8

AB-6600

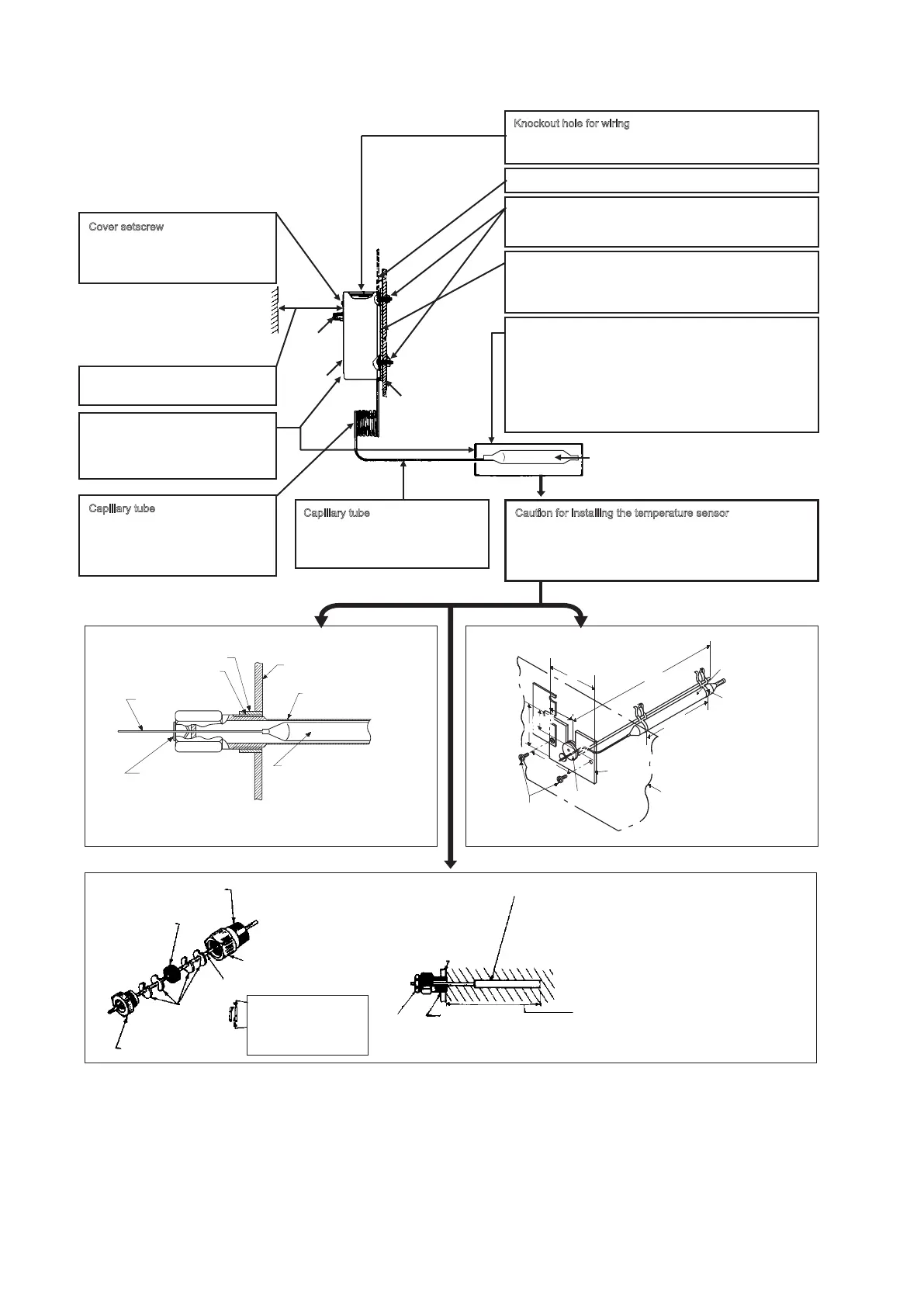

Note: If the immersion well is used, ll the well with special grease to improve response performance of the temperature sensor.

(Ex. For the stainless steel immersion well, response performance will be improved by approx. 15 %.)

For the special grease, the silicon grease, G-30M (Shin-Etsu Chemical) or equivalent, is recommended.

