HOW TO WIRE

THE PC100

The rear panel of the PC100 controller contains 36 screw

terminals for connecting #28 to #18 gauge insulated wire

(#18 gauge stranded twisted pair shielded cable is recom-

mended.)

A wire stripper and a small screwdriver are the only tools

required. Detailed diagrams in this section illustrate the

proper wiring procedures for all standard and optional

functions.

At installation, be sure to comply with the following

requirements:

• Disconnect power to the unit before attempting any

connection or service to the unit

• Avoid using machine power service for AC power. When

possible, a dedicated or lighting circuit is recommended

• Do not bundle or route signal lines with power lines

• Keep all lines as short as possible

• Use twisted pair shielded wire for all input wiring

• Observe all applicable local electrical codes

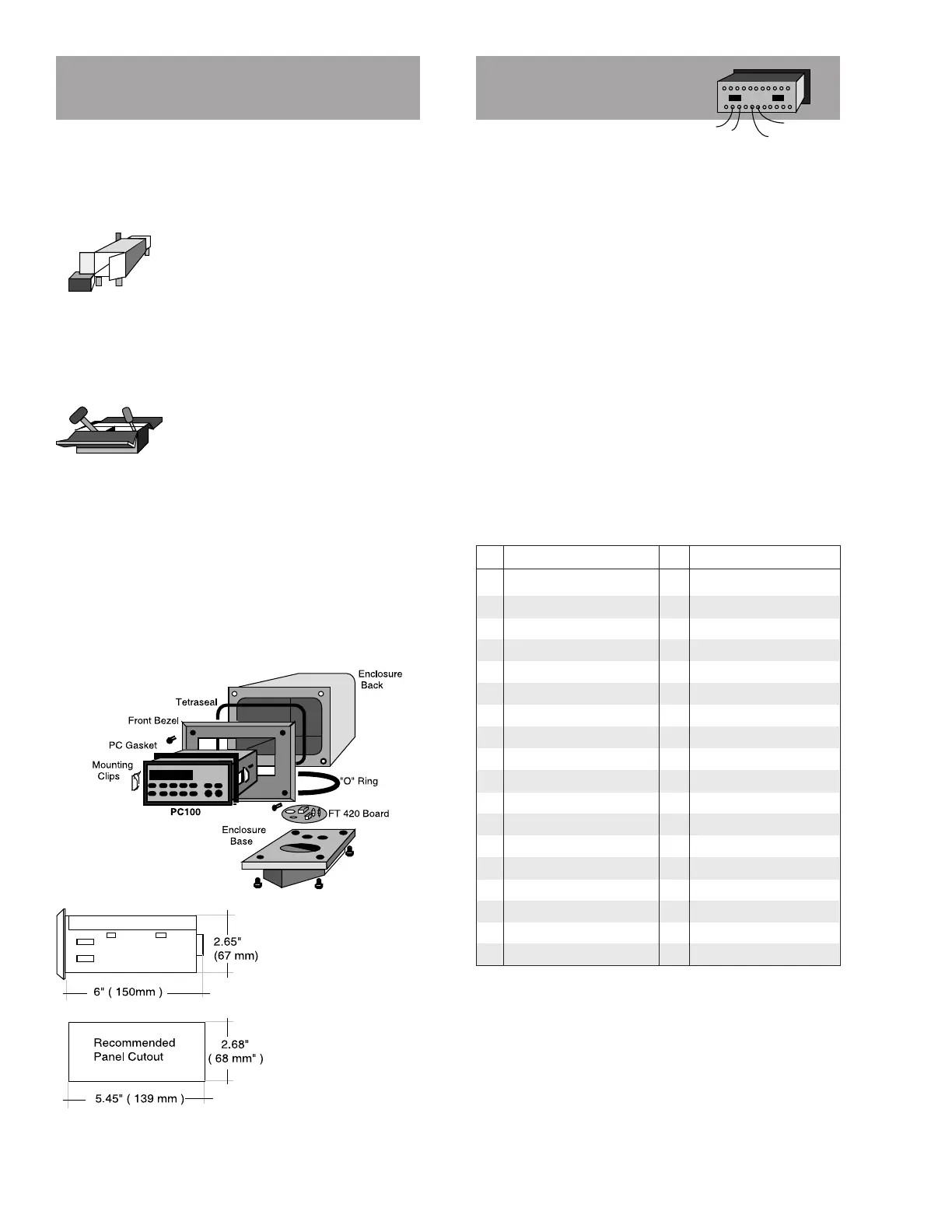

Terminal Identification List

No Function No Function

1 Reset Cycle Counter 19 DC Power Input

2 Resume Remote Input 20 15 VDC Power Output

3 Stop Remote Input 21 DC Common

4 Reset Totalizer 22 Relay K1 Contact NC

5 Transistor Output 1 23 Relay K1 Contact C

6 Transistor Output 2 24 Relay K1 Contact NO

7 Transistor Output 3 25 AC Power Input

8 Transistor Output 1A 26 AC Power Input

9 Transistor Output 2A 27 AC Power Input

10 Transmitter Input 2 28 AC Power Input

11 Low Frequency 2 29 Relay K2 Contact NC

12 DC Common 30 Relay K2 Contact C

13 Low Frequency 1 31 Relay K2 Contact NO

14 Transmitter Input 1 32 Chassis Ground

15 Function Inhibit 33 Serial Data Input (-)

16 Print Command 34 Serial Data Input (+)

17 Start Command 35 Serial Data Output (+)

18 Pulse Input Doubler 36 Serial Data Output(-)

CAUTION: To prevent accidents, power connection should

