Page 4

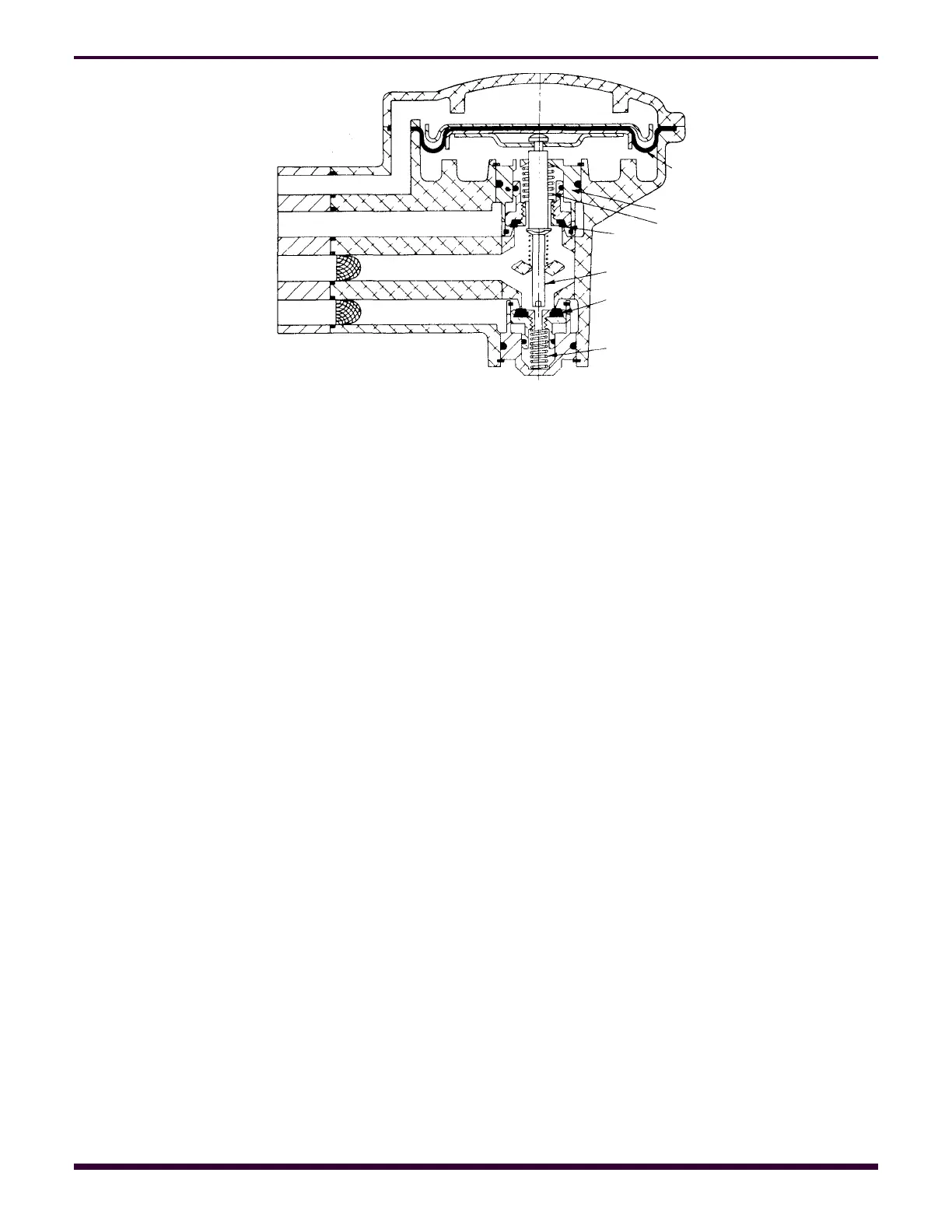

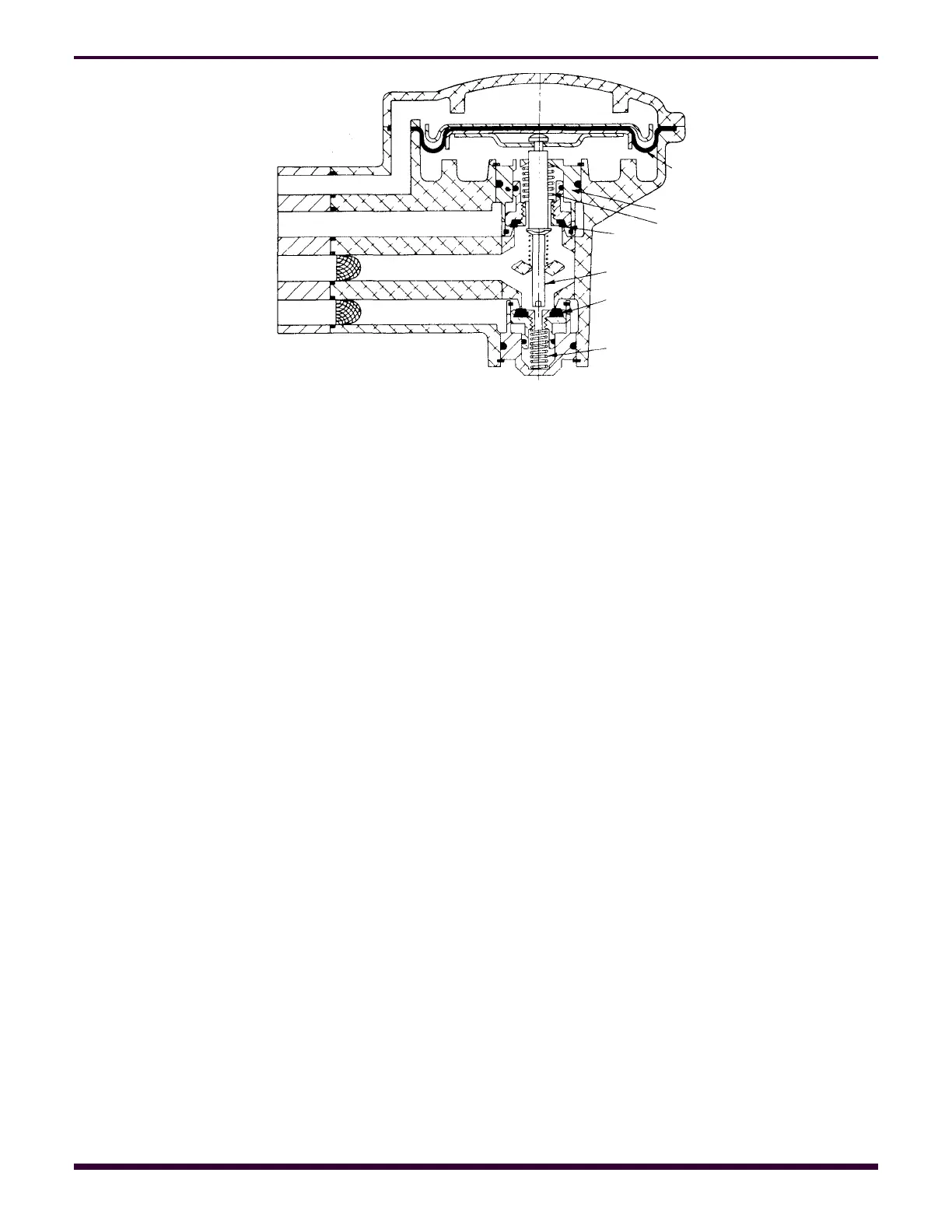

Referring to Figure 4, with supply air

pressure present in port 1 and no air pressure

present on the control diaphragm 36, both the

supply valve 7 and the exhaust valve 24 will be

seated by their respective springs. Assume that

air pressure is admitted to the control port 2 of

the valve. This pressure will be delivered to the

upper side of diaphragm 36 causing it to move

downward, carrying diaphragm stem 20 with it.

During this movement, the diaphragm stem will

contact the differential type supply valve 7 and

unseat it by compression of spring 5. Supply air

from port 1 will then flow past the unseated

valve to the delivery port 3 where it is piped to

the device being operated. Supply air also flows

through the choke in the exhaust valve cage 22

to the underside of the control diaphragm 36.

When the pressure under the diaphragm is

substantially equal to the control pressure on top

of the diaphragm, the diaphragm assembly will

move back toward its initial position and the

supply valve will seal, aided by spring 5, thus

cutting off further flow of supply air to the

delivery port.

The relay valve will maintain this delivery

pressure against leakage. In the case of a

reduction in delivery pressure, the higher

pressure on the upper side of the diaphragm will

cause movement downward repeating the

application cycle and restoring the delivery

pressure to the desired value.

