TECHNICAL DATA

Contol unit supply

24 Vdc

Power supply

230 Vac 50/60 Hz or 115Vac 50/60Hz according to the version

Output supply

1/2 motor 24Vdc

Maximum motor current

5+5 A

Output supply accessories

24Vdc 500mA max.

Protection level

IP55

Operating temp.

-20°C / +50°C

Radio receiver

built in 433,92 MHz confgurabile (rolling-code or programmable + rolling-code)

Rolling code transmitters supported

64

BRAINY 24 CONTROL UNIT

AUTOSET FUNCTION

IMPORTANT: The control unit is equipped with the Autoset function to automatically set the main functioning values based on the

type of installation.

The AUTOSET function must be repeated at every function parameter change or upon change of automation conditions. See the

AUTO menu for further information.

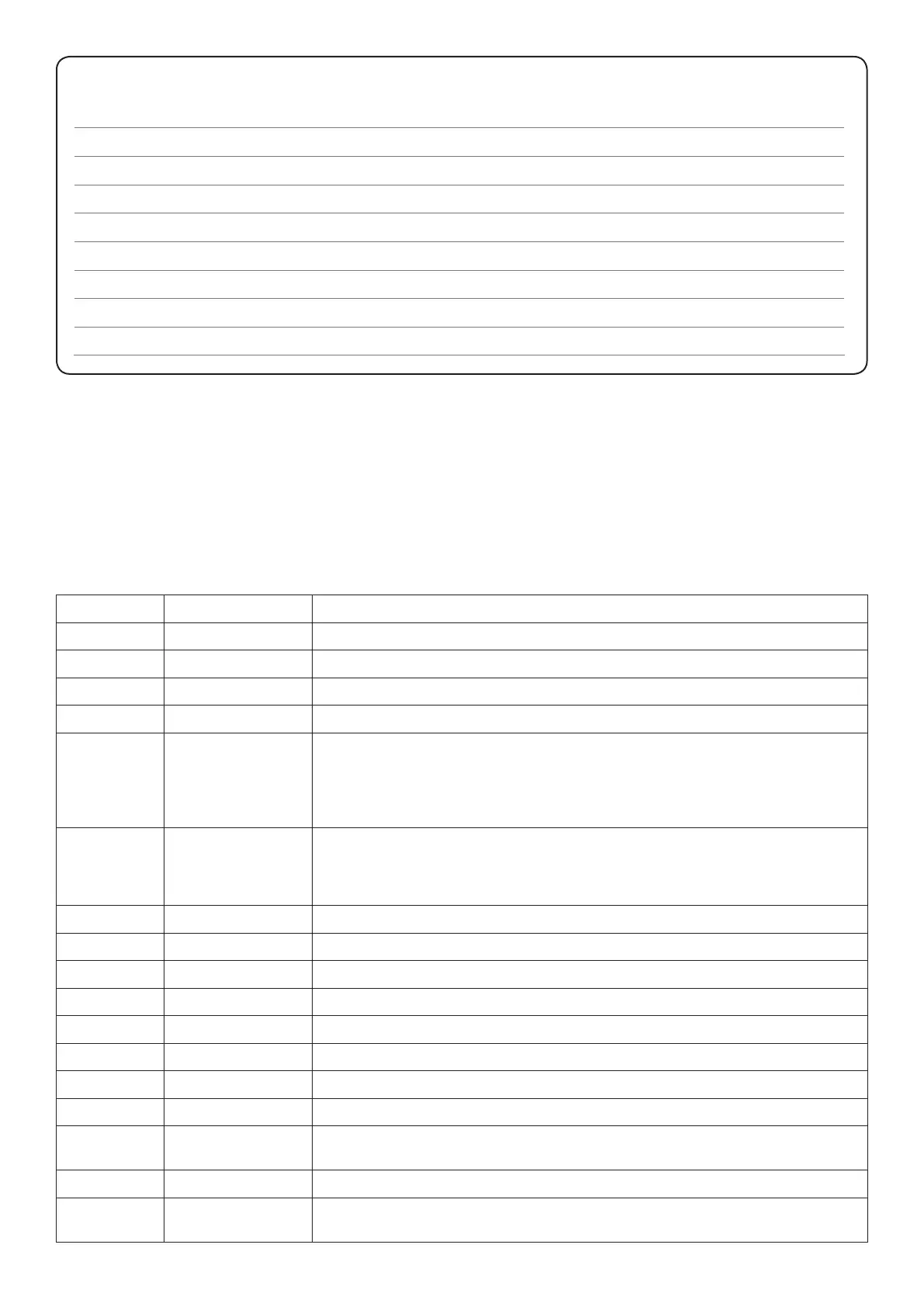

WIRE DIAGRAM

Wire connections shown in Fig. 1 are described hereunder:

Terminal No. Function Description

1-2 Motor 1 Connection, motor 1: 24VDC 5A max

3-4 Motor 2 Connection, motor 2: 24VDC 5A max

5-6 Flashing light Connection, flashing light 24VDC 15W max.

7-8 Lock Output, 12Vdc/10W power supply for electric lock (7:0V, 8:+12V)

9-10

SCA/

PHOTO TEST

Contact free from N.O. Voltage, may be configured as open gate indicator or photocell

test.

For use as “Open gate indicator” the TEST1 and TEST2 logics must be OFF

For use as photocell test it is sufficient to activate one or both TEST logics and connect

the photocells as indicated in Fig.3.

11-12 24 Vac/dc

Output, accessory power supply, 24VAC/0.5A max.

IMPORTANT: If the battery charger board is installed, the output (without mains power

connected) has a 24Vdc polarised voltage.

Make sure the devices are correctly connected (i.e. 11:+24Vdc / 12:-0Vdc).

13 COM/ENC+ Common for limit switch and all the command inlets or encoder power supply.

14 SWO1/ENC1 Motor 1 OPEN limit switch input (N.C. contact) or Motor 1 Encoder connection.

15 SWC1 Motor 1 CLOSE limit switch input, (N.C. Contact)

16 SWO2/ENC2 Motor 2 OPEN limit switch input, (N.C. Contact) or Motor 2 Encoder connection.

17 SWC2 Motor 2 CLOSE limit switch input, (N.C. Contact)

18 PHOT Input, photocell activated in both opening and closing phases

19 PHOT C Input, photocell activated in closing phase only (Normally closed contact)

20 STOP Input, STOP push-button (Normally closed contact)

21 OPEN

Input, OPEN push-button (Normally open contact).

It is possible to connect a timer for opening in time slots.

22 CLOSE Input, CLOSE push-button (Normally open contact)

23 PED

Pedestrian button input (N.O. Contact), controls the motor 1 opening, see TPED pa-

rameter.

Loading...

Loading...