27

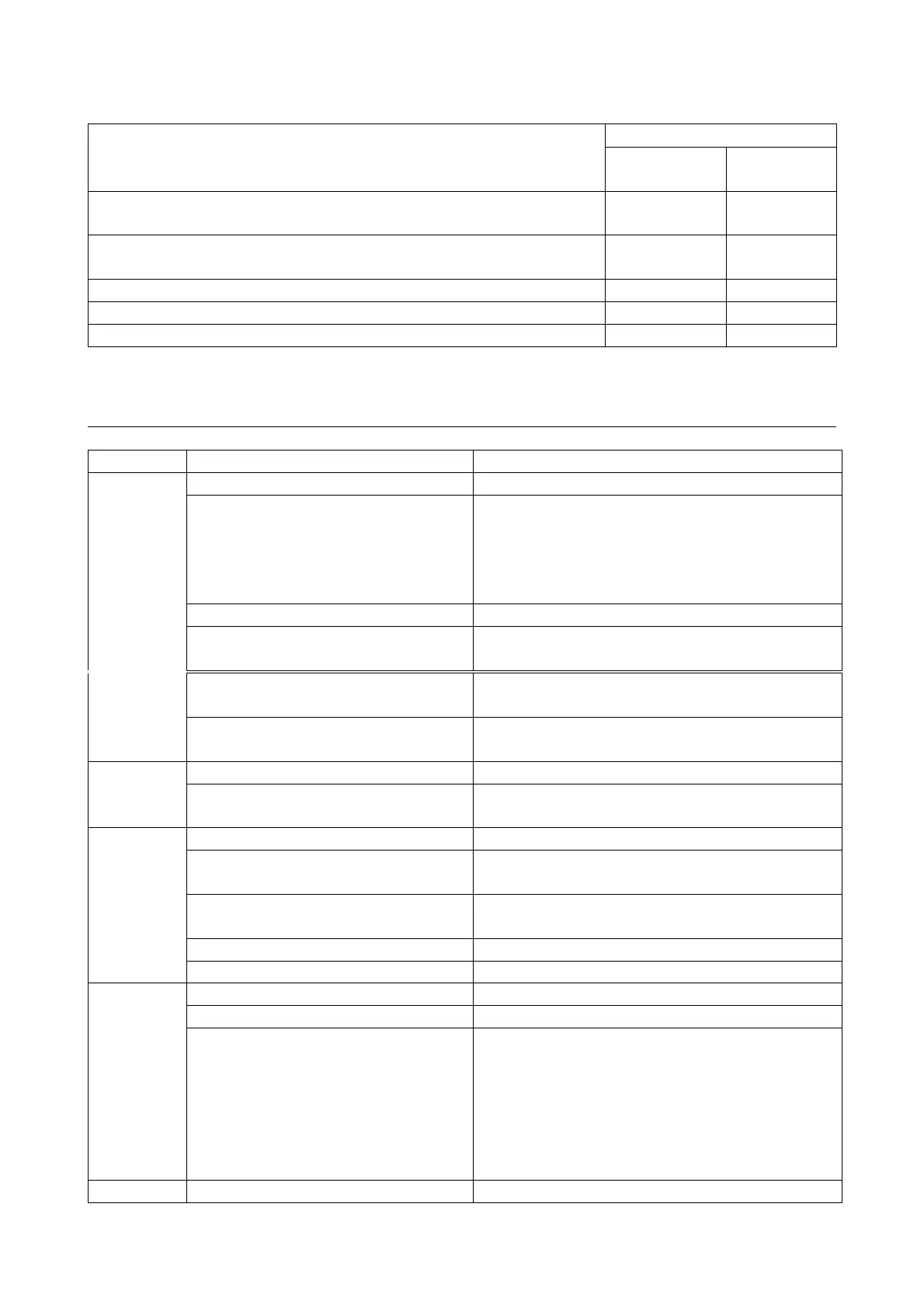

Object of inspection Inspection interval

Daily Every 3

months

Check the condition and sufficient tightening of the attach-

ment bolts.

x

Check the condition of the wire (abrasions, broken strands,

rust)

