24

• To prevent damage to the column control panels,

avoid touching the outside and inside of the box panel

with sharp objects, striking the panel with a hard object,

the use of abrasives or using excessive force when

pressing the ergonomic push-button controls. In the

event that any of the components stop working correctly,

they can be replaced. The main system components of

this lift are standard off-the shelf brands rather than

proprietary printed circuit boards or controls which can

be very expensive to service or replace.

Lubrication

• Raise the lift and Park on the top most safety

position.

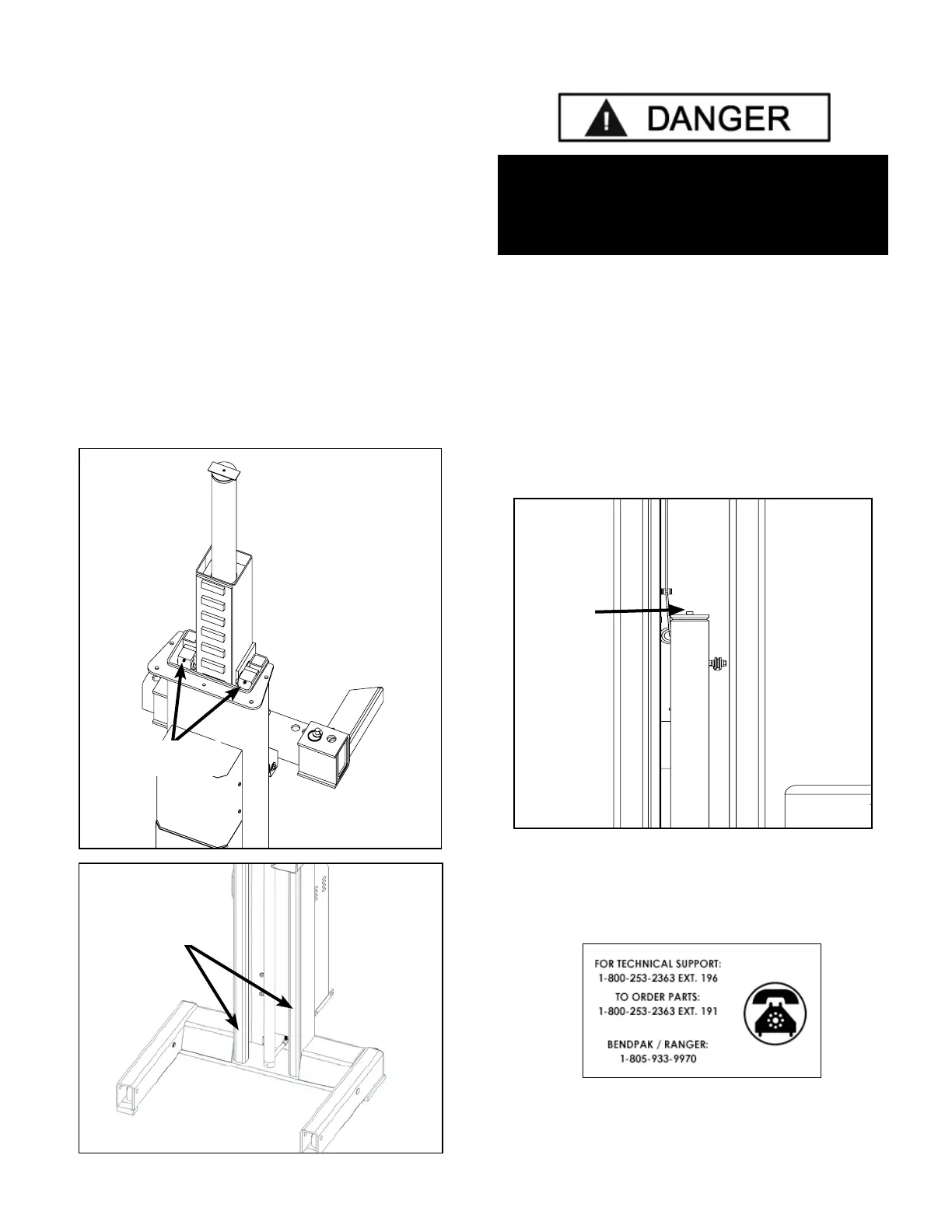

• Through the top and bottom of each Column, apply

a light coat of grease on the frontal face and internal

face of the Column Rails. See Figures A & B below.

Column Rails

Brass Sliders

Fig. A

Fig. B

Bleeding

1. After electrical power is connected and oil reservoirs

are full, press “UP” button to raise lift.