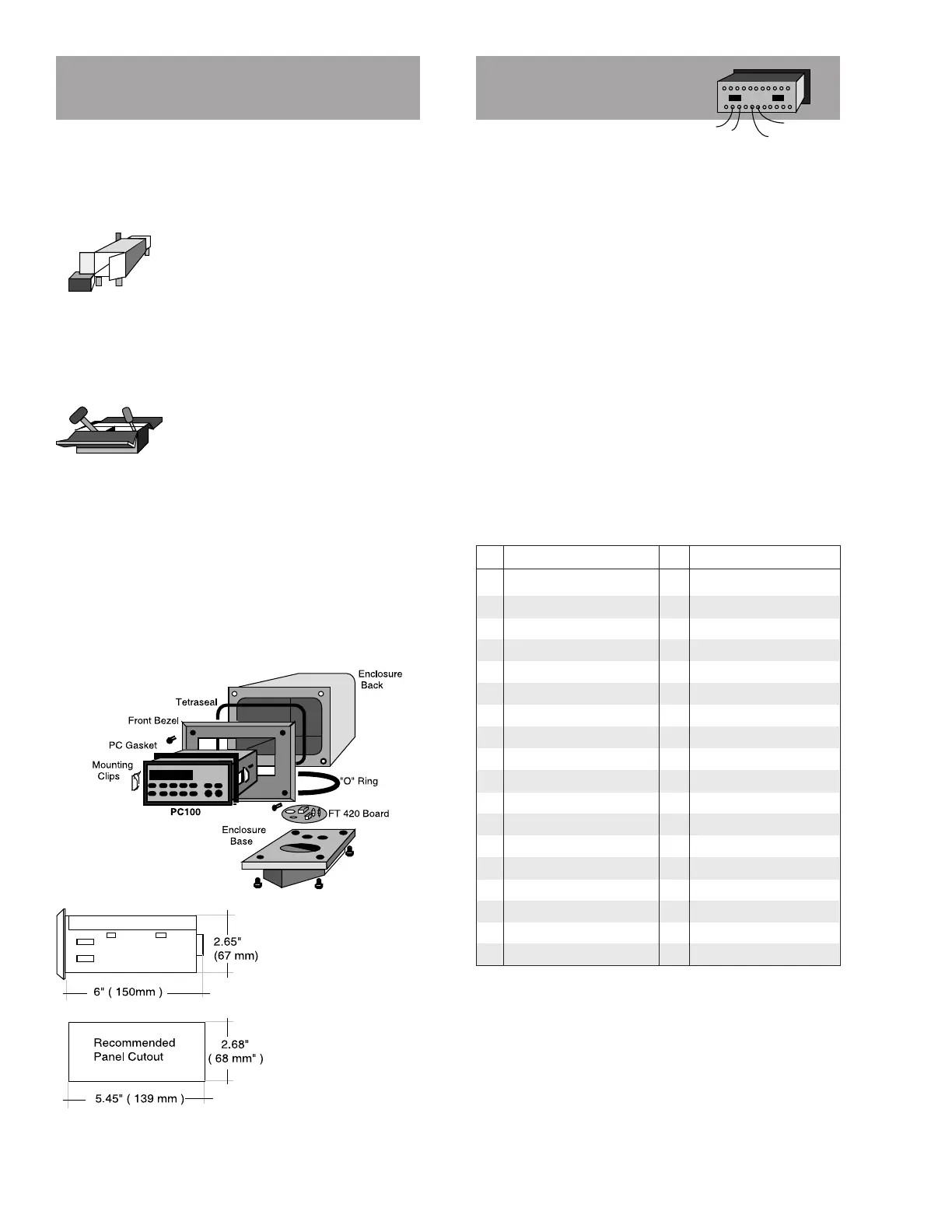

HOW TO UNPACK, ASSEMBLE

AND INSTALL THE PC100

4

Note: K1 relay coil jumper is factory wired to terminal 8.

K2 relay coil jumper is factory wired to terminal 9. At the

end of the batch, transistor outputs 2 and 2A (terminals 6

and 9) are energized. At prewarn, terminal outputs 1 and 1A

(terminals 5 and 8) are energized.

Note: If damage to the shipping container is obvious,

request that the carrier be present when the product is

unpacked. All claims for equipment damage during transit

are the sole responsibility of the recepient.

UNPACKING

After carefully unpacking the unit, check

for any visible sign of damage. If found,

notify the carrier for insurance purposes

and call the factory for possible replacement. Keep all

packing material in the event that the unit must be return

to the factory.

ASSEMBLY

The PC100 can be installed on the flow-

meter, on a wall or shelf, or in an instru-

mentation panel. The picture below shows

the exploded view of a meter or wall

mounted unit. In this configuration, the

PC100 is shipped separately and must be installed as shown.

(See wiring diagrams for proper transmitter signal connec-

tions.)

The basic unit is equipped for panel mount. To install:

1- Measure and cut mounting hole to the dimensions shown.

2- Install gasket around the mounting bezel.

3- Pass the unit through the front panel cutout.

4- Secure the unit to the panel with the mounting clips.

5- Complete wiring and reassemble unit.

Note: Operating tempera-

ture is 32° F to 130° F (0°

to 55° C) with a maximum

humidity of 85% non-con-

densing.

Always select a mount-

ing location with proper

ventilation and environ-

ment protection.

Loading...

Loading...