Mounting and wiring

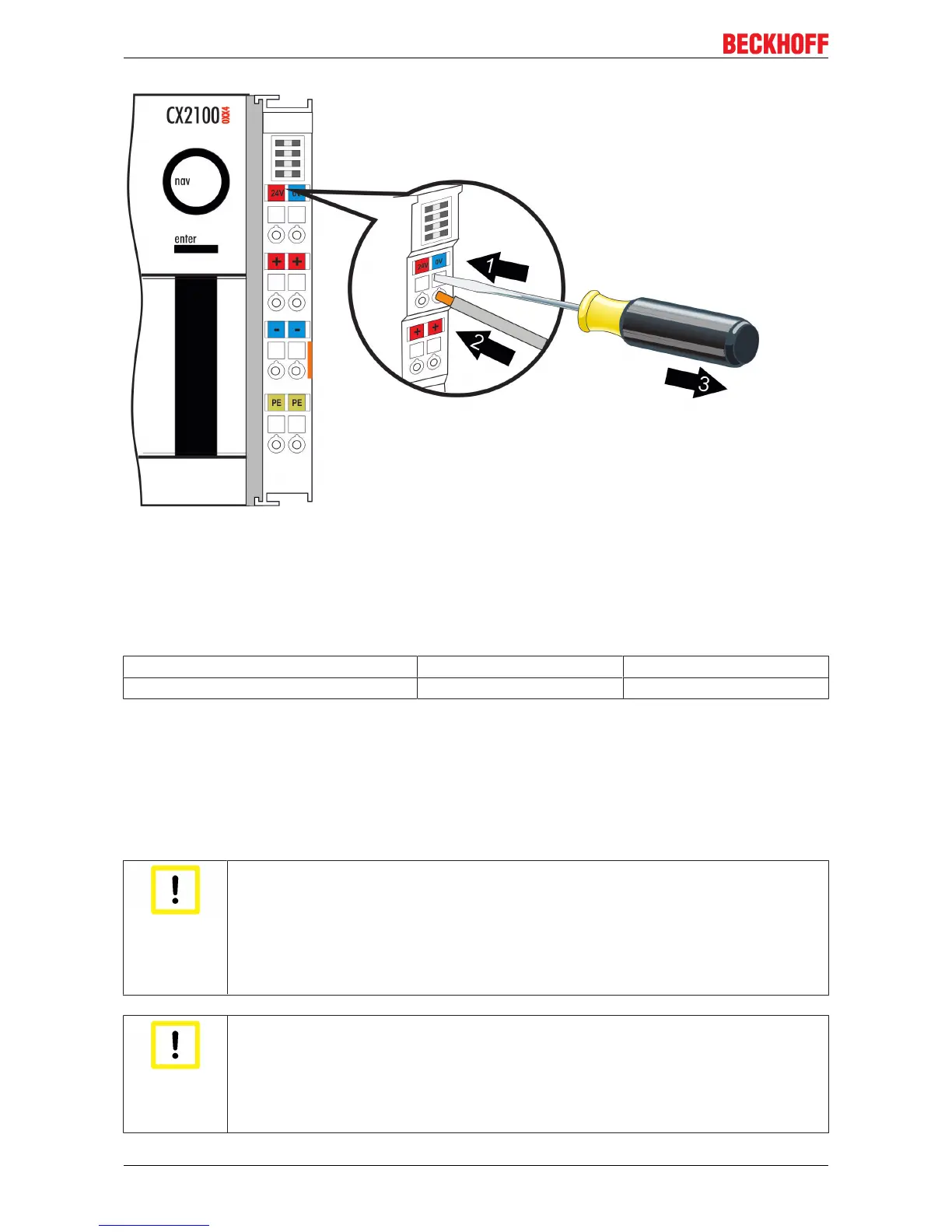

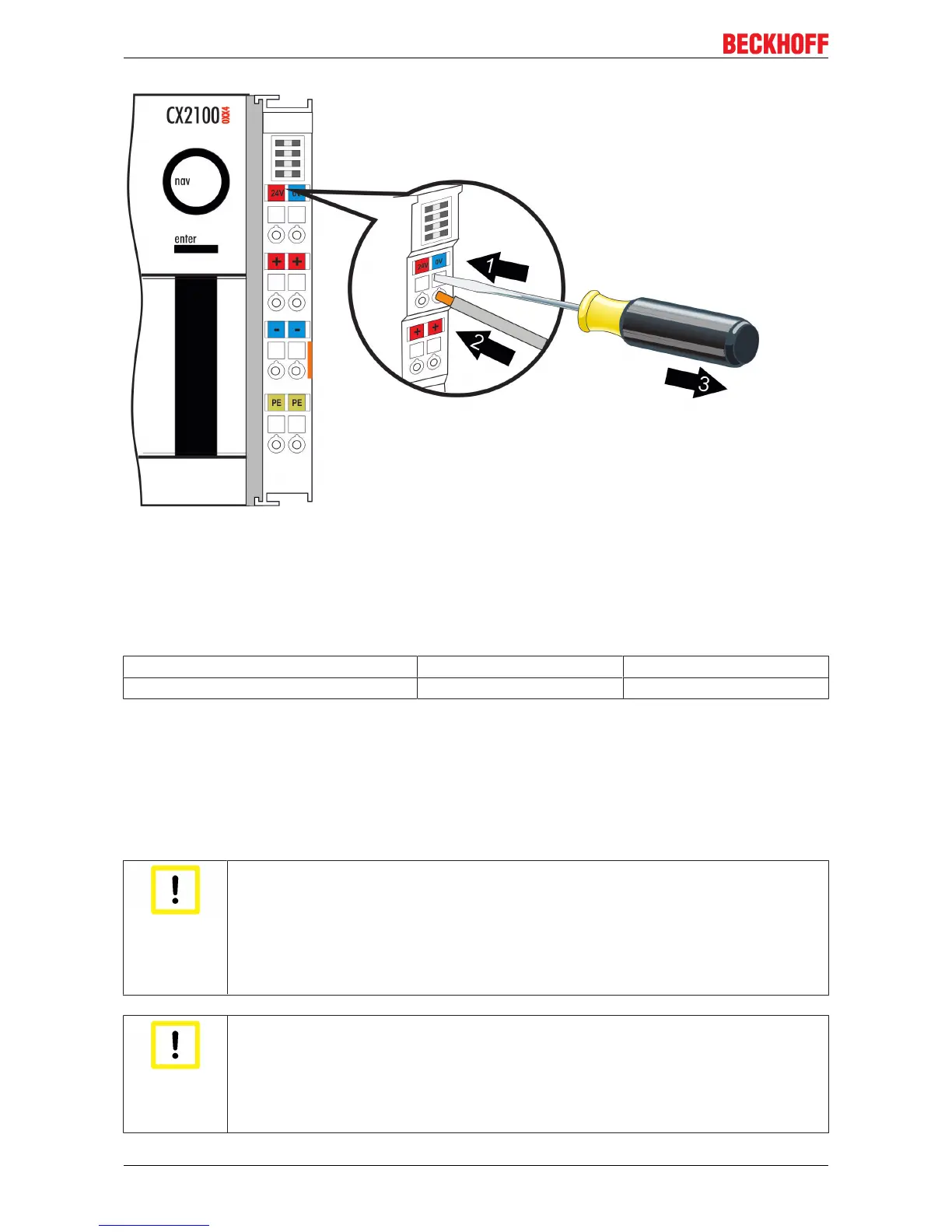

The terminals are implemented in spring force technology. Connect the cables as follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the square opening

above the terminal.

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire safely and

permanently.

Wire cross section 0,5 ... 2.5 mm

2

AWG 20 .. AWG 14

Strip length 8 ... 9 mm 0.33 inch

LED

If the power supply unit is connected correctly and the power supply is switched on, the two upper LEDs in

the terminal prism are green. The left LED (Us) indicates the CPU supply. The right LED (Up) indicates the

terminal supply. The other LEDs indicate the Terminal Bus status. A detailed description of the LEDs can be

found in section “LED troubleshooting”.

PE power contacts

Attention

Power contact “PE”

The “PE” power contact must not be used for other potentials. “PE” and “0V” (24 V system

supply) must be at the same potential (connected in the control cabinet). The cabling in the

control cabinet must be done in accordance with the standard EN 60204-1:2006 PELV =

Protective Extra Low Voltage. EN 60204-1:2006 section 6.4.1:b: one side of the circuit or

one point of the energy source of this circuit must be connected to the protective conductor

system.

Attention

Interruption of the power supply / switching off

The device may not be switched off by disconnecting the ground. The 24 V line must al-

ways be disconnected, as otherwise current may continue to flow via the screen depending

on the device. Any connected devices with their own power supply (e.g. a panel) must have

the same potential for “PE” and “GND” as the CX system (no potential difference). Other-

wise damage can occur both to the controller and to the periphery.

CX2100-09x434 Version: 1.3

Loading...

Loading...