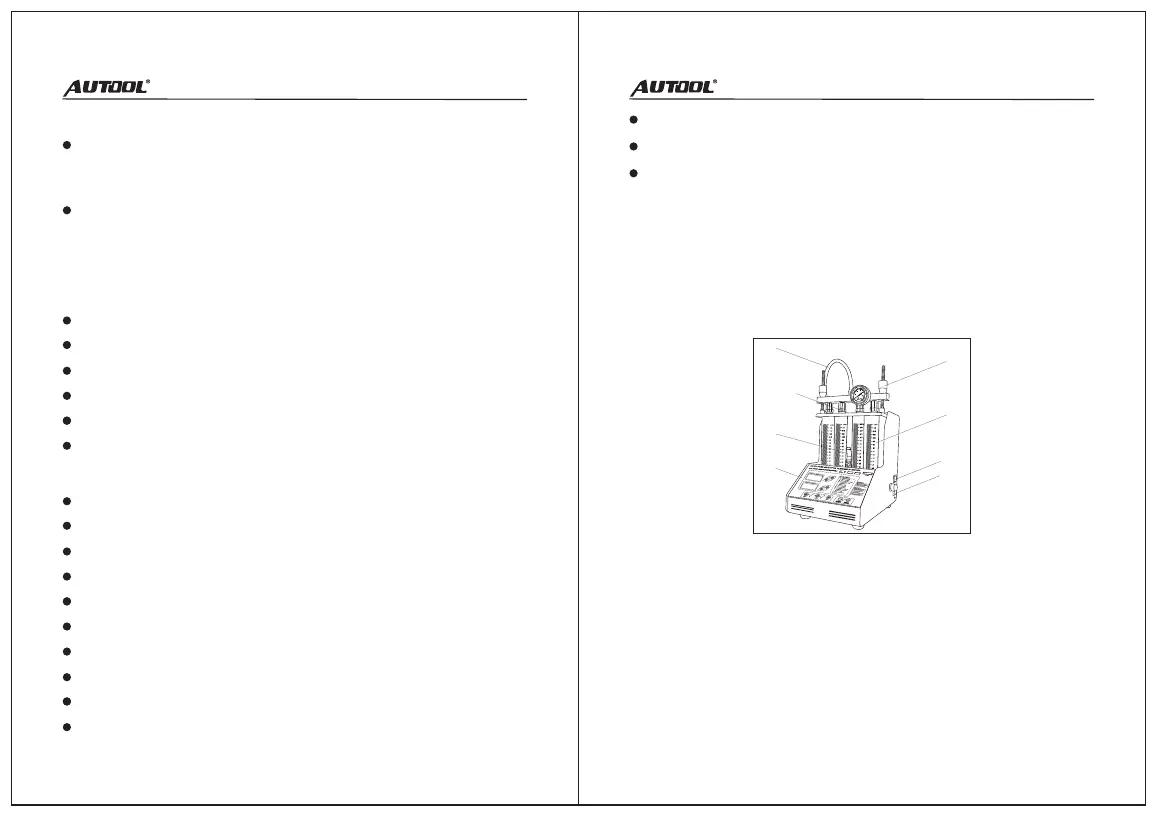

The CT150 injector cleaning detector is a cabinet structure.

CT150 is similar to C150 except the number of the tanks. The

Figure 1 shows the structure of the CT150. It is divided into two

layers. The upper layer is the ultrasonic cleaning machine table

and the lower layer is the control panel console.

Power supply: AC220V±10%

Frequency: 50HZ±0.5

Ambient temperature; -10 °C ~ +40 °C

Relative humidity: <85%

External magnetic field strength: <400A/m

Open flames are strictly prohibited within 2m

Working Condition:

Power supply: AC220V/AC110V±10% 50Hz/60Hz

Fuel Tank Capacity: 2000 ml

Capacity of Measuring Cylinder: 125 ml

Speed Range: 0~7500 rpm

Injecting Times: 0~9900 Step: 100ms

PWM Pulse: 0~20.0 ms Step: 0.1 ms

System Pressure: 0~0.6Mpa (adjustable)

Time: 0~20 minute (adjustable)

Power of Ultrasonic Cleaning: 70W

Frequency of Ultrasonic Cleaning: 28 KHZ±0.5 KHZ

Working Condition:

Structure

1-quick-connect tubing;

4-control panel (console); 5-fixing bolt; 6-test tube; 7-power

switch; 8-power outlet;

2-ultrasonic cleaner; 3-level switch;

Control Panel

The control panel is shown in Fig.02.(The panel of CT150

and CT200 are similar.)

Figure.01

1

2

3

4

5

6

7

8

Loading...

Loading...