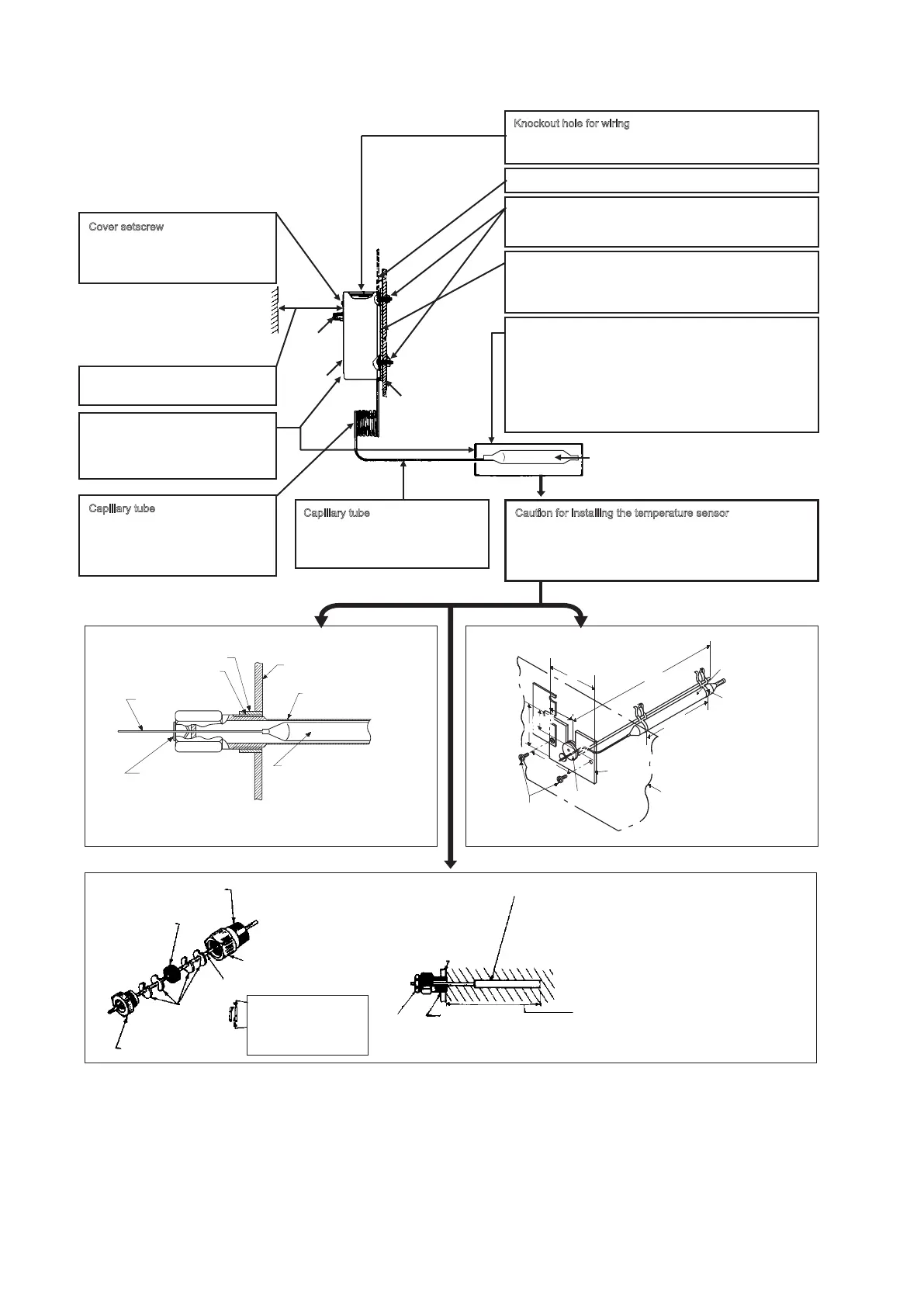

Figure 9. Installation

Pressure fitting installation

1/2NPT screw

Packing

Plug

Capillary tube

Washers

Nut

Surface of tank

(boiler)

ク

壁

83

35

83

83

83

41.541.5

356

Temperature sensor

Spring clips (x2)

Position is adjustable.

Duct

Rubber

grommet

Mounting screws (x2)

Model DY3002A1011

Mounting socket

Surface of pipe, tank, etc.

Immersion well

(Model 112624AA-J)

Seal the screwed

joint (R1/2).

Capillary tube

Cover setscrew

Capillary tube

Unscrew the setscrew with a screw-

driver to remove the cover from the

case.

Install the main unit and the

temperature sensor considering

length of the capillary. No direction is

specified for installing the main unit.

Capillary tube is wound up in a coil.

Unwind the tube only for the

necessary length.

Place the coil near the main unit.

Caution for installing the temperature sensor

For an accurate temperature control, install the temperature

sensor correctly.

Install it in a place where the representative temperature of

the controlled substance can be measured.

Knockout hole for wiring

Before the installation, remove the knockout hole on the top or

bottom surface of the case, which will be used to lead in the wires.

The capillary tube can be taken out from the top of the main unit.

Mount the main unit using the screws and nuts through the 3

mounting holes on the rear side of the case.

(Screws and nuts are included in accessories.)

Heat insulator

For mounting on a surface which is excessively heated, insert

a heat insulator between the back surface of the case and the

mounting surface.

Temperature sensor

The installation varies depending on applications.

For liquid, the immersion well (Model 112624AA-J) or the

pressure fitting (Model 83165370-001) is used.

For air duct, the temperature sensor holder (Model

DY3002A1011) is used.

These parts are to be ordered separately. For installation,

refer to the following figures.

Capillary tube

Never bend sharply, twist, or cut the

capillary tube.

The unit will be inoperative.

Allow enough clearance for setup

and adjustment.

Temp.

setting knob

Cover

Wall Mounting

Immersion well installation* Duct installation

Temperature sensor

Fix the capillary tube

with the spring clip

included in the

immersion well.

If the temperature sensor moves due to the

controlled substance orbends due to its own

weight, hold it straight.

Insertion length needs to be as short as possible

to avoid damage to thecapillary tube.

Seal the screwed

joint.

Tighten with

a wrench.

Place the washers to fit

the projection of a

washer and the groove

of another washer.

Temperature sensor of Model

TY6800Z, TTY6800Z

(Insert until it reaches the

bottom of the immersion well.)

Loading...

Loading...