Parameterization and commissioning

EL6731112 Version: 2.8

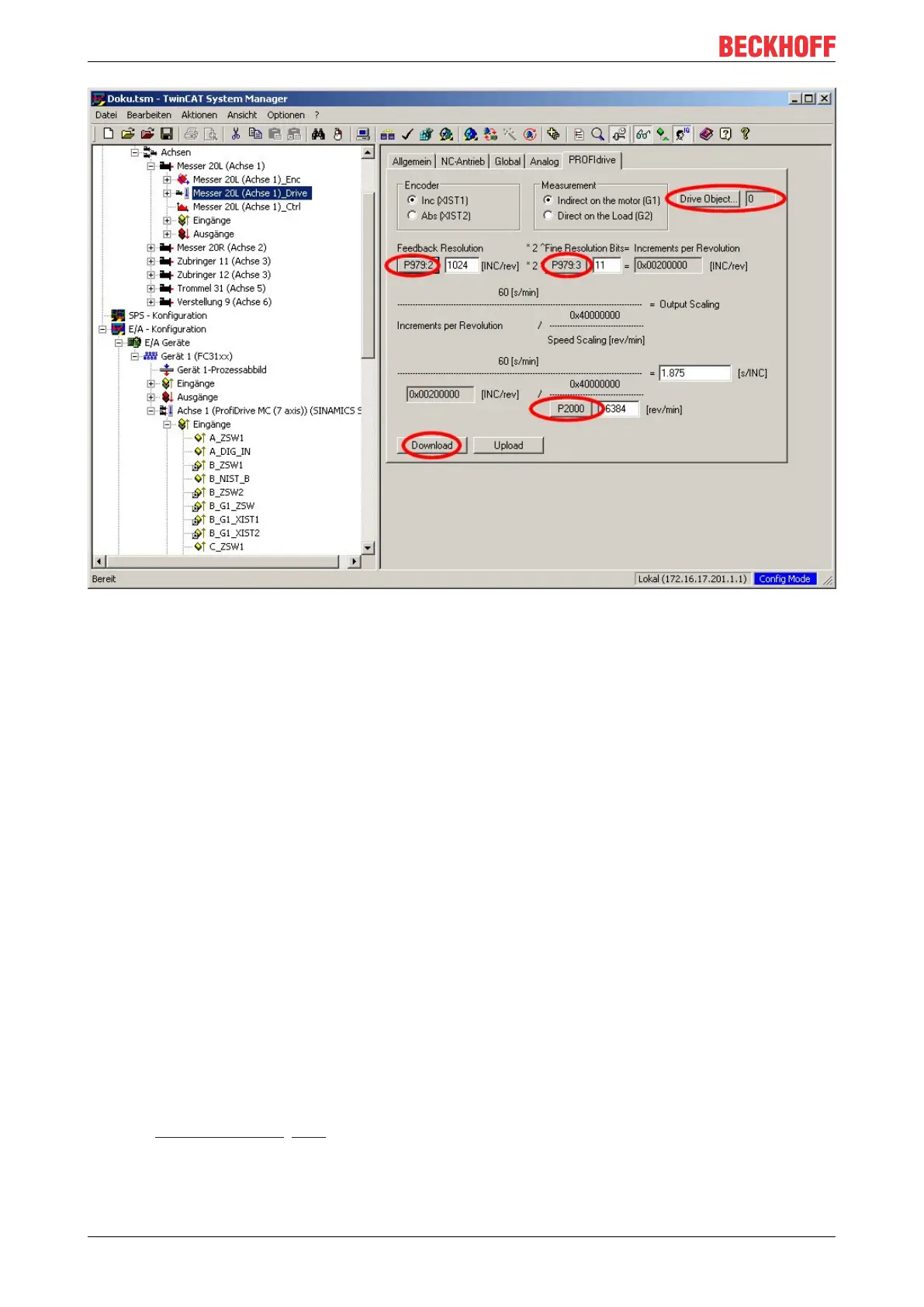

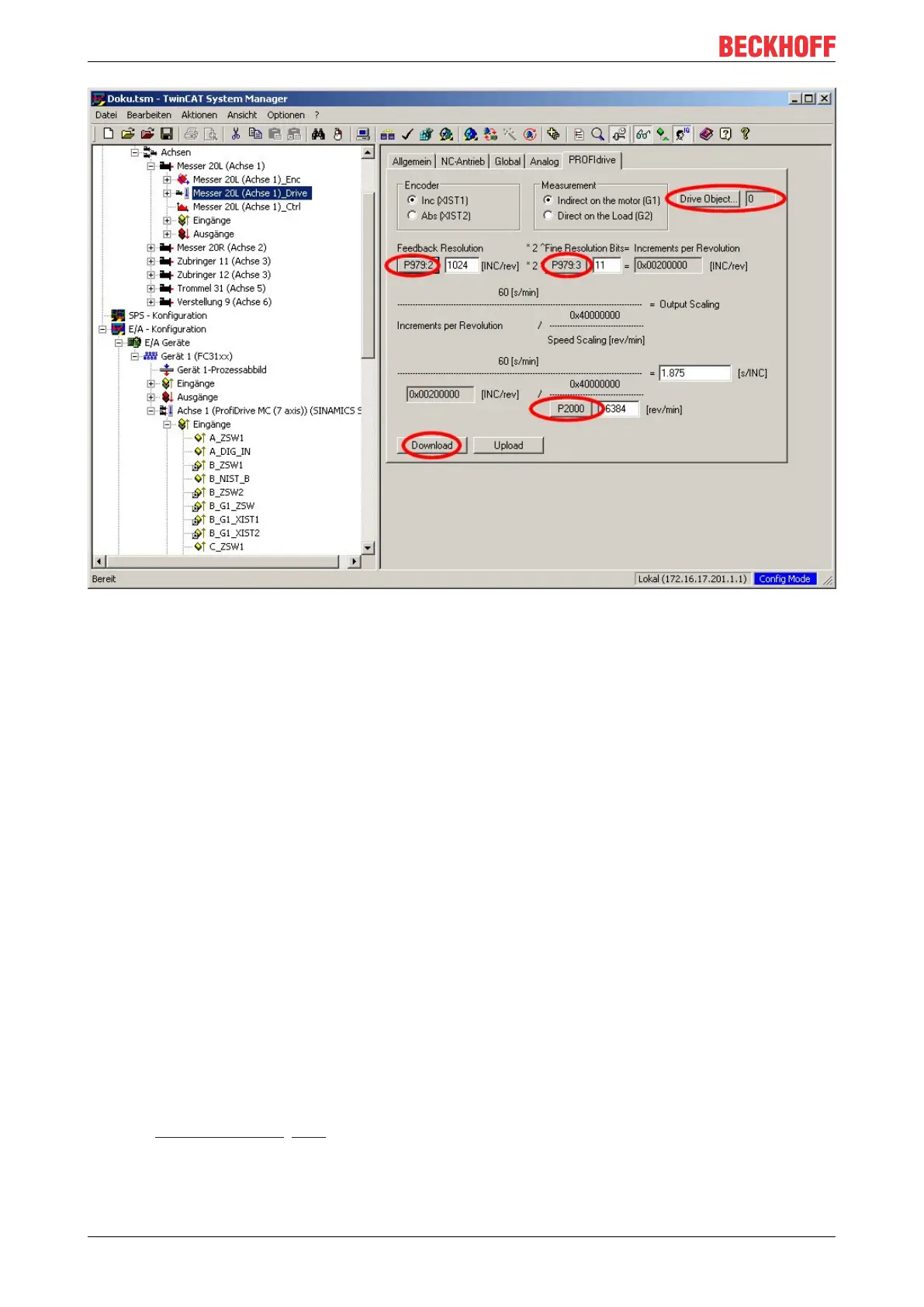

Fig.112: PROFIdrive tab, reading motor parameters

The "PROFIdrive" tab of the axis drive (in the current example Messer 20L(Axis 1)_Drive) features a dialog

for reading motor parameters from the drive. To this end the drive object number from the STARTER

software has to be specified. The respective buttons can then be used to read the encoder resolution via

parameters P979.2, P979.3 and P2000. Alternatively, these parameters can be read with the STARTER

software and manual written into the input fields. In both cases the values are transferred to TwinCAT via the

Download button.

Together with the mechanical data (e.g. transmission ratio) of the axis, the value INC/rev (increments per

revolution) can be used to calculate the scaling factor (in the linear axis example in mm/INC).

Formula

Scaling factor = path per revolution of the drive shaft / (gear ratio x increments per revolution) Gear ratio =

motor shaft revolutions / drive shaft revolutions

Example conveyor belt:

300mm feed per shaft revolution, gear ratio 10, encoder resolution 20000H = 2097152DEC INC/rev scaling

factor = 300mm/rev / (10 x 2097152 INC/rev ) = 0.000014305mm/INC

Example drum rotation:

Angle= 360° per shaft revolution, gear ratio 17.08, transmission via toothed belt 64/50, encoder resolution

20000H = 2097152DEC INC/rev scaling factor = 360°/rev / (17.08 x 64/50 x 2097152 INC/rev ) =

0.0000078519 mm/INC

Setting the encoder parameter scaling factor

Enter the determined value [}111] as the scaling factor for the encoder in the Global tab and accept the

values through Download

Loading...

Loading...