9

3-6. Complete Calibration (Cont.) (DP=Differential Pressure)

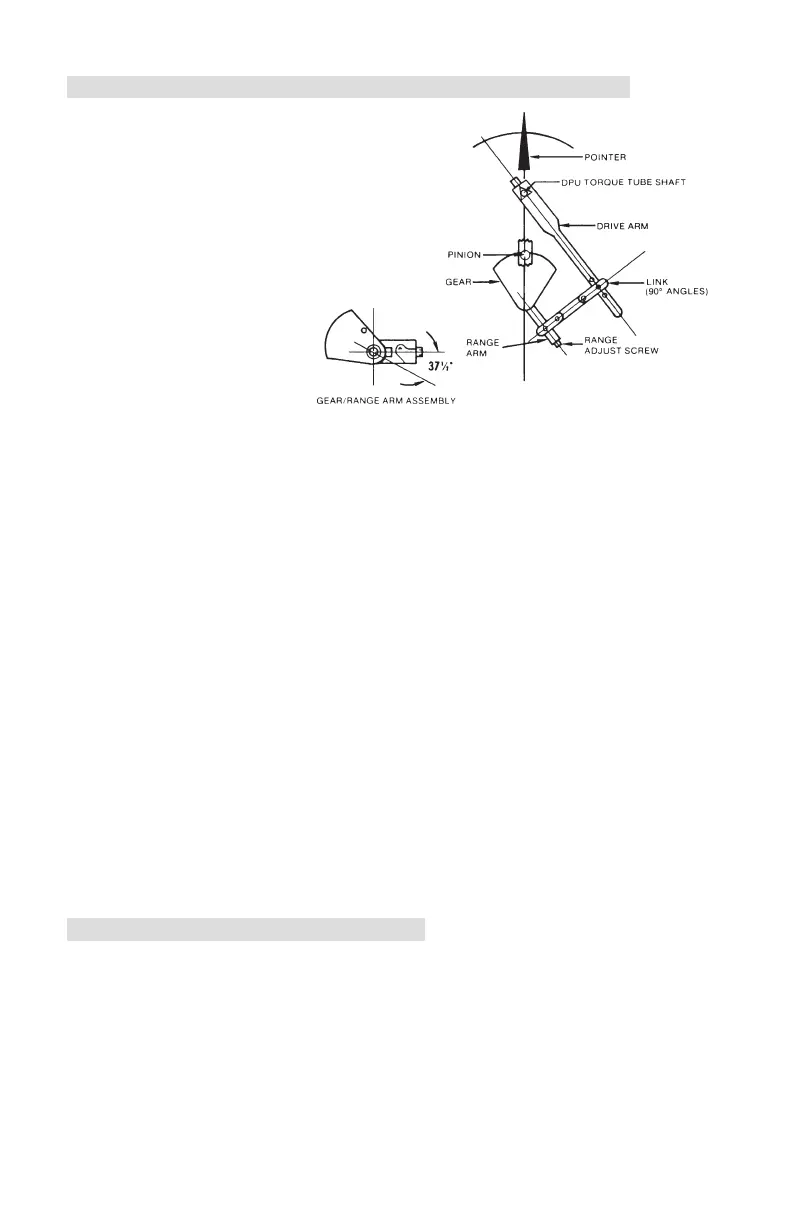

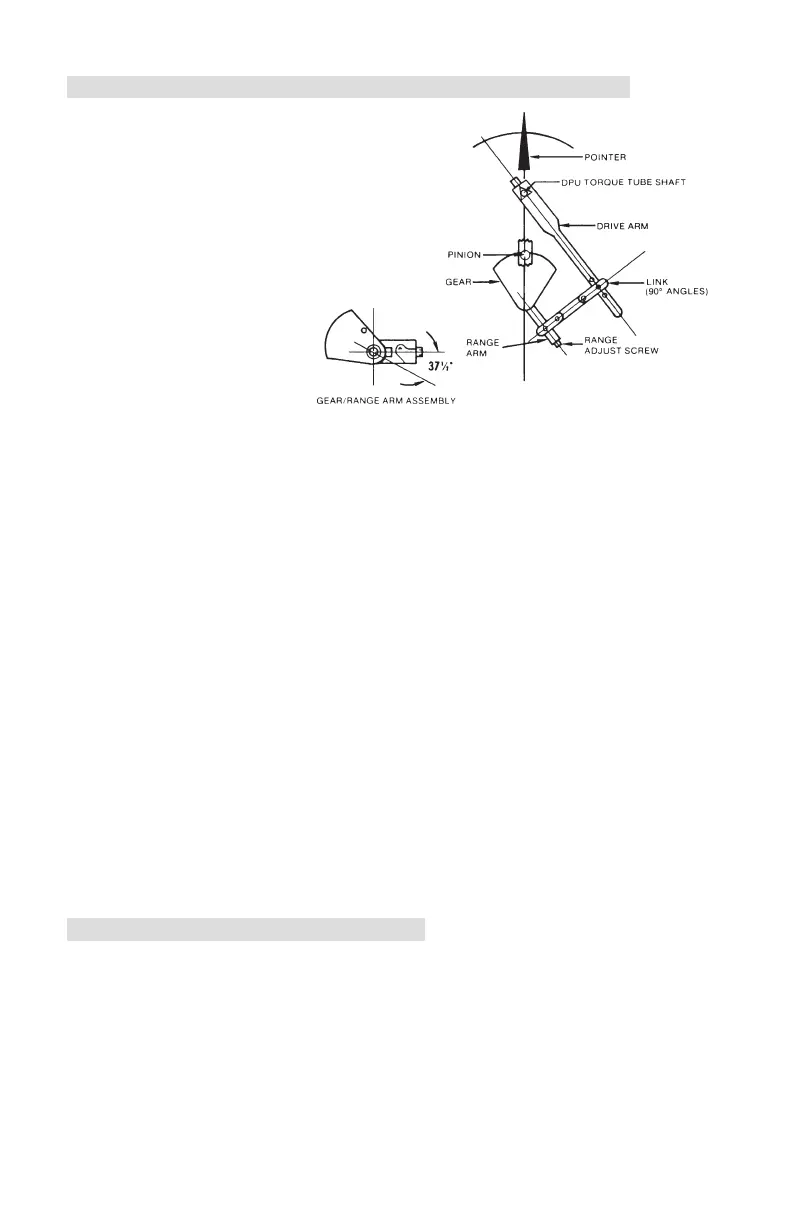

2. Attach linkage between drive arm and

movement. Fig. 3-3 shows alignment

at 50% DP. Inspect parts for straight-

ness and pivot-t without binding.

3. Set pointer at zero on scale by slip-

ping pointer on hub. Hold tip of

pointer and turn hub with wrench.

4. Apply 100% DP. If pointer exceeds

100% on scale,

lengthen range arm.

Remove pressure.

5. Set zero and span,

using hub for zero

adjustment and

range adjust screw

on the movement for span adjustments.

6. Apply 50% DP. If pointer does not indicate 50% scale, a linearity adjust-

ment is necessary. Loosen drive arm screw and move arm to shift pointer

in direction of error (approx. 10:1). Tighten drive arm screw.

7. Release pressure and reset pointer at zero. Check the span. If gear in move-

ment reaches limit of travel as a result of linearity adjustment (step 6), slip

range arm along gear approximately 5 degrees from normal 37.5 degree

angle to approximately 43 degrees. Range arm is slipped by applying pres-

sure to range arm with thumb, while holding gear rmly in place. Retest

pointer response at 50% and 100% DP, and adjust linkage until readings

are acceptable.

