*

*

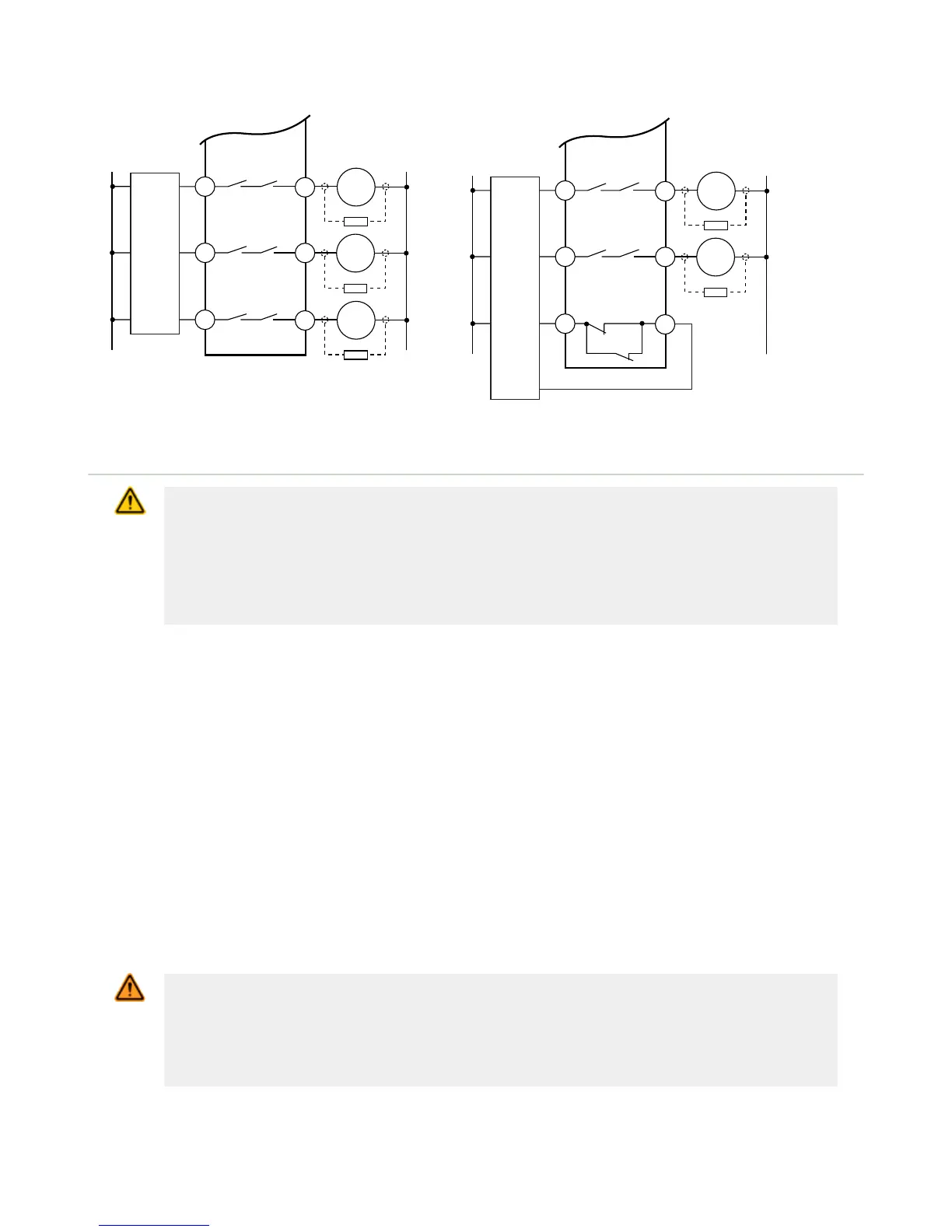

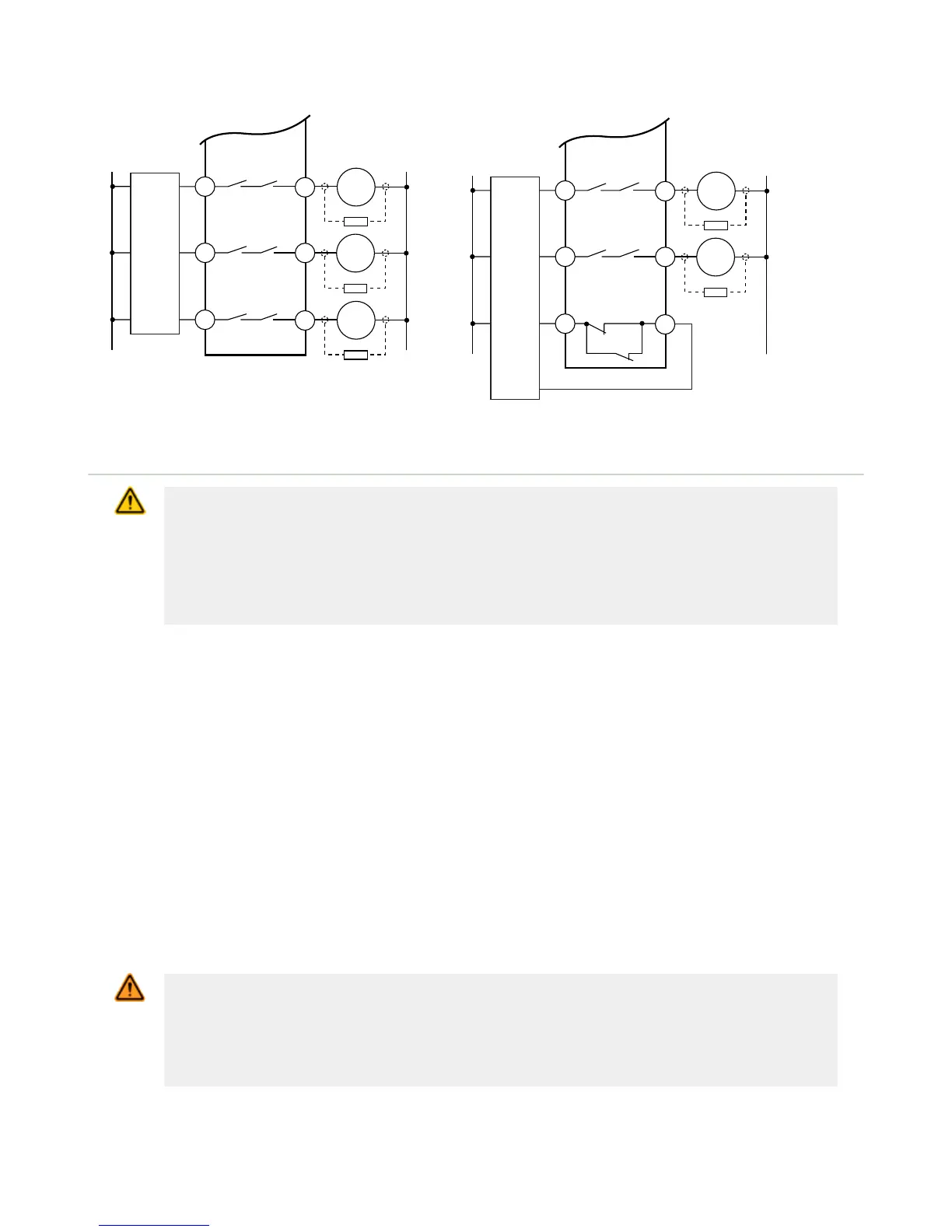

L2

MSC1

MSC2

Machine

Master Stop

Control Elements

*Arc suppressors

(see WARNING)

K1

A

6A max.

6A max.

6A max.

K2

A

K1

B

K2

B

K1

C

K2

C

*

MSC3

13

14

23

24

33 34

L1

Machine

Control

Circuits

ES-FA-9AA

*

*

L2

MSC1

MSC2

Machine

Master Stop

Control Elements

*Arc suppressors

(see WARNING)

K1

A

7A max.

7A max.

7A max.

K2

A

K1

B

K2

B

K1

C

K2

C

13 14

23 24

31 32

L1

Machine

Control

Circuits

ES-FA-11AA

Feedback

(optional)

Figure 6. Machine Control Circuit Connections

Initial Checkout Procedures

CAUTION: Disconnect Power Prior to Checkout

Before performing the initial checkout procedure, make certain all power is disconnected

from the machine to be controlled.

Dangerous voltages may be present along the Safety Module wiring barriers whenever power to the

machine control elements is On. Exercise extreme caution whenever machine control power is

or may be present. Always disconnect power to the machine control elements before opening

the enclosure housing of the Safety Module.

1. Remove power from the machine control elements.

2. Ensure the safety device is in a STOP or "open-contact" state (e.g., actuate the E-stop switch to open its contacts).

3. Apply power to the Safety Module at terminals A1 and A2 (see wiring diagrams). Verify that only the Input Power

indicator (see Figure 1 on page 2) is ON. If either input channel 1 (K1) or input channel 2 (K2) indicators are ON at this

point, disconnect the input power and check all wiring. Return to step 2 after the cause of the problem has been

corrected.

4. Reset or otherwise cause the safety device to reach an ON or "closed-contact" state (e.g., arm the E-stop switch to

