1

SD-03-4508

Bendix

®

SR-1

™

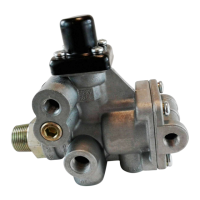

Spring Brake Valve

1/4 P.T.

RES. #1

1/4 P.T.

DELIVERY

1/4 P.T.

SUPPLY

PISTON SPRING

(14)

O-RING

(LARGE)

(18)

PISTON

SPRINGS (14)

FIGURE 1 - EXTERIOR VIEW

COVER (13)

1/4 P.T.

CONTROL

FIGURE 2 - SECTIONAL VIEW

DESCRIPTION:

The SR-1

™

spring brake valve is used in dual or “split” air

brake systems equipped with spring brake actuators. The

function of the SR-1

™

valve is to supply a specific, limited

hold-off pressure to the spring brakes, and in the event of

loss of No. 1 service air pressure, to modulate the spring

brakes through the use of the service brake valve.

The valve has four identified 1/4" N.P.T.F. ports and a

diaphragm protected exhaust port. Two 5/16" diameter holes

are provided in the integral mounting bracket of the valve

body. The SR-1

™

valve must be mounted with the exhaust

port down toward the road surface.

OPERATION - INITIAL AIR SYSTEM CHARGE

Upon initial charge, air from #1 & #2 service reservoirs flows

through the park control valve and enters the SR-1

™

valve

supply port. Air entering the supply port flows past inlet and

exhaust valve B to the underside of piston B and out the

delivery port of the SR-1

™

valve to the emergency air

connection at the spring brake actuator. Note that the springs

above piston B force it into contact with inlet and exhaust

valve B. In the position shown the exhaust is closed and the

inlet is open.

Air flowing from the No. 1 reservoir only enters the reservoir

port of the SR-1

™

valve. This air remains under piston A as

system pressure builds. With No. 1 reservoir pressure below

approximately 55 P.S.I. the spring above piston A forces it

into contact with inlet and exhaust valve A causing the

exhaust to seal and the inlet to open.

With air system pressure above approximately 55 P.S.I. in

No. 1 & 2 service reservoirs, piston A has moved against

the force of the spring above it, allowing the inlet of valve A

to close and opening the hollow exhaust passage through

piston A.

OPERATION - AIR BRAKE SYSTEM FULLY

CHARGED

When air pressure beneath piston B is approximately 95*

P.S.I., piston B rises slightly, against the force of the springs

above it, allowing the inlet of valve B to close. The exhaust

through valve B remains closed. The closing of the inlet

portion of valve B retains approximately 95* P.S.I. in the

hold- off cavity of the spring brake actuators while allowing

full air system pressure to build elsewhere.

*Note: Other spring brake hold-off pressures are supplied

according to the vehicle manufacturer’s

specifications. 95 P.S.I. was chosen only for the

purpose of explanation.

PISTON (15)

PISTON O-RINGS

(16)

VALVE (12)

VALVE SPRING (11)

VALVE STOP (10)

O-RING (9)

CAP NUT

(8)

PISTON (17)

O-RING

(SMALL) (19)

BODY

CHECK

VALVE SPRING (2)

PIPE PLUG

(1)

CHECK

VALVE (4)

EXHAUST

COVER (5)

DIAPHRAGM

(6)

INLET &

EXHAUST

VALVE (7)

Loading...

Loading...