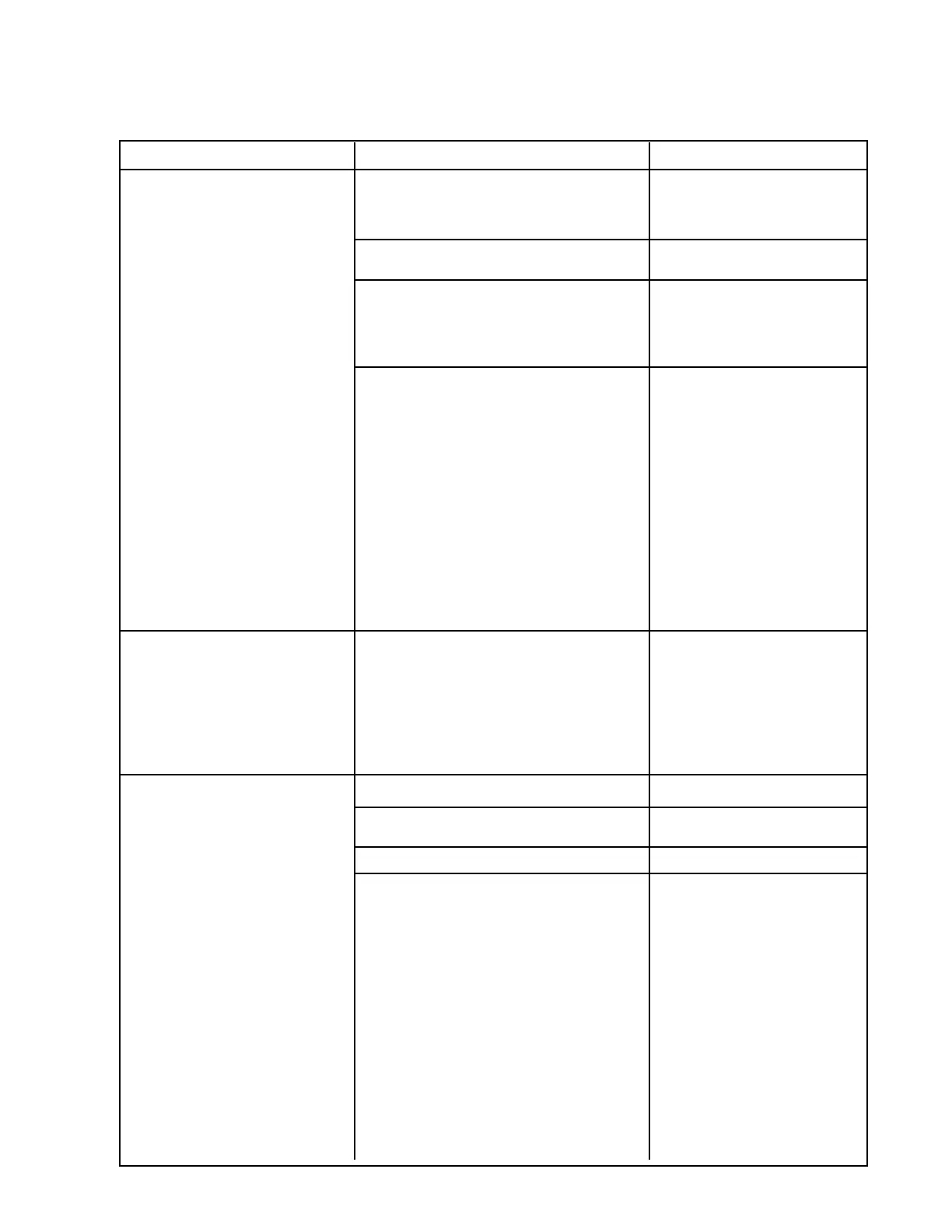

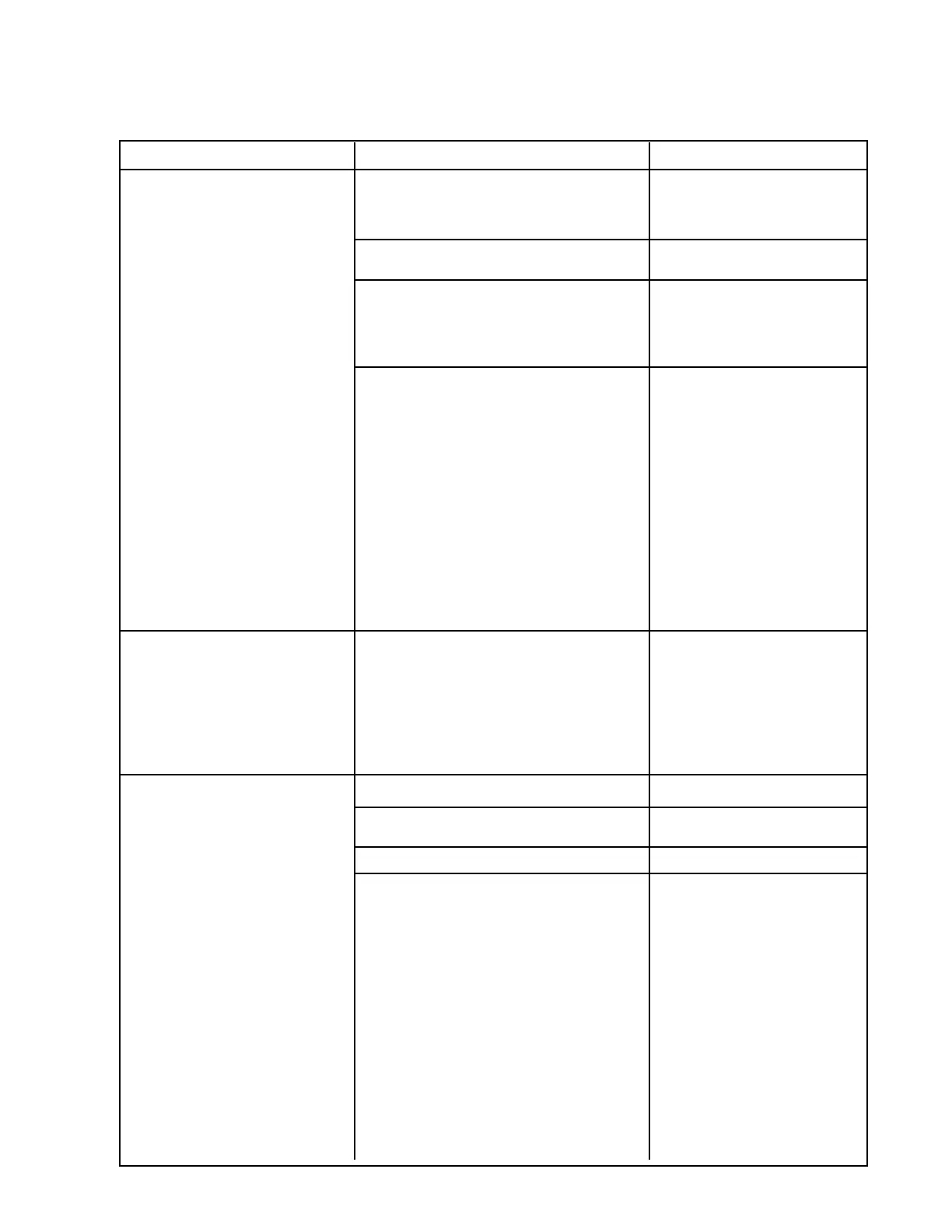

I. System appears dead. (Actuator fails to

move to full fuel)

Check connections to battery.

Note: Turn off power and reconnect Purple lead.

III. Actuator hunts during operation.

Note: Reconnect actuator leads properly after

completing this test.

II. Actuator lever goes to full fuel whenever

the power is turned "ON" and engine is

not running.

1. CHECK CONTROLLER by removing actuator lead to

Purple lead and turning power “ON” to controller.

a. Actuator goes to full fuel.

b. Actuator does not go to full fuel.

1.

CHECK BATTERY VOLTAGE AT CONTROLLER

with power switch “ON”. Measure DC battery voltage

between the Red (+) and Black (-) leads. Battery

voltage should be present.

2.

CHECK LINKAGE. Manually operate linkage to see

that it is not sticking or binding.

3.

NO SIGNAL OR WEAK SIGNAL FROM MAGNETIC

PICKUP. Measure AC voltage between the White and

Black/White leads on controller while cranking engine.

Voltage should be 2.5 volts RMS or greater. (AC input

impedance of meter must be 5000 ohms/volt or greater.)

4.

CHECK ACTUATOR with power “ON” to controller.

Measure following terminals on control box with respect

to the Black lead. All points should read BATTERY

VOLTAGE. (+0.00/-0.75 VDC)

a. Purple lead to Black lead on controller.

b. Second Purple lead to Black lead on controller.

(Continue this test only if battery voltage is not

present.)

c. Following checks are terminals on the actuator

and the Black lead on controller.

1) Low voltage (1.0-2.0 VDC) at either

