2

2. Reconnect all air lines and plugs to the modulator-valve

assembly. Make certain that no thread sealing material

enters the valve. All air lines and fi ttings should be checked

for leaks prior to returning the vehicle to service.

3. Reconnect the ECU and sensor electrical connectors to

the unit. Slide the cover locking tab to gain access to the

internal connections. Apply a moderate amount of non-

conductive electrical grease to each connector pin before

reconnecting.

4. Install the new harness, starting at the ECU and properly

secure the harness every 18 inches to the power connector

location. Replace and lock the cover.

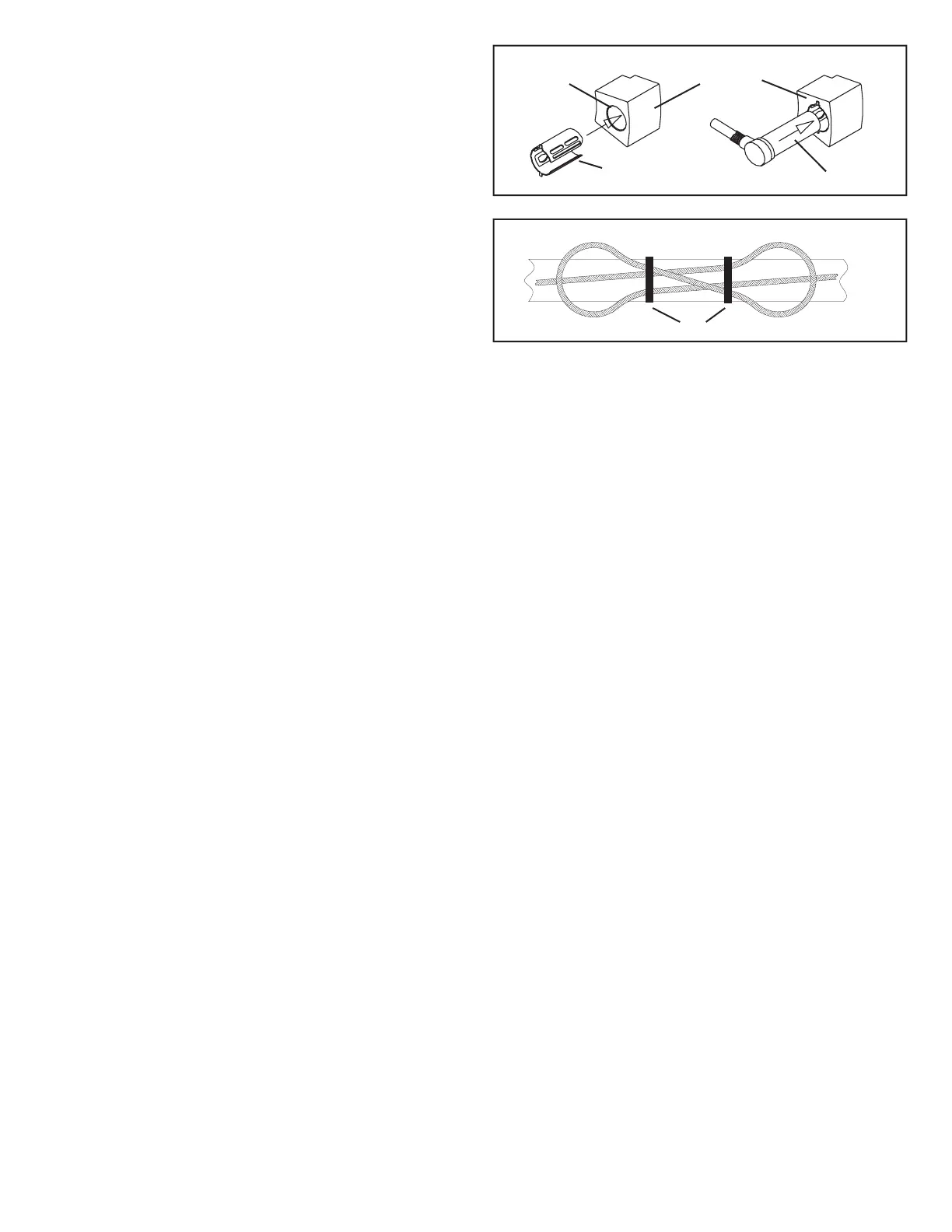

5. Where the harness length is more than needed, reroute

harness, or tie extra harness as shown in Figure 3.

6. The new controller may need to be reconfigured

for proper operation. See the Service Data sheet

SD-13-4767 included in the kit for more details. Leakage

and Operational Tests must be performed before returning

the vehicle to service.

LEAKAGE AND OPERATIONAL TESTS

1. Before performing leak tests, block the wheels.

2. Fully charge the air brake system and verify proper brake

adjustment.

3. Make several trailer brake applications and check for

prompt application and release at each wheel.

4. Check the modulator-valve body and all air hose fi ttings

for leakage by spraying each area with a soap solution:

- Check the ABS solenoid body with the trailer service

brakes fully applied. If leakage is excessive, replace the

entire ABS module. A single 1” bubble within 3 seconds

is permitted.

- Check the relay exhaust port and the area around the

retaining ring with the trailer service brakes released. A

single 1” bubble within 3 seconds is permitted.

- Check the relay exhaust port and the area around the

retaining ring with the trailer service brakes fully applied.

A single 1” bubble within 3 seconds is permitted.

If excessive leakage is detected at the relay exhaust

port, perform the following test before replacing the ABS

module:

Apply the trailer spring brakes. Recheck for leakage

around the exhaust port. If the exhaust port stops leaking,

this indicates a leak between the emergency and service

sides of the spring brake chamber. However, if the

relay exhaust port continues to leak, replace the entire

modulator-valve.

