www.balluff.com 3english

BTL PF _ 400- _ _ _ _ -C15A _ _ _ _ -000S35

Magnetostrictive Linear Position Sensor – Profile Style

955203_AA ∙ EN ∙ E22; subject to modification.

Shielding and cable routing

Defined ground!

The BTL and the control cabinet must be at the

same ground potential.

Shielding

Observe the following instructions to ensure

electromagnetic compatibility (EMC):

– Connect BTL and controller using a shielded cable.

Shielding: Braided copper shield with minimum 85%

coverage.

– Shield is internally connected to connector housing.

Magnetic fields

The position measuring system is a magnetostrictive

system. Ensure that there is sufficient distance between

the BTL and the transducer/holding cylinder and strong,

external magnetic fields.

Cable routing

All cables between BTL, control and power supply must

be routed tension-free. In order to avoid electromagnetic

interference, ensure sufficient distance to cables carrying a

heavy current and cables with high-frequency voltage

signals (e.g. of frequency converters).

Cable length

BTL …-C15AA/A1… Max. 30 m

1)

BTL …-C15AE/A5/AC/A3… Max. 100 m

1)

1)

Prerequisite: Construction, shielding and routing preclude the effect of

any external noise fields.

Display elements

Signal Meaning

Green Normal function

Yellow flashing,

3Hz

Warning

Magnet is outside the measuring

range.

Red flashing, 1Hz Measurement error

No magnet

Red flashing, 3Hz Output error

1)

Short-circuit at voltage output or

interruption on current output.

1)

Is only displayed for versions with 2 current outputs if the error is

present at the same time at both outputs.

With 1magnet and 2 outputs the priority of the LED

display is as follows (highest to lowest priority):

Output error, measurement error, Warning, ormal function

For FMM (Flexible Magnet Mode) with 1magnet the LED

display relates to output 1 (output 2 issues the error value

continuously).

For FMM (Flexible Magnet Mode) with 2magnets the LED

display shows the status with the highest priority of both

outputs.

More than 2 magnets are ignored.

Installation (continued)

The magnetostrictive linear position sensor is electrically

isolated from the machine with the supplied insulating

bushes.

1. Guide the BTL into the mounting clamps.

2. Attach the BTL to the base using mounting screws

(tighten screws in the clamps with max.2Nm).

3. Install the magnet (accessory).

The magnetostrictive linear position sensor in

profile housing is suitable both for floating, i.e.

non-contacting magnets and for captive

magnets (see images).

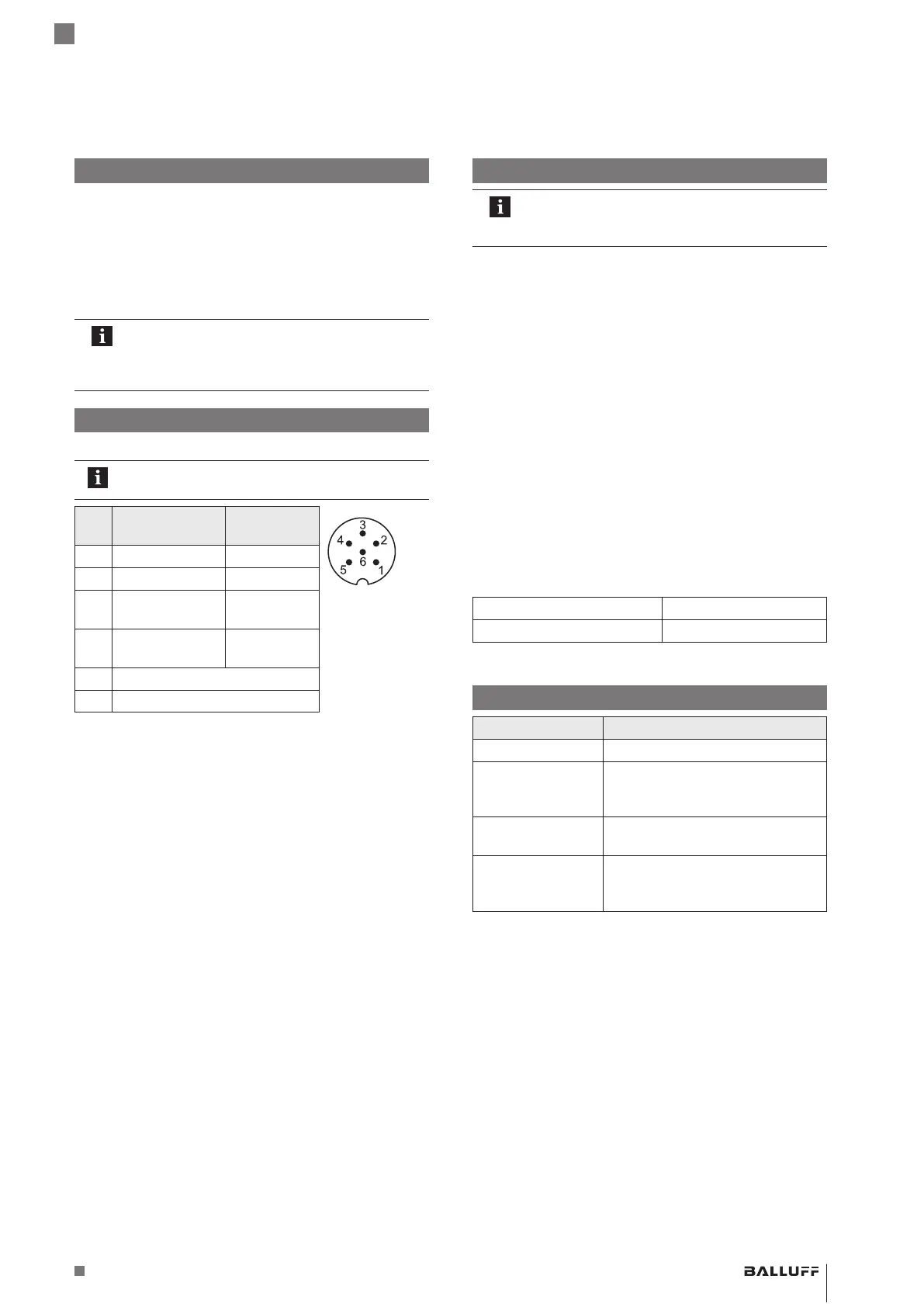

Electrical connection

The electrical connection is made using a connector.

Note the information on shielding and cable

routing.

Pin C15AA/A1… C15AE/A5/

AC5…

Pin assignment

ofS35 (view

from above on

BTL)

1 Output1 Output1

2 0V (output1) 0V

3 Output2 Not

assigned

1)

4 0V (output2) Not

assigned

1)

5 10…30V

6 GND

2)

1)

Unassigned leads that are not used can be connected to the GND on

the controller side but not to the shield.

2)

Reference potential for supply voltage and EMC-GND.

Loading...

Loading...