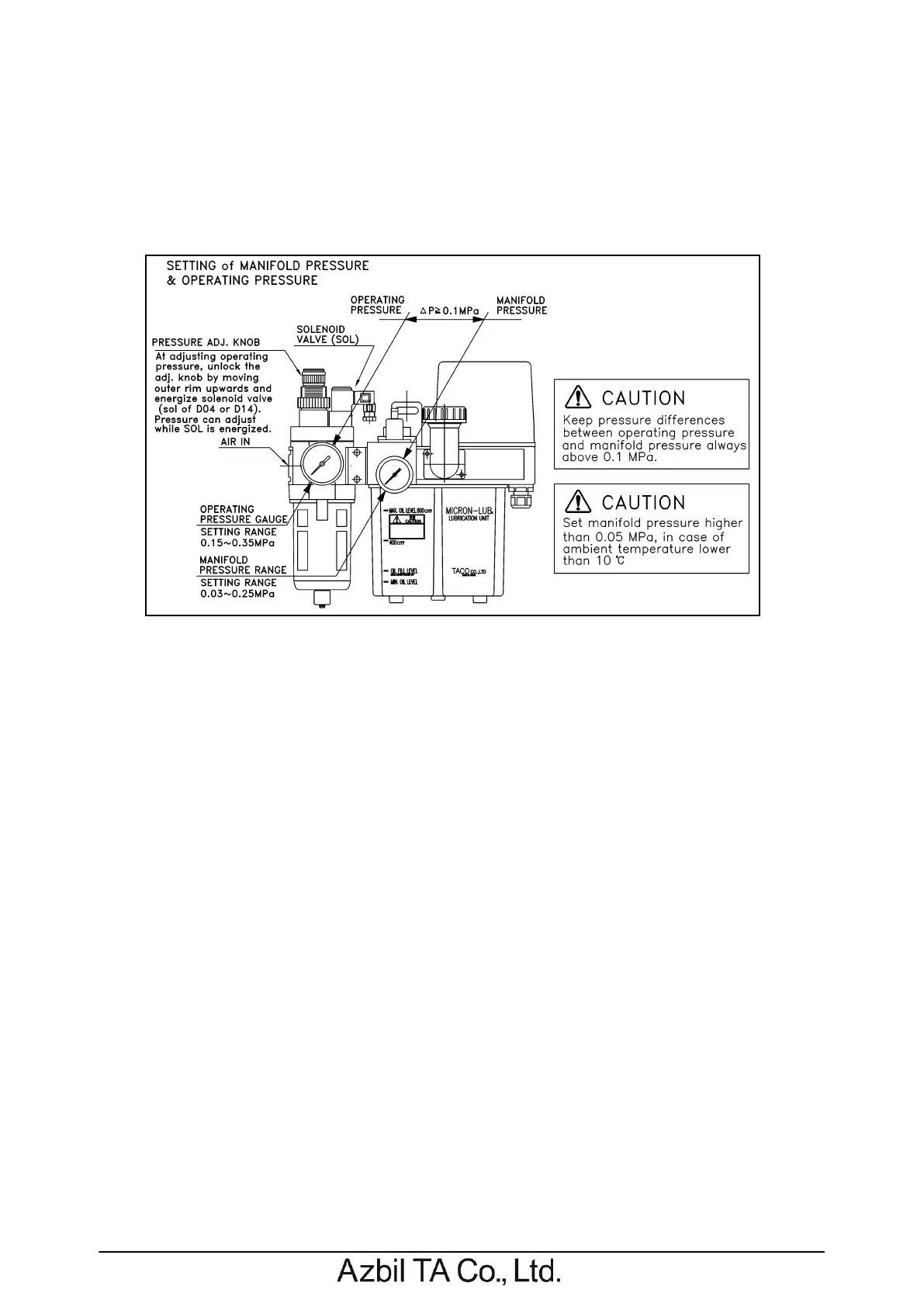

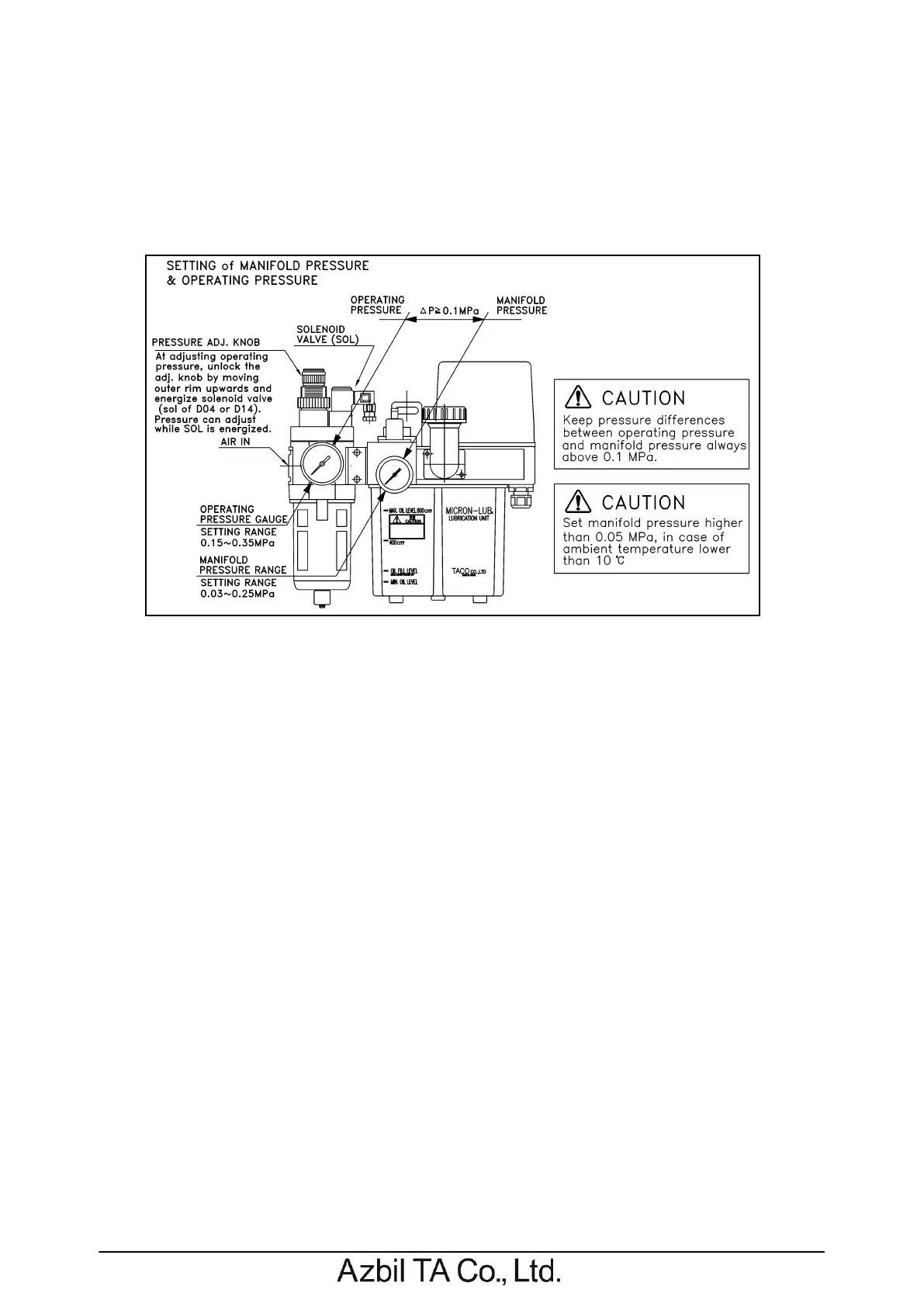

・In case of the application with ambient temperature under 10℃, set the manifold pressure higher

than 0.05MPa.

・ After adjustment of manifold pressure, confirm there is pressure difference of more than

0.1MPa between manifold pressure and operating pressure on the lubrication unit. If the

pressure differences become smaller than 0.1MPa, increase the operating air pressure. And

re-adjust the manifold pressure.

7-4. Operation of Oil-Shot Pump and Confirming of Oil Dripping

・When electric supply to the lubrication unit is switched ON, the oil shot pump starts action by

interval timer. Then oil will be drop into sight-dome through drip tube.

・If the lubrication unit is installed to the machine newly, set the operating pressure slightly higher

than pressure intended for normal operation, after by-pass air adjusting screw closed. Then

actuate the pump about 100 times with 1 or 2 seconds interval, until oil drops can be seen

certainly.

・This is to fill lubricant into oil tube from the pump to sight-dome. And this ensures oil drippings to

the sight-dome on each action of the pump.

・MC9 units equipped with Oil Monitor are possible to confirm dripping of oil or supplying of oil by

using sensor.

Loading...

Loading...