12

PRESSURE SENSOR, COVER,

AND GASKET REPLACEMENT

If a pressure sensor has been identified as faulty or

damaged, it must be replaced. (A service kit is available

from R.H. Sheppard.) Once the faulty or damaged

pressure sensor is removed, follow the steps below for the

installation of the new sensor.

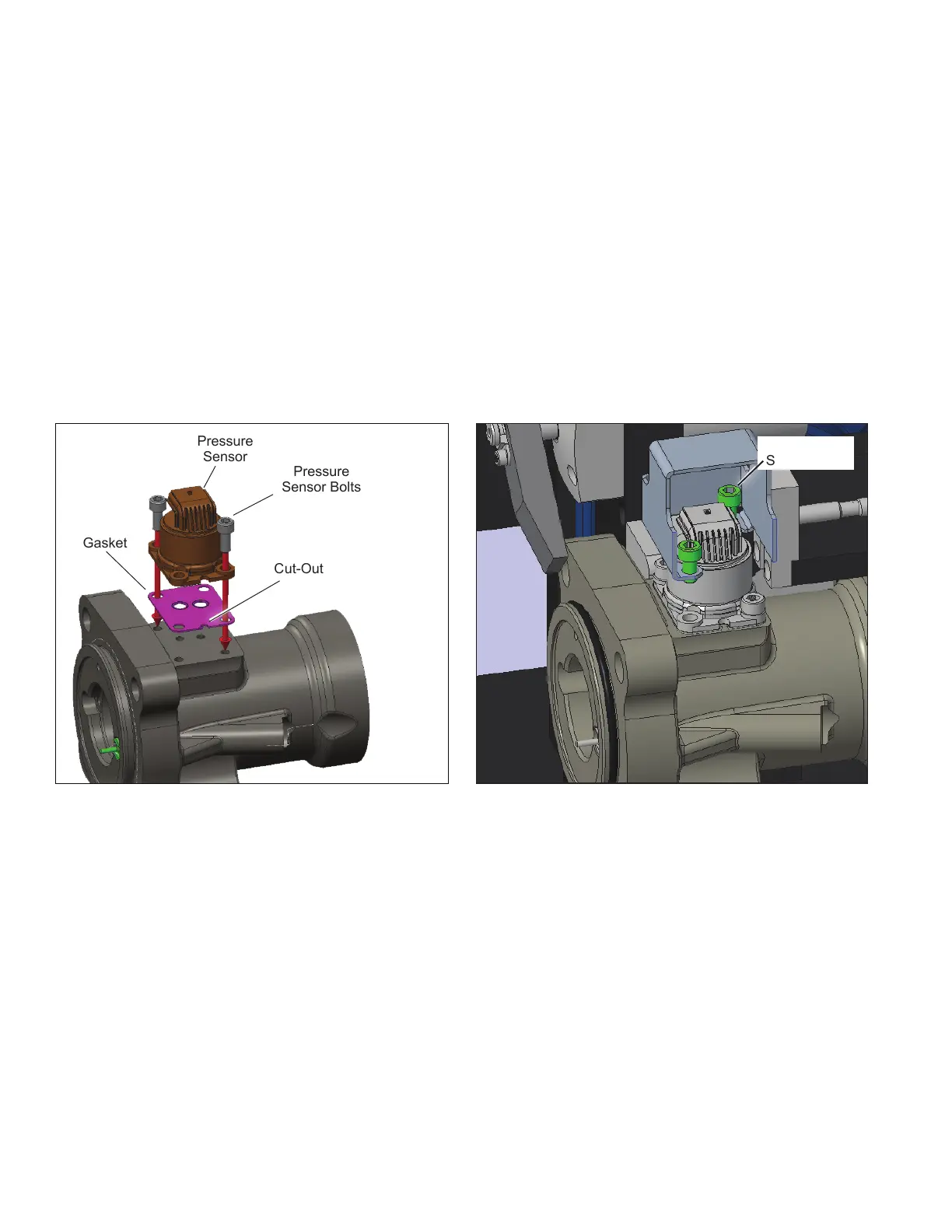

1. Align the gasket and pressure sensor with the half circle

cut-out in each part. See Figure 10.

2. Align the pressure sensor and gasket on the bearing

cap. See Figure 10.

3. Hand start and torque the front right, and back left

pressure sensor bolts to 13-16 ft-lb (17.6-21.7 Nm) with

the 5 mm hex (Allen

®

) bit. See Figure 10.

