Introduction

v

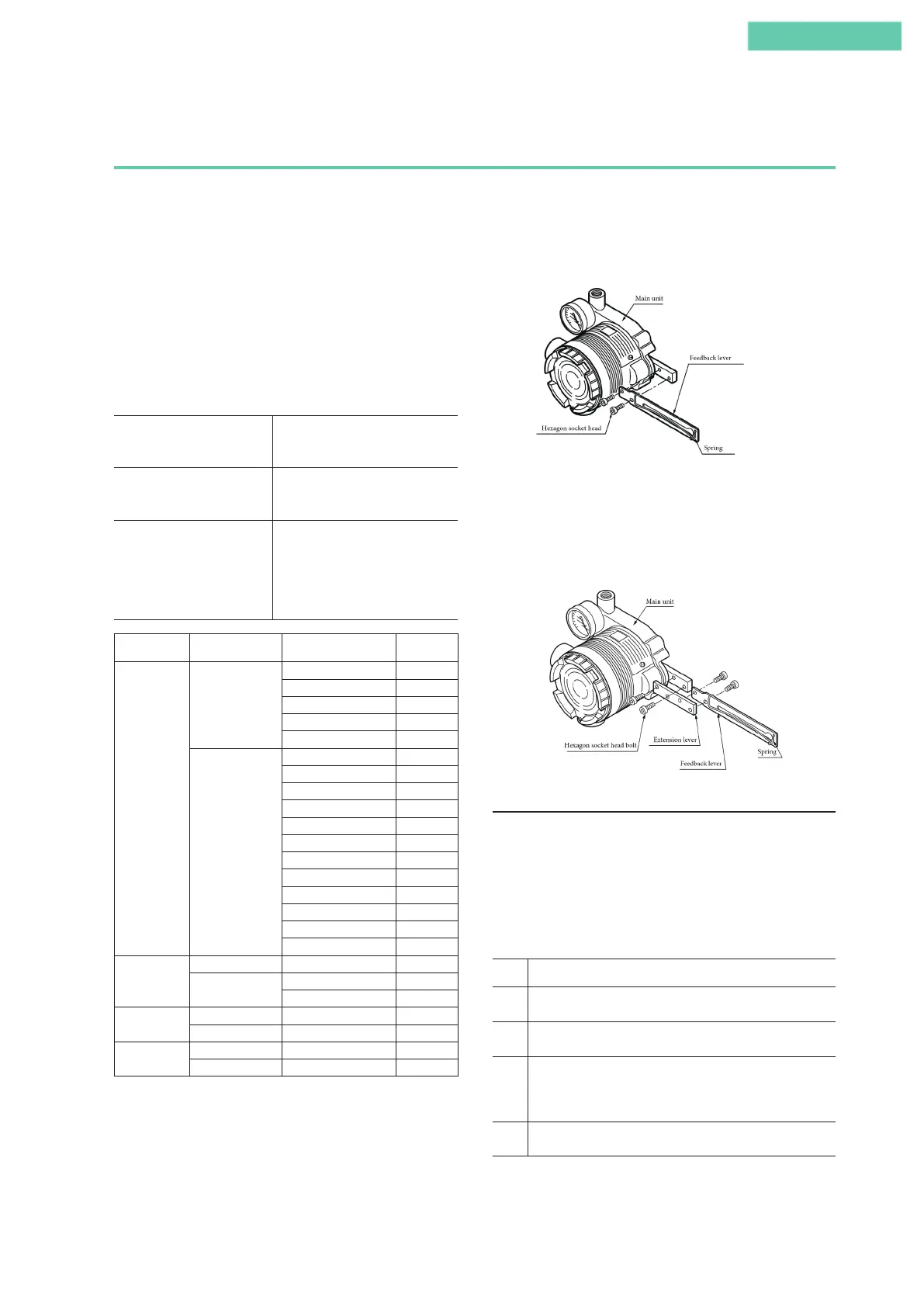

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the pack-

aging as well, the feedback lever is detached from the body of

the device when it is packed. As a result, the feedback lever

must be attached to the body of the device prior to installa-

tion of the device.

