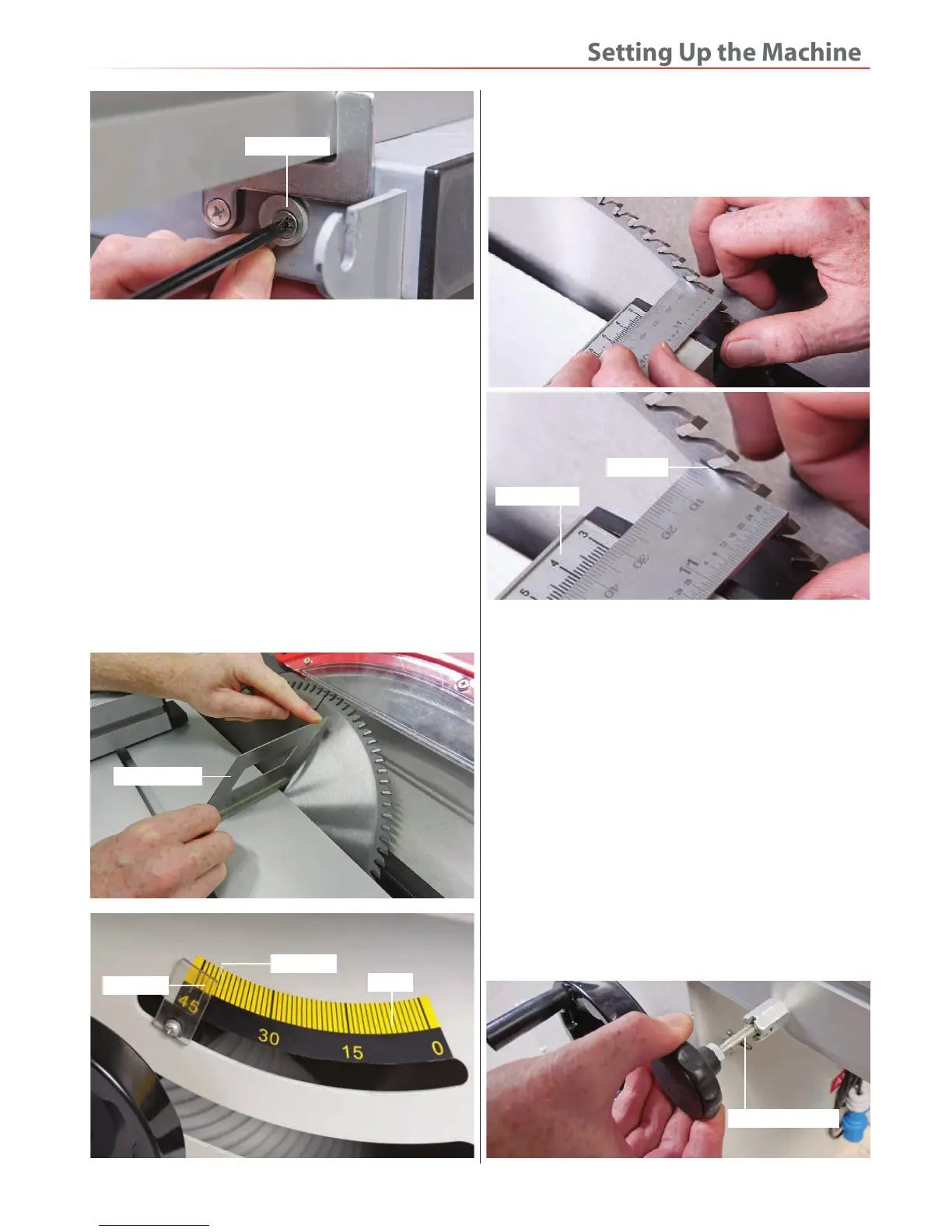

Fig 101-102

Saw tip

Fence scale

4. Using a steel rule measure 30mm back from the saw

tip, so the scale on the rule lines up with the 30mm on

the fence scale (23), see fig 101-102. Secure the fence

again as described in step 1.

Sliding Table

There should be (0.5 to 2mm) clearance between the

main saw table (0) and the sliding table (19) to allow the

blade to turn freely without it snagging.

1. Raise the saw to it’s highest point and lock the sliding

table (19) in position with the locking pin knob (G), see

fig 103.

2. Using a feeler gauge, loosen the two upper locking

nuts on the mounting bolts below the sliding table (19),

see fig 104 slot the feeler gauge down the gap between

the two tables from one side and adjust until the gap is

set between (0.5 to 2mm), repeat the procedure for the

opposite side, see fig 105.