8. Apply 0%, 25%, 50%, 75%, 100%, 75%, 50%, 25%, and 0% of DP

consecutively to instrument without overshoot. Lightly tap indicator to over-

come friction. Pointer should accurately indicate each applied pressure.

10. Test instrument repeatability by applying 0%, 50%, 0%, 50% DP. Indicator

should accurately indicate each applied pressure.

11. Set overrange stops to prevent pointer from striking snubbers on scale. See

para. 3-7 (Overrange Stop Adjustment). Tighten all screws. Test setting by

manually moving pointer from zero position to 50%, then let the pointer

return freely. An off-set in zero reading indicates pointer slippage. If neces-

sary, tap pointer hub to tighten it to shaft.

3-7. Overrange Stop Adjustment

1. Apply sufcient pressure to the high pressure housing to deect the pointer

against the snubber on the scale plate. Slide the upper overrange stop

against the drive arm and tighten the overrange stop screw.

2. Apply sufcient pressure to the low pressure housing to deect the pointer

against the zero stop snubber on the scale plate. Slide the zero-stop against

the drive arm and tighten the zero-stop screw.

3. Remove the pointer and calibration scale. Replace the pointer at zero

(adjust zero as necessary). Replace the lens and bezel assembly.

Figure 3-3. Linkage at 50% DP

Loading...

Loading...