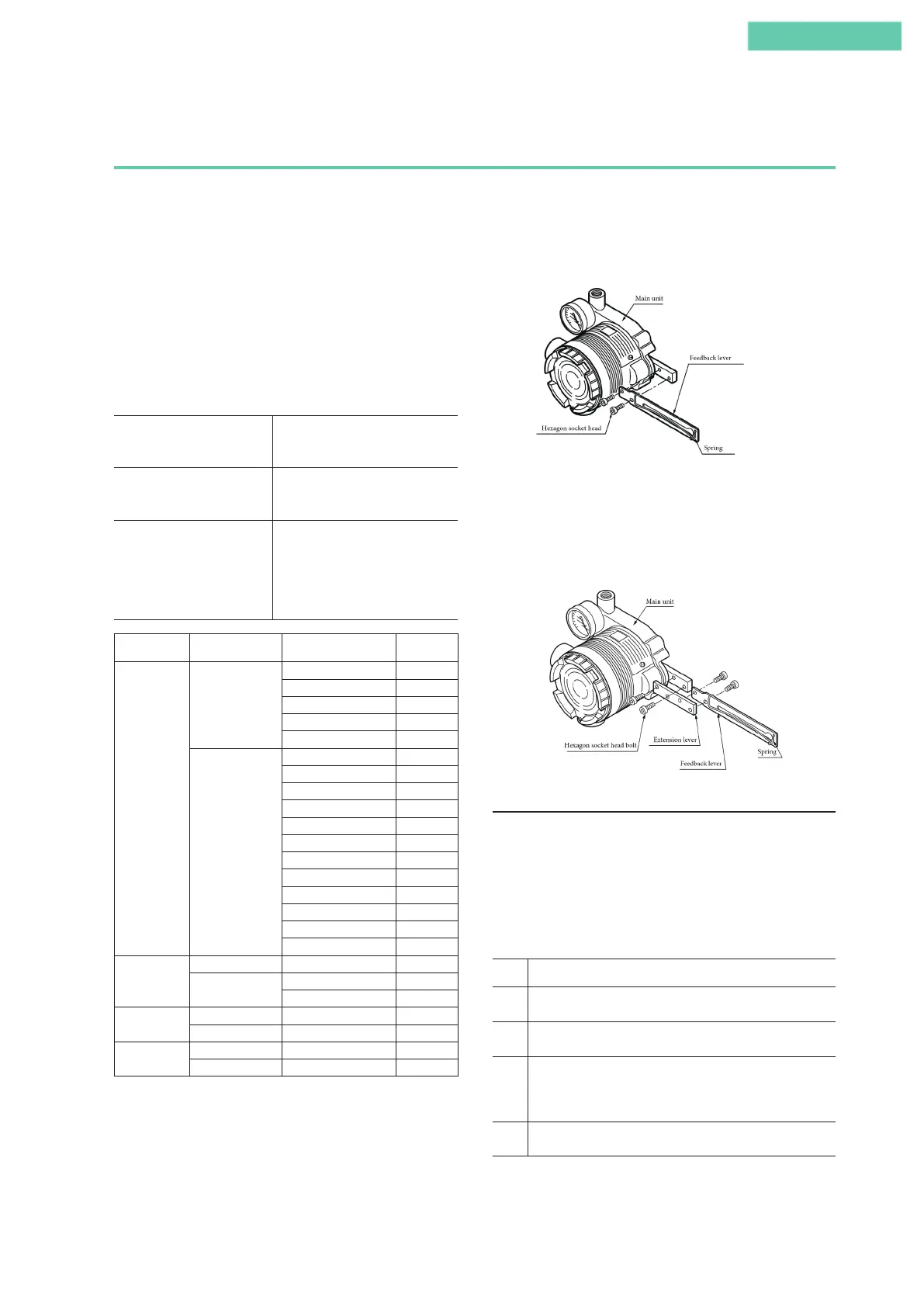

The length of the feedback lever can if necessary be adjusted

by attaching the extension lever between the feedback lever

and the body of the device. Adjustment of the feedback lever

length is determined based on the form of the actuator.

If the actuator type is specified

when ordering, and the

extension lever is included:

Attach the extension lever to the

body of the device, and then attach

the feedback lever.

If the actuator type is specified

when ordering, and the

extension lever is not included:

The extension lever is not necessary.

Attach the feedback lever directly to

the body of the device.

If the actuator type is not

specified when ordering:

The extension lever will be

included. Refer to the table below

to determine, based on the actuator

with which the device is equipped,

whether or not the extension lever

is necessary.

Manufacturer Extension Lever Actuator Type Code

Azbil

Corporation

No

PSA1, 2, PSK1 YS

HA1 YA

HA2, 3 YT

HK1 YK

VA1 to 3 YQ

Ye s

PSA3, 4 YQ

PSA6 YL

HA4 YN

PSA7 Y8

VA4 to 6 YL

RSA1 YF

RSA2 YU

VR1 YV

VR2, 3 YR

VR3H Y6

GOM83S, 84S, 103S YG

GOM124S YM

Motoyama

No #240, #280, #330 TA, TD

Ye s

#400, #500S, #500L TB, TE

#650S, #650L TC, TF

Masoneilan

No #11, #13 MA, MB

Ye s #15, #18 MC, MF

Nihon Koso

No #270, #320 TA, TD

Ye s #400, #500 TB, TE

When connecting an actuator other than those in the table,

connect the device and the actuator, and then switch to

manual mode and move the actuator slowly and ensure that

the feedback lever does not interfere with the full stroke of

the actuator.

If the feedback lever alone cannot cover a full stroke, attach

the extension lever to it.

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Attachment of Feedback Lever

Attach the extension lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Then, in the same way, attach the feedback lever securely,

working from the back of the device. (The feedback lever can

be attached from the front as well.)

Attachment of Extension Lever and Feedback Lever

2. Attachment and installation

[1] Attachment to the actuator

Attach to the actuator with a mounting plate that is appropri-

ate for the actuator.

[2] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2 Supply air, and adjust the actuator air pressure such that the

actuator stem reaches the travel midpoint.

3 Adjust the actuator such that the feedback lever reaches a

90° angle to the device's central vertical axis. Depending on

the actuator being used, adjustment may be performed by

moving the device, or it may be performed by moving a pin.

4 Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ±2°.

Combination of model AVP300/301/302 (integral type) and single-acting linear

diaphragm actuator

Loading...

Loading...