close its contacts).

Automatic reset: Ch1 (K1) and Ch2 (K2) indicators should come ON, and the safety output contacts should close.

Manual reset: From an open condition, close the reset switch for approximately ¼ second, and then re-open. The Ch1

(K1) and Ch2 (K2) indicators should both come ON steady at this time. If either indicator comes ON before the reset

switch is opened, disconnect the input power and check all wiring. Return to step 2 after correcting the problem.

5. Cause the safety device to generate a STOP or "open-contact" state (e.g., actuate the E-stop switch to open its

contacts). The Ch1 (K1) and Ch2 (K2) indicators should turn OFF simultaneously. If either indicator remains ON,

disconnect the input power and check all wiring. Return to step 2 after the cause of the problem has been corrected.

6. If more than one safety device is series-connected to the Safety Module, run the above checkout procedure individually

for EACH device.

7. Close and secure the enclosure in which the Safety Module is mounted. Apply power to the machine control elements

and perform the Periodic Checkout Procedure.

WARNING: Multiple Safety Devices

When two or more safety devices are used, each device must be individually actuated,

causing a Stop or open-contact condition, then reset/rearmed and the Safety Module reset (if

using manual reset mode). This allows the monitoring circuits to check each device and its wiring to

detect faults. Failure to test each device individually in this manner may result in undetected

faults and create an unsafe condition which may result in serious injury or death.

ES-FA-9AA and ES-FA-11AA E-Stop Safety Module

P/N 60606 Rev. G www.bannerengineering.com - Tel: +1-763-544-3164 9

Loading...

Loading...