actuator connector.

2) Battery voltage at both actuator connectors.

3) Battery voltage at one actuator lead but not

at the other.

Check for damage to or improper

adjustment of magnetic pickup.

Replace or re-adjust.

Free linkage.

Replace controller if battery voltage

is not present at both Purple leads.

Broken actuator lead.

Replace actuator.

Broken actuator lead.

1.

Linkage or rod end bearings sticking or binding.

2.

Improper linkage arrangement.

(Stroke too short or improper non-linear linkage used)

3. Improper governor adjustment.

4. Inadequate power supply voltage.

a. Turn power switch "OFF".

b. Connect a DC voltmeter to Red and Black leads

at control box.

c. Disconnect both leads to actuator at Purple

leads of control box.

d. Connect one actuator lead to the Red lead and

one actuator lead to the Black lead of the

control box.

e. Momentarily turn "ON" the DC power. The

actuator should go to full fuel and the DC

voltage must be greater than 80% of supply.

24 VDC @ 80% = 19.2 VDC

12 VDC @ 80% = 9.6 VDC

Check for shorted actuator lead.

Replace Controller because it should not

cause actuator lever to go to full fuel with

engine not running.

Lubricate or replace.

Readjust calibration.

If actuator doesn’t get to full fuel, then

check actuator leads. If voltage is less

than specified, check for loose or poor

connections to battery, or get larger supply

leads or larger power supply.

See installation information.

LINEAR TROUBLESHOOTING CHART

Corrective ActionProblem Detection

3

Loading...

Loading...