5. Apply power and monitor the controller power-up sequence

to verify proper system operation. The warning lamp

should come on for approx 2.5 sconds and then go out.

6. Calibrate and set odometer parameters if necessary using

a diagnostic tool.

7. Where a test track is available, test the ABS function by

making an abrupt stop from a vehicle speed of about 20

MPH to check for proper function. The wheels should not

enter a prolonged lock condition and ABS function should

be audible. It is the responsibility of the technician to

perform this test in a safe location.

ABS WIRING

The Bendix pigtail wiring harness and connectors are weather

resistant and sealed at the connector interface.

TROUBLESHOOTING

Fault information can be retrieved from the controller by using

blink code diagnostics shown on the yellow label included

in the kit, or a diagnostic tool. See the Service Data sheet

SD-13-4767 included in the kit for more details.

GENERAL MAINTENANCE PRECAUTIONS

WARNING! PLEASE READ AND FOLLOW THESE

INSTRUCTIONS TO AVOID PERSONAL INJURY OR

DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking

brakes, and always block the wheels. Always wear

safety glasses.

2. Stop the engine and remove ignition key when working

under or around the vehicle. When working in the

engine compartment, the engine should be shut

off and the ignition key should be removed. Where

circumstances require that the engine be in operation,

EXTREME CAUTION should be used to prevent

personal injury resulting from contact with moving,

rotating, leaking, heated or electrically charged

components.

Bundle Extra Wire

Length

Tie Wrap

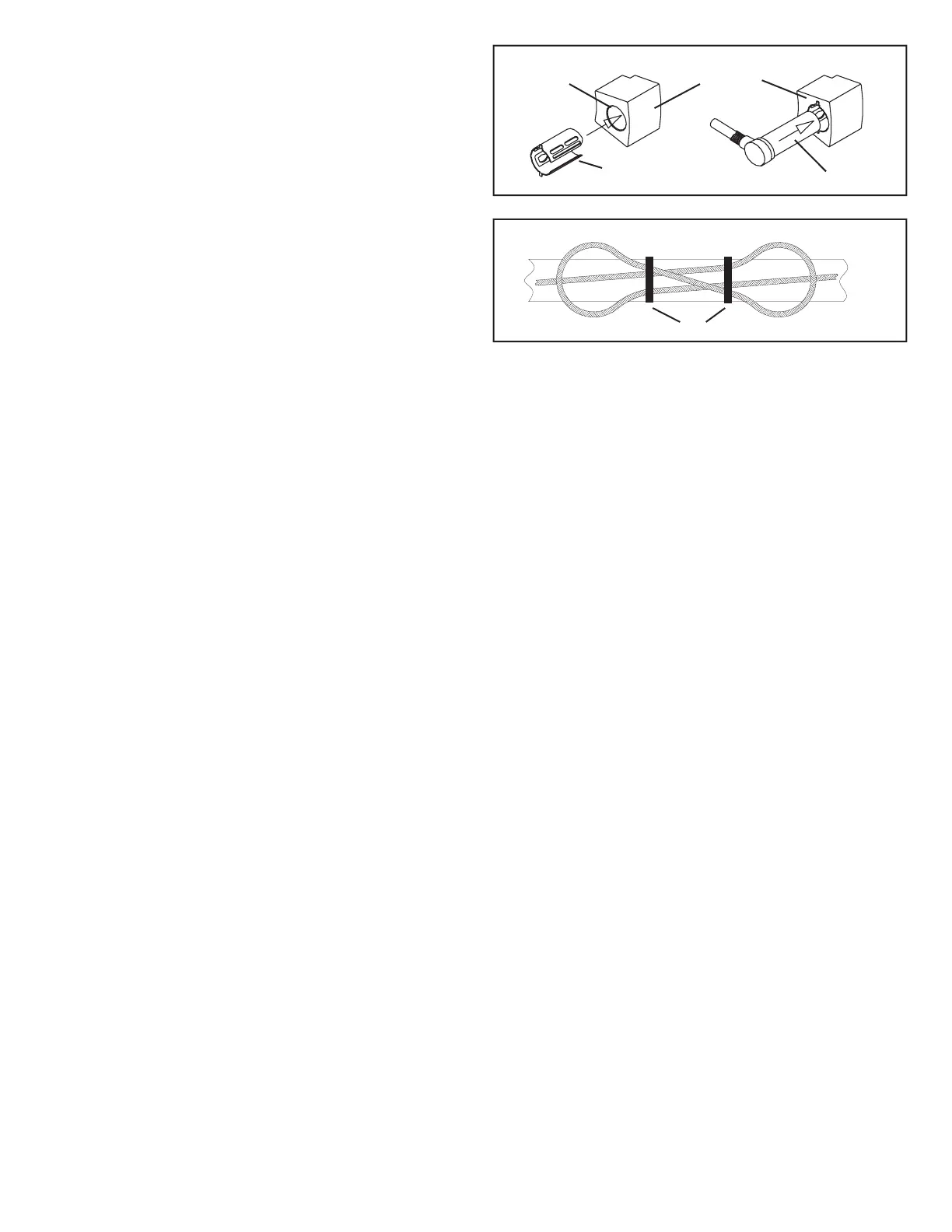

Wheel Speed Sensor

Sensor Clip

Block Bore

Speed Sensor

Mounting Block

FIGURE 3 - BUNDLING EXTRA WIRE LENGTH

FIGURE 2 - SENSOR CLIP AND SENSOR INSTALLATION

Loading...

Loading...