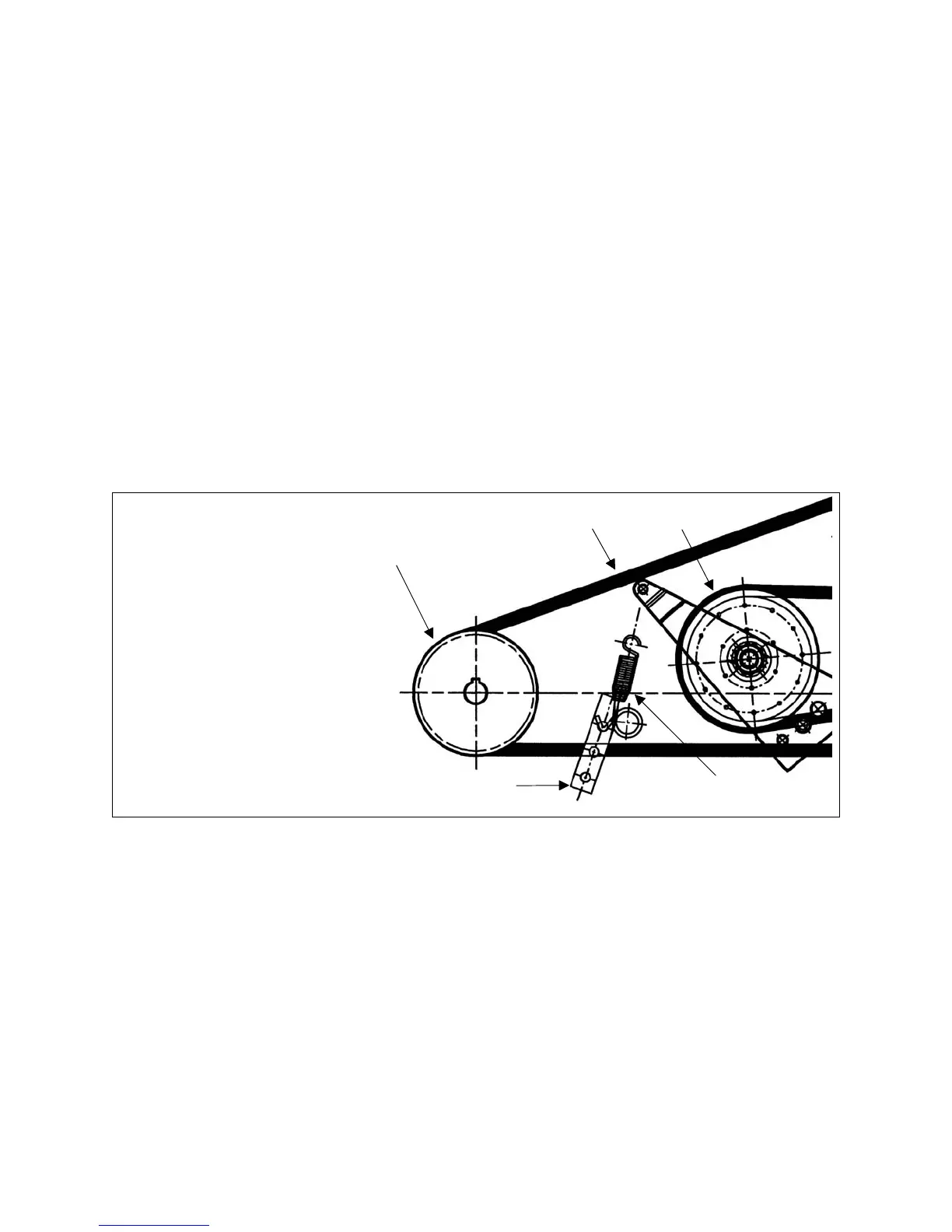

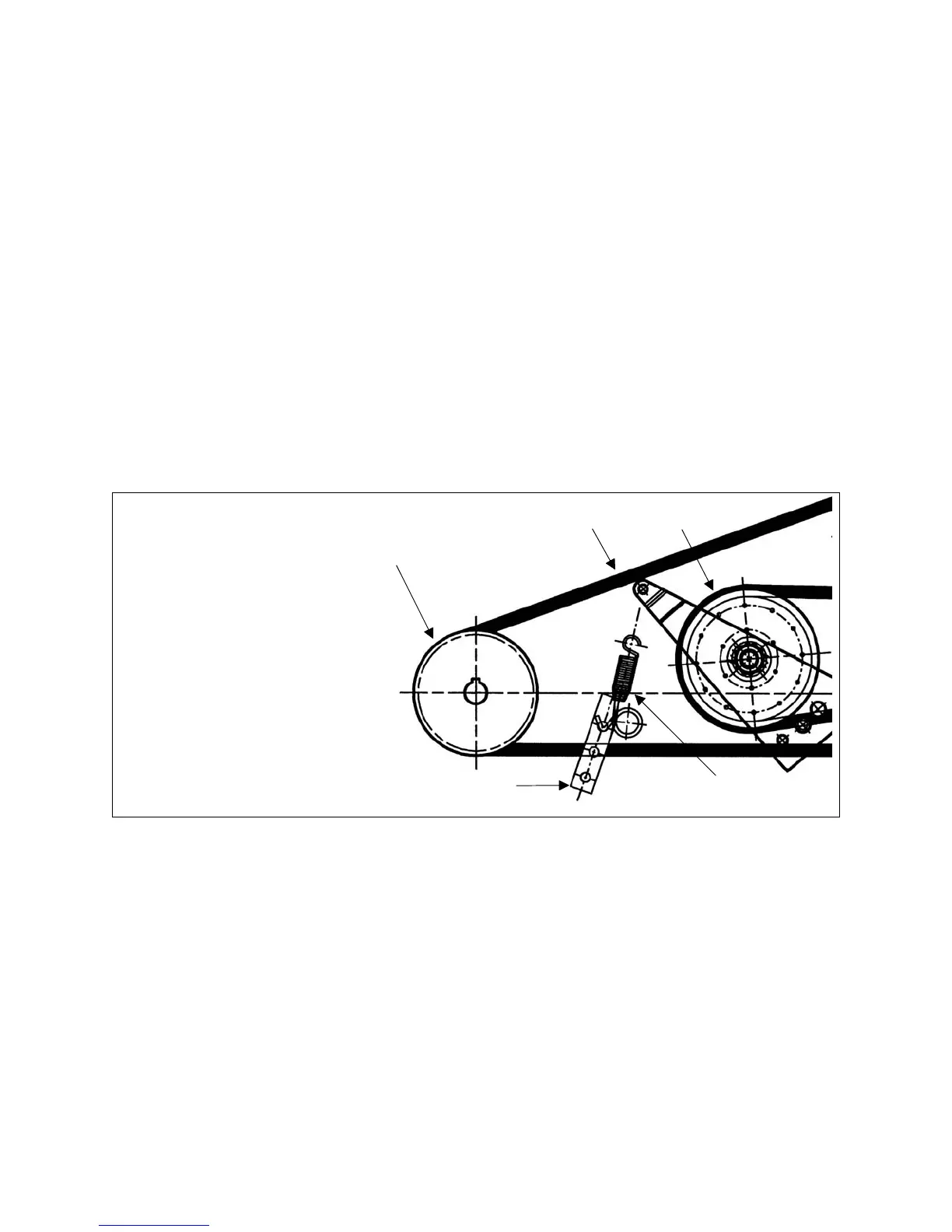

Belt tension control

1. Check the main drive belt by applying a force of 3-4 lb. pushing against the belt

halfway between the centrifugal clutch and the center spindle pulley. The belt

deflection should be between

1

/

8

”-

1

/

4

”.

2. Check the secondary belt tension by applying a force of 12-15 lb. pushing against

the belt halfway between the pulleys. The belt deflection should be between

5

/

16

”-

3

/

8

”.

Belt tension adjustment

1. If the main drive belt deflects more than

1

/

4

”, tighten the belt by loosening the four

engine nuts and turning the adjustment bolt clockwise until the belt is within the

specified range. Then re-tighten the four engine nuts.

2. The secondary belt has an automatic belt tensioner. The tension is created by a

spring connecting a tensioner pulley to a fixed hitch plate with 3 positions (see fig.

9). Upon delivery, the spring is located in the first position. When the belt stretches

after use, adjust the tension by relocating the spring in the other two holes. If the belt

has stretched to the point that the belt is not tight enough even in the last hole, then

it is necessary to replace the belt.

4.05 - Belts Replacement

If the belts have stretched or damaged to the point where the proper tension cannot be

obtained they must be changed.

To replace the belts (see #4 & 8, fig. 10) do the following:

1. Remove belt shield. Clean foreign material from the mower deck and belt area.

2. Loosen the four engine nuts.

3. Loosen the belt tensioner bolt.

4. Loosen rear nuts holding central plate (do not remove them).

5. Remove front nuts holding central plate.

6. Release spring tensioner to loosen secondary belt.

7. Lift the front of the central plate and remove old belts.

MAINTENANCE 23 BEFCO

C

YCLONE OPERATOR’S MANUAL

1

2

3

4

5

Fig. 9 - Secondary belt positioning.

1. tensioner

2. secondary belt

3. side pulley

4. spring

5. hitch plate

Loading...

Loading...