When the control pressure to the valve is

reduced, the higher pressure on the

underside of the diaphragm 36 will cause it to

move upward carrying stem 20 with it. During

this movement, a shoulder on the diaphragm

stem will contact the differential type exhaust

valve 24 and unseat it by compression of

spring 27. Air from the delivery port will then

flow past the unseated exhaust valve to

atmosphere reducing the pressure in the

device being operated. When this pressure

has been reduced to balance the pressures

on diaphragm 36, the diaphragm assembly

will move back toward its initial position and

the exhaust valve will seal aided by spring 27,

thus cutting off the flow of air to exhaust. If the

control pressure is completely removed from

the diaphragm, the valve will completely

e x h a u s t t h e d e l i v e r y p r e s s u r e .

During an application of air to an

operating device, if the pressure in the

delivery line should increase due to

temperature variation or other causes, this

condition will unbalance the diaphragm to

repeat the exhaust cycle described above

until the desired pressure is again reached.

From the foregoing it will be seen that the

C-2 Relay Valve will reproduce in the delivery

line a pressure equal to that in the control line

and will maintain this pressure against

leakage or temperature effect.

Fig. 4. Diagrammatic View

22

36

27

24

20

7

5

CONTROL———-2

EXHAUST ———EX

DELIVERY ———3

SUPPLY ——–—-1

Loading...

Loading...