Table Clearance

Fig 103

Locking pin knob

2. Slide the nose of the fence (the black tongue) up to the

blade, check the parallelity of the sliding table movement

by sliding the table forward and checking the tongue/

blade are still in contact, or that the movement has not

jammed the tongue against the saw. If there is a slight

discrepancy, it may be acceptable to you (a 1mm

difference across the face of the blade (fully extended)

is about one quarter of a degree).

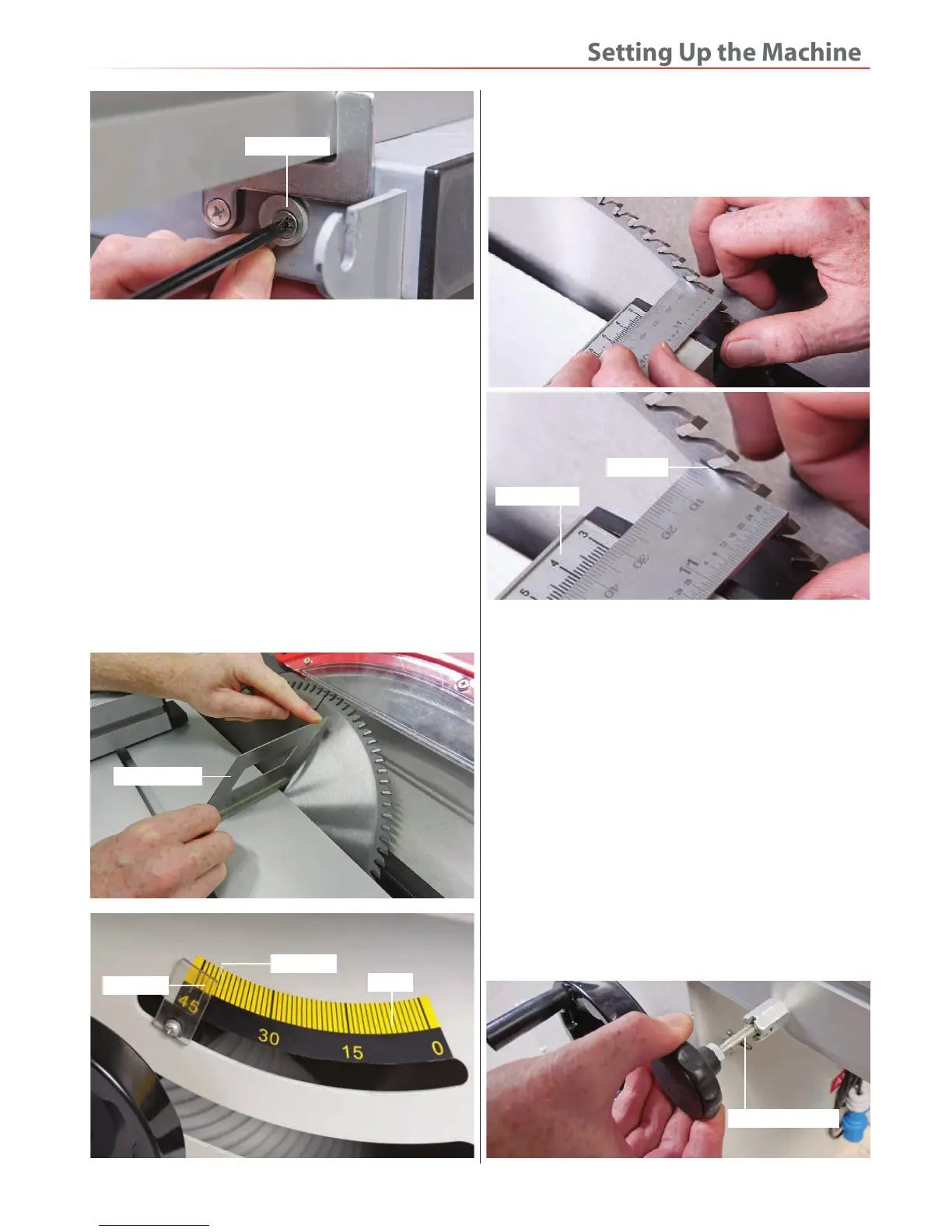

3. Tilt the blade fully over. Using a mitre square, set the

angle of the saw to 45˚degrees. Check that the index

mark gives a corresponding reading against the scale,

see fig 99-100. Adjust the pointer if necessary. Reset the

blade upright, check that the angle scale reading is

correct.

90˚ Stop cam

Fig 99-100

Mitre square

Pointer

Scale

Index mark

Loading...

Loading...