x

Check the condition of the motor (oxidations, damages) x

Check the condition of the brake and its faultless operation x

Check the condition of the gears (abrasions, damages) x

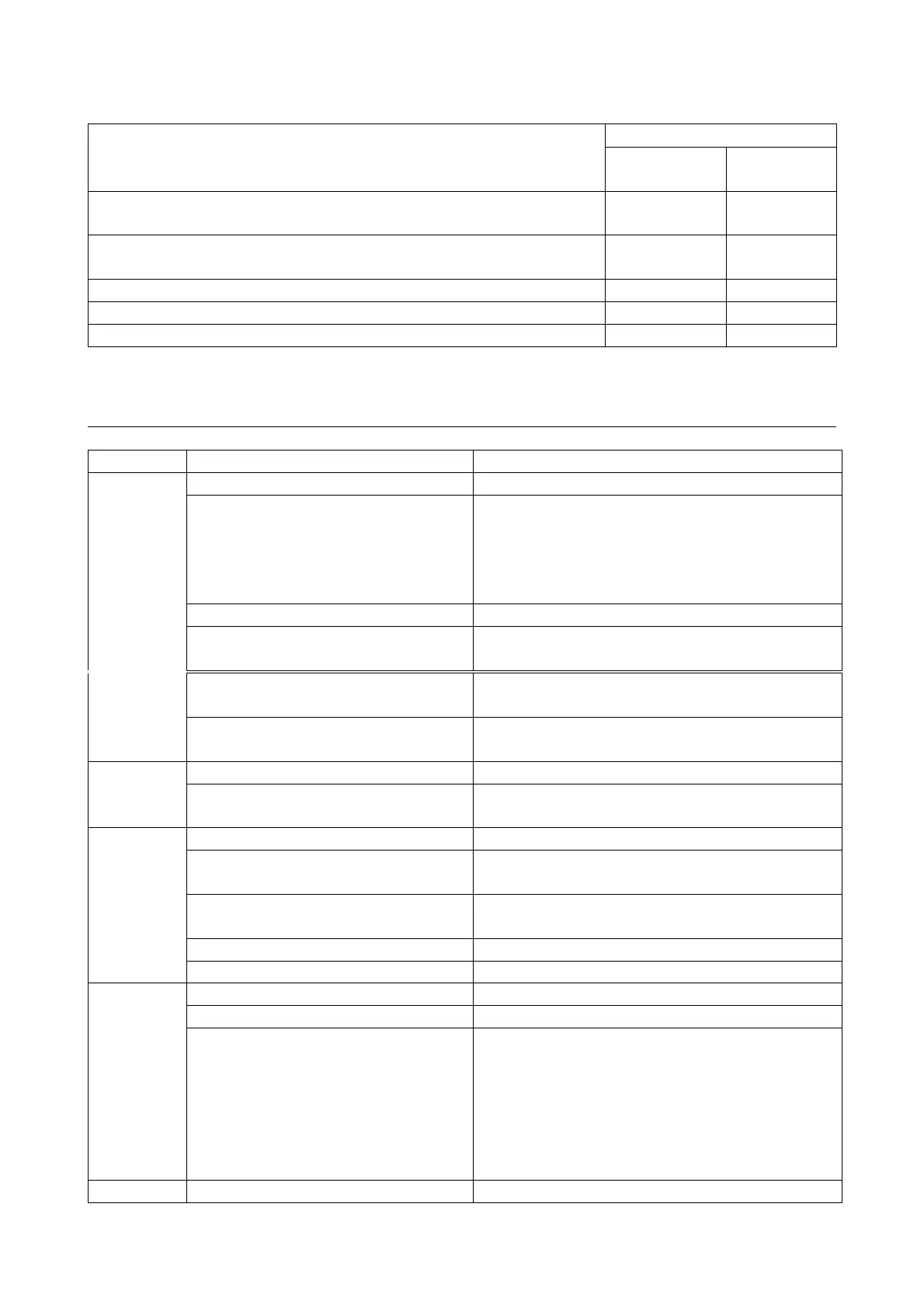

TROUBLESHOOTING

Problem Cause Solution

Hoist will

not oper-

ate.

Loss of power. Have checked by a professional electrician.

Wrong voltage or frequency.

Check that the voltage and frequency of

power supply correspond with those

marked on the motor rating label. Have re-

paired by a professional electrician, if nec-

essary.

Overload. Reduce load to within rated capacity.

Improper, loose or broken wire in

the electrical system.

Have checked by a professional electrician.

Blown fuses.

Check fuses and have repaired by a profes-

sional electrician, if necessary.

Burned motor.

Have motor replaced by an authorized ser-

vice center.

Hoist lifts

but will

not lower.

Faulty switch in control unit. Have checked by a professional electrician.

Broken conductor in control unit

cable.

Have checked by a professional electrician.

Hoist low-

ers but will

not lift.

Overload. Reduce load to within rated capacity.

Worn friction clutch.

Have repaired by an authorized service cen-

ter.

Broken conductor in control unit

cable.

Have checked by a professional electrician.

Faulty switch in control unit. Have checked by a professional electrician.

Low voltage in power supply. Have checked by a professional electrician.

Hoist will

not lift

rated load

or does

not have

the proper

lifting

speed.

Overload. Reduce load to within rated capacity.

Low voltage in power supply. Have checked by a professional electrician.

Faulty friction clutch.

If unusual operation or slippage occurs, do

NOT attempt to disassemble or adjust the

mechanical load brake or friction clutch.

Have worn or malfunctioning mechanical

load brake with friction clutch replaced as

an assembly with a new factory part by an

authorized service center.

Load drifts Demagnetized motor. Motor demagnetizing is generally caused

Loading...

Loading...