2. Continue raising until the fork arms are positioned

approximately 36” above oor level.

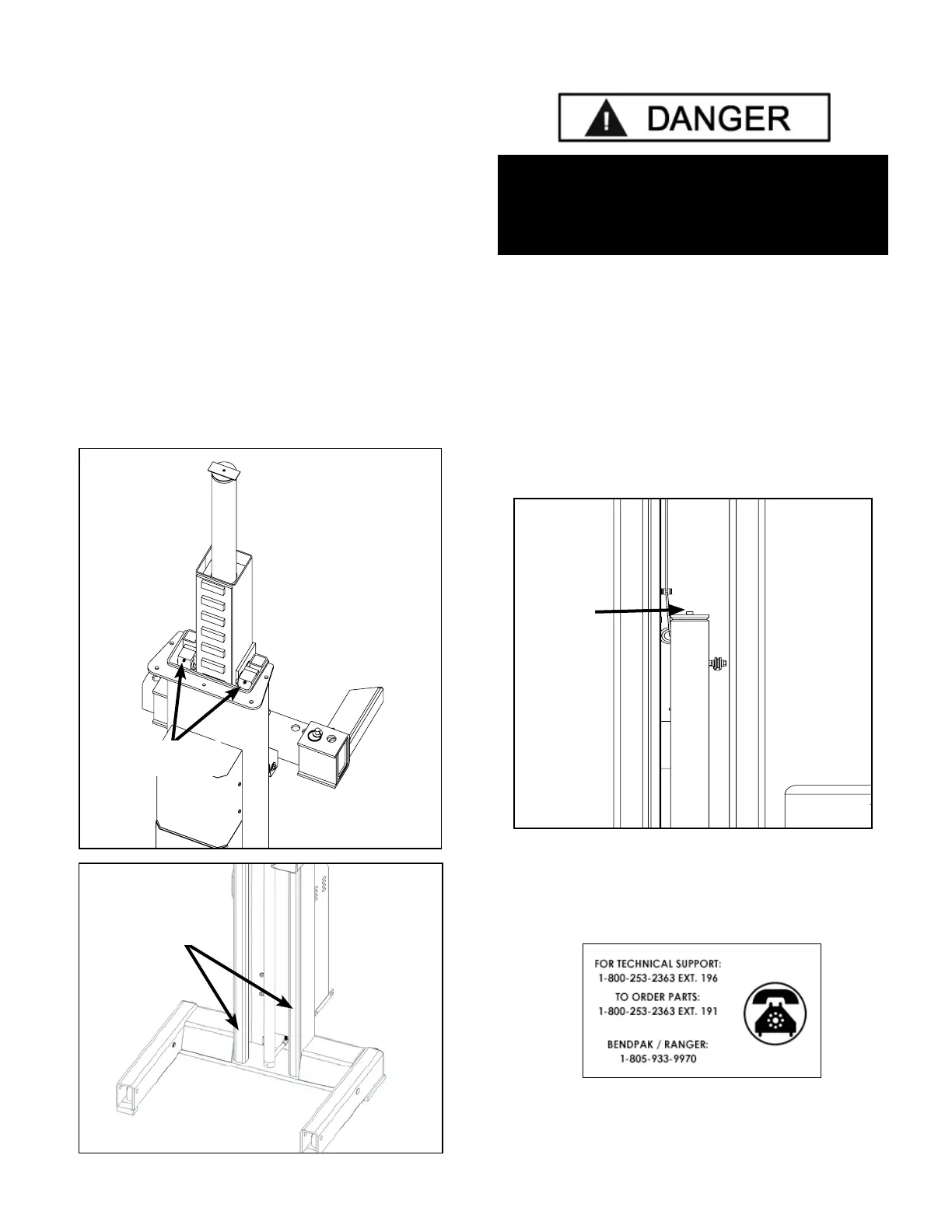

3. Slowly loosen the BLEED SCREWS, one by one,

located at the top of each cylinder to bleed trapped air.

DO NOT completely remove bleed screws. Re-tighten

after trapped air has escaped. (See Figure below).

4. Lower the lift completely. Wait ve minutes and

repeat bleeding process one additional time.

THE LIFT WILL MOVE DOWN WHEN BLEEDING.

MAKE SURE ALL EQUIPMENT, PERSONNEL,

HANDS AND FEET ARE CLEAR BEFORE

PERFORMING THE CYLINDERS BLEEDING.

Cylinder

Bleed

Screw

DO NOT

completely

remove

Bleed Screw.

One full turn

should purge

trapped air.

Loading...

Loading...