-

A periodic inspection should be made of the unit to insure it is clean and free from accumulations of

dust and moisture. Verify that all terminal connections of the MVC-300 and the voltage regulator are

tight.

In the event of failure/defective operation of the unit, Table 4-2 provides information to determine the

probable cause of the malfunction and the solution. Refer to Paragraph 3-3 and to Figure 3-4 for the

bench test procedure.

Due to a protective coating, repair/replacement of individual components on the printed circuit board

assembly should not be attempted and the complete replacement of the board is recommended.

When ordering replacement parts from Basler Electric always specify the part number, the quantity

and the description of the item.

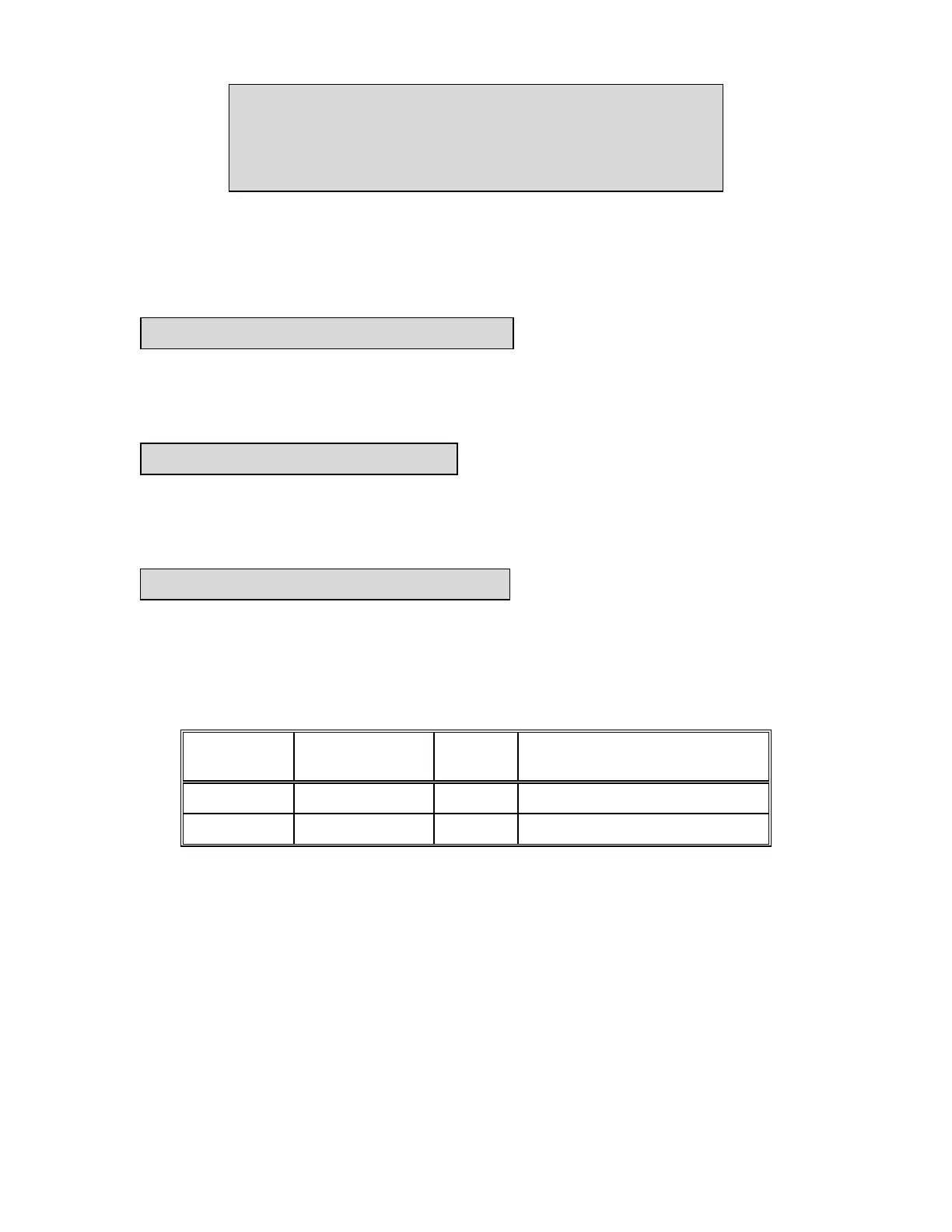

Table 4-1. Replacement Parts List.

Reference

Designator

Part

Number Quantity Description

---------------- 9 1210 01 103 1 Printed Circuit Board Assembly

F1,F2 04592 2 Fuse, 10 A, 250 V

SECTION 4

MAINTENANCE AND TROUBLESHOOTING

4-1. PREVENTIVE MAINTENANCE

4-2. TROUBLESHOOTING

4-3. RECOMMENDED SPARE PARTS

Loading...

Loading...