Figure 10 – Pressure Sensor and Gasket Figure 11 – Bolt Installation

Gasket

Pressure

Sensor

Pressure

Sensor Bolts

Cut-Out

Pressure

Sensor Bolts

Magnetic Torque

Overlay Steering

Gear

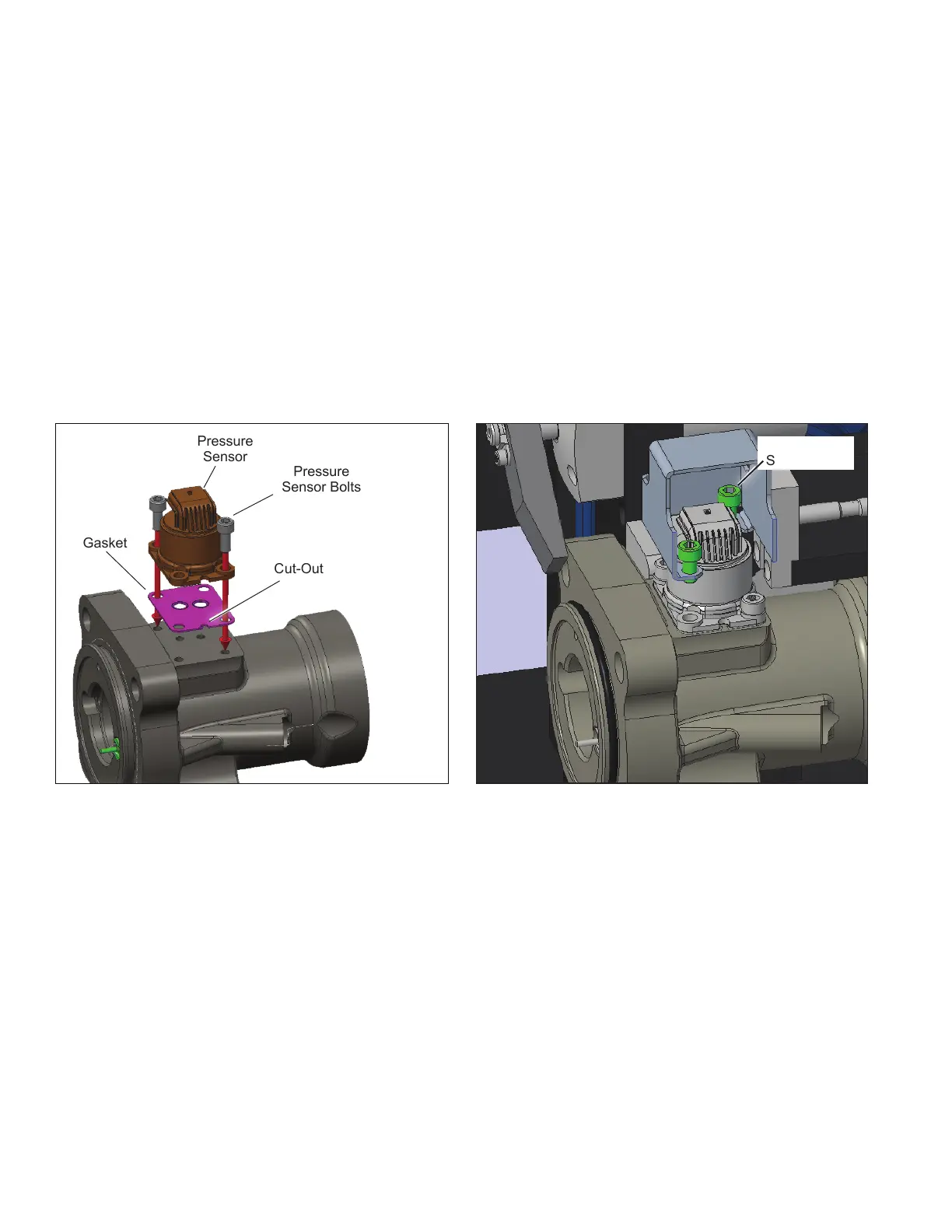

4. Remove the alignment xture (if used) and install the

pressure sensor cover by aligning the bottom tabs with

the open bolt holes. See Figure 11.

5. Hand start and torque the front left and back right bolts

to 13-16 ft-lb (17.6-21.7 Nm) through the tabs of the

pressure sensor cover with the 5 mm hex (Allen) bit.

See Figure 11.

MAGNETIC TORQUE OVERLAY

STEERING GEAR AND ECU

REPLACEMENT

To replace the steering gear or the ECU, please contact

the Bendix

®

Tech Team or Sheppard

®

Technical Support.

See page 13.

Loading...

Loading...