9

Continues Over....

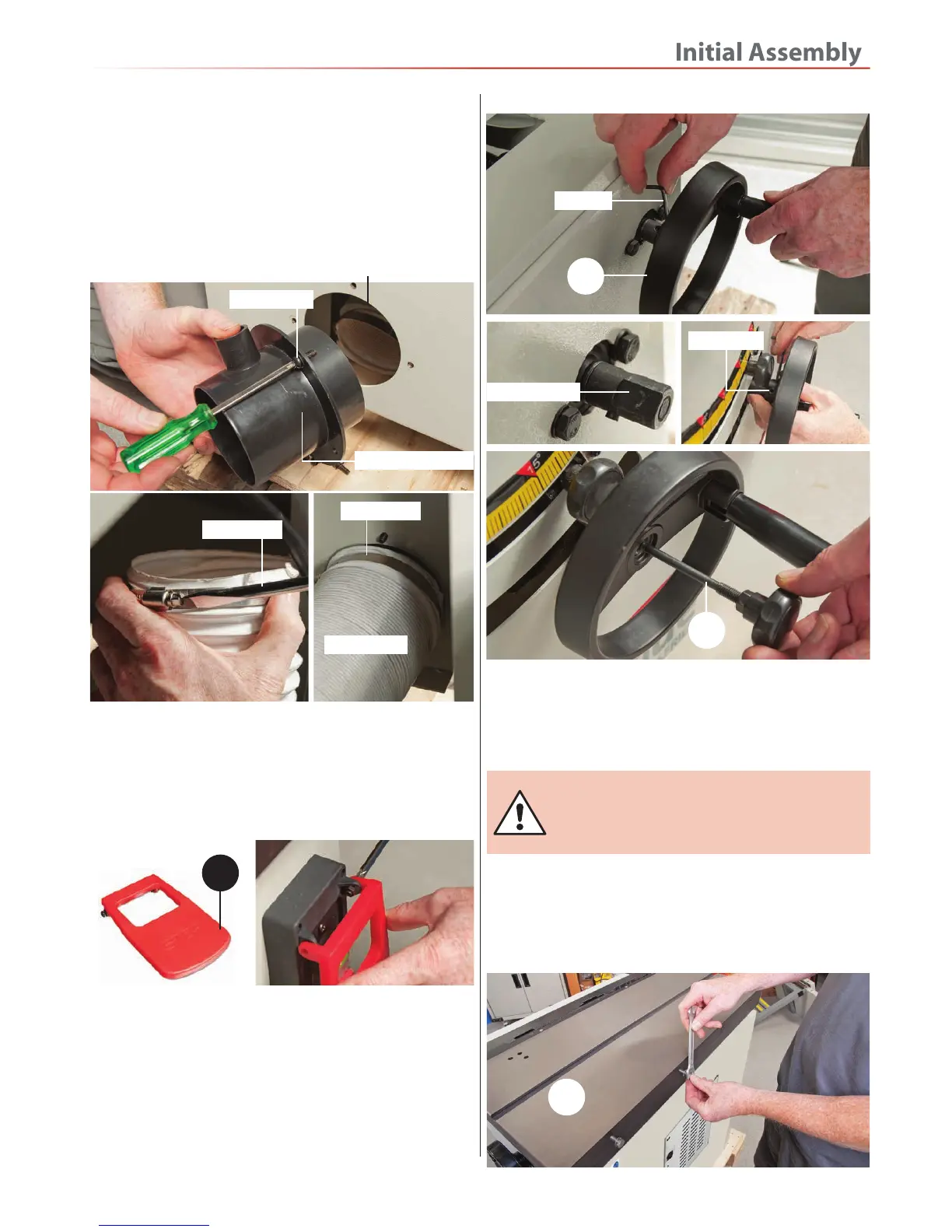

moulding (16) into the round machined cut-out, line up

the pre-drilled holes and secure in place with the fixings

you removed earlier, see figs 01.

2. Open up the side access door and place a hose clip

over the end of the flexible hose, insert the end of the

hose over the extraction moulding and secure in

position, see fig 02-03.

