www.balluff.com 2english

BTL BNC_ 00- _ _ _ _ -C12NL_ _0-000S04 / BTL ZNC_ 00- _ _ _ _ -C12NL_ _0-000S04

Magnetostrictive Linear Position Sensor – Rod Style

953559_AA ∙ EN ∙ E22; subject to modification.

Installation

For examples and further information on

installation, see the user’s guide.

Suitable nuts for the mounting thread are

available as accessories.

We recommend using non-magnetizable material to mount

the BTL and magnet.

If using magnetizable material, the BTL must be protected

against magnetic interference through suitable measures

(e.g. spacer ring made of non-magnetizable material, a

suitable distance from strong external magnetic fields).

If installed in a hydraulic cylinder, the magnet should not

make contact with the rod. Minimum bore diameter in the

support piston:

Rod diameter Bore diameter D2

10.2mm At least 13mm

NOTICE

Interference in function

Improper installation can compromise the function of the

BTL and result in increased wear.

► Ensure that the contact surface of the BTL is in full

contact with the mounting surface.

► Seal the hole perfectly (O-ring/flat seal).

Mounting in a hole with internal thread (mounting

hole)

Depending on the version, the BTL comes with an

M18×1.5 thread (according to ISO) or a 3/4“-16UNF

thread (according to SAE) to secure it.

1. Make a mounting hole with thread (possibly with

countersink for the O-ring).

2. Screw the BTL with mounting thread into the mounting

hole (max. torque75Nm).

Mounting in a through-hole

1. Guide the BTL through the hole.

2. Screw the mounting nut (max. torque75Nm) onto the

mounting thread on the rod side.

Further steps

► Install the magnet (accessory).

► From measuring length of 500mm: Support the rod

and if necessary screw on at the end.

Cable routing

Defined ground!

The BTL and the control cabinet must be at the

same ground potential.

Magnetic fields

The position measuring system is a magnetostrictive

system. Ensure that there is sufficient distance between

the BTL and the transducer/holding cylinder and strong,

external magnetic fields.

Cable routing

All cables between BTL, control and power supply must

be routed tension-free. In order to avoid electromagnetic

interference, ensure sufficient distance to cables carrying a

heavy current and cables with high-frequency voltage

signals (e.g. of frequency converters).

Cable length

For IO-Link operation, the maximum cable length is 20m.

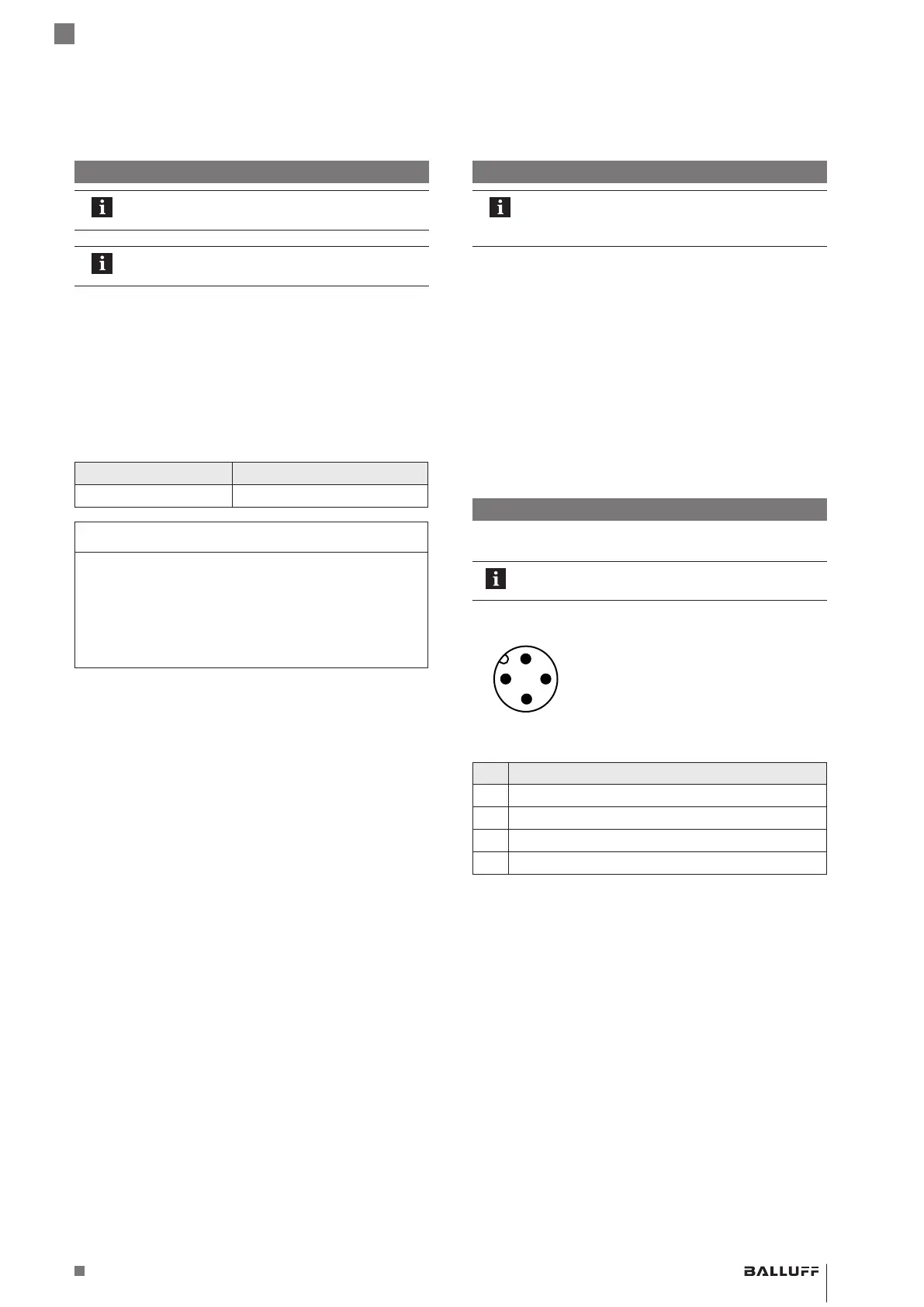

Electrical Connection

The electrical connection is made using a connector.

See the information about cable routing.

4

3

1

2

Pin assignment ofS04 (view from

above on BTL)

Pin Signal

1 L+ (18…30V)

2 Not assigned

1)

3 L− (GND)

4 C/Q (IO-Link communication)

1)

Non-assigned wires can be connected to GND on the control side.

Loading...

Loading...