Fig 01-02-03

Extraction moulding

Phillips screw

Flexible hose

Machined cut-out

Hose clamp

Screwdriver

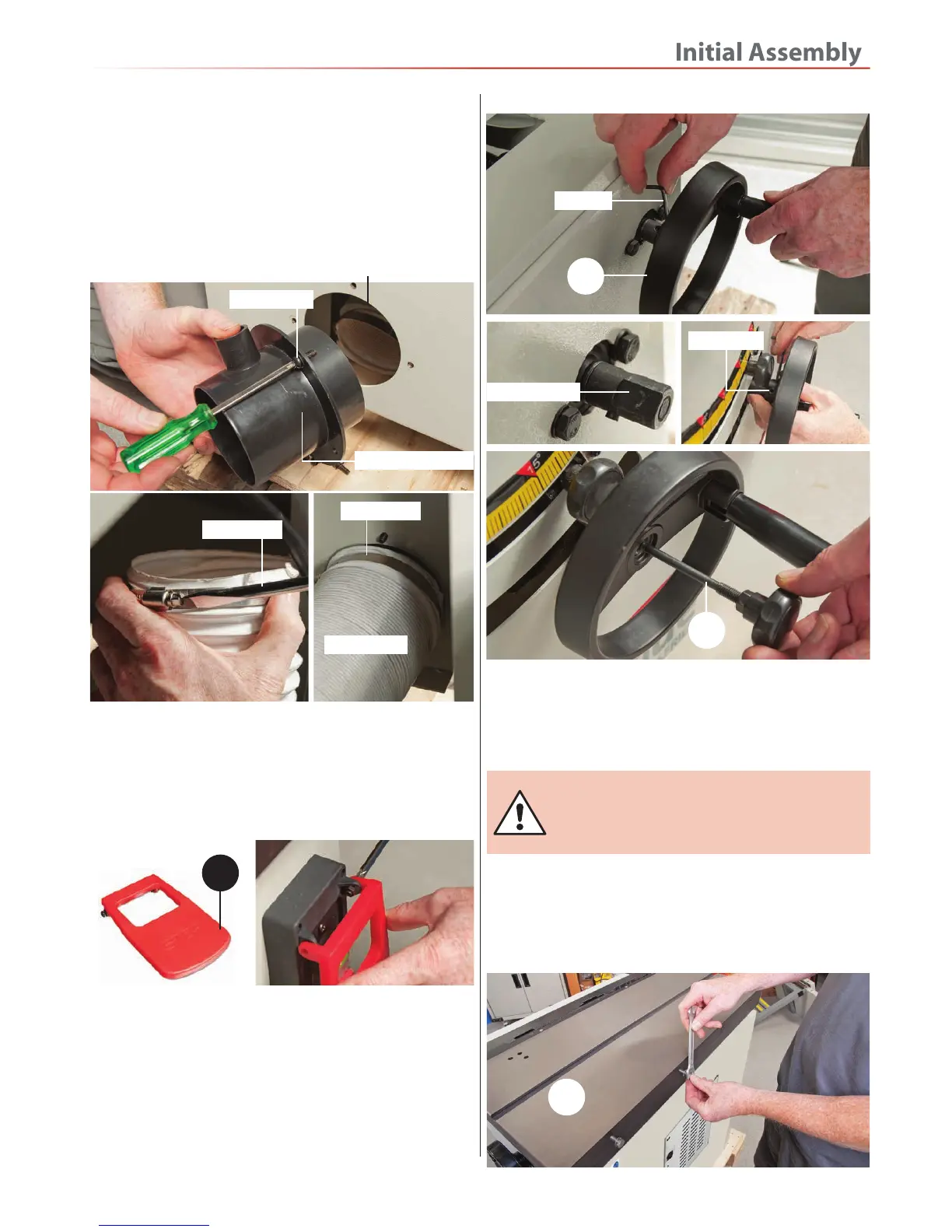

4. Locate the hand wheels (15). Undo the grub screw

with the supplied Hex key to one of the hand wheels

(15), slide the wheel onto the drive shaft and re-tighten

the grub screw. Repeat for the remaining operating

wheel, see figs 06-07-08. DO NOT OVERTIGHTEN

NOTE: Make sure you line up the grub screw with

the machined surface on the drive shaft.

Fig 06-07-08-09

Hex key

15

Machined face

Right Hand Extension Tables

Rise/Full and 45˚ Operating Wheels

WARNING!! THE CAST IRON EXTENSION

TABLE IS VERY HEAVY YOU WILL REQUIRE

A SECOND PERSON TO HELP!

1. Locate the two extension tables (10-11) and the right

hand table support leg assembly (8). Remove the four

M8x25mm bolts and washers from the side of the saw’s

main table (0) and place safely aside, see fig 10.

Fig 10

0

3. Locate the RED emergency stop lever (9) and remove

the two Phillips screws and nuts. Line up the holes in the

hingees with the ones on the NVR switch housing, insert

the Phillips screws through the hingees and replace the

nuts. Lightly tighten sufficiently to allow the lever to

move freely, see fig 04-05.

Fig 04-05

9

Grub screw

5. Locate the locking pin knob (F) and screw locking

knob through the centre of the rise and full operating

wheel, see fig 09.

F

Loading...

Loading...