BV200 Plasma Viscometer Mk2/3 Customer User

Manual

Issue 9

th

Sep 2020 - Rev 1.8 Page 21 of 53

If the second check is not validated the viscometer will either STOP or automatically 9.

RECALIBRATE, depending on the choice of configuration. The „STOP‟ (manual

calibration) option is recommended, since it allows the operator to investigate and carry

out possible local maintenance if required. To carry out a manual calibration insert the

following charged calibration tubes in the next available carriages:-

Red carriage for HIGH CALIBRATOR with cap OFF

Blue carriage for LOW CALIBRATOR with cap OFF

Green carriage for CHECK CALIBRATOR with cap OFF (Check cap off for

calibration only).

To initiate a manual calibration press „manual calibration‟ in the „maintenance menu‟

After testing the liquid, sample tubes should be removed from the conveyor. 10.

Remove any „empty‟ HIGH, LOW, and CHECK tubes. These can be identified by 11.

looking at the schematic display showing the distribution of all tubes that have been

tested. Empty tubes will have their symbol (e.g. C) flashing. In the barcode column on

the screen there is a number showing the number of dips taken from each calibration

tube (12 dips per tube for CHECK and 6 dips per tube for HIGH and LOW).

Reposition the CHECK tubes (12 dips per tube) to green holders on the left of the tube 12.

conveyor as the viscometer is loaded with patient samples.

Insert an empty HIGH tube in the red holder. This will update the viscometer tube 13.

location software as to the position of the red holder no 199 in the stage. The

viscometer can count and record the tube carrier numbers as the conveyor advances.

On completion of work select a „closedown clean‟ or insert a „stop flag‟. This will initiate 14.

a closedown clean which will drain the wash water from the valves and the fluid system.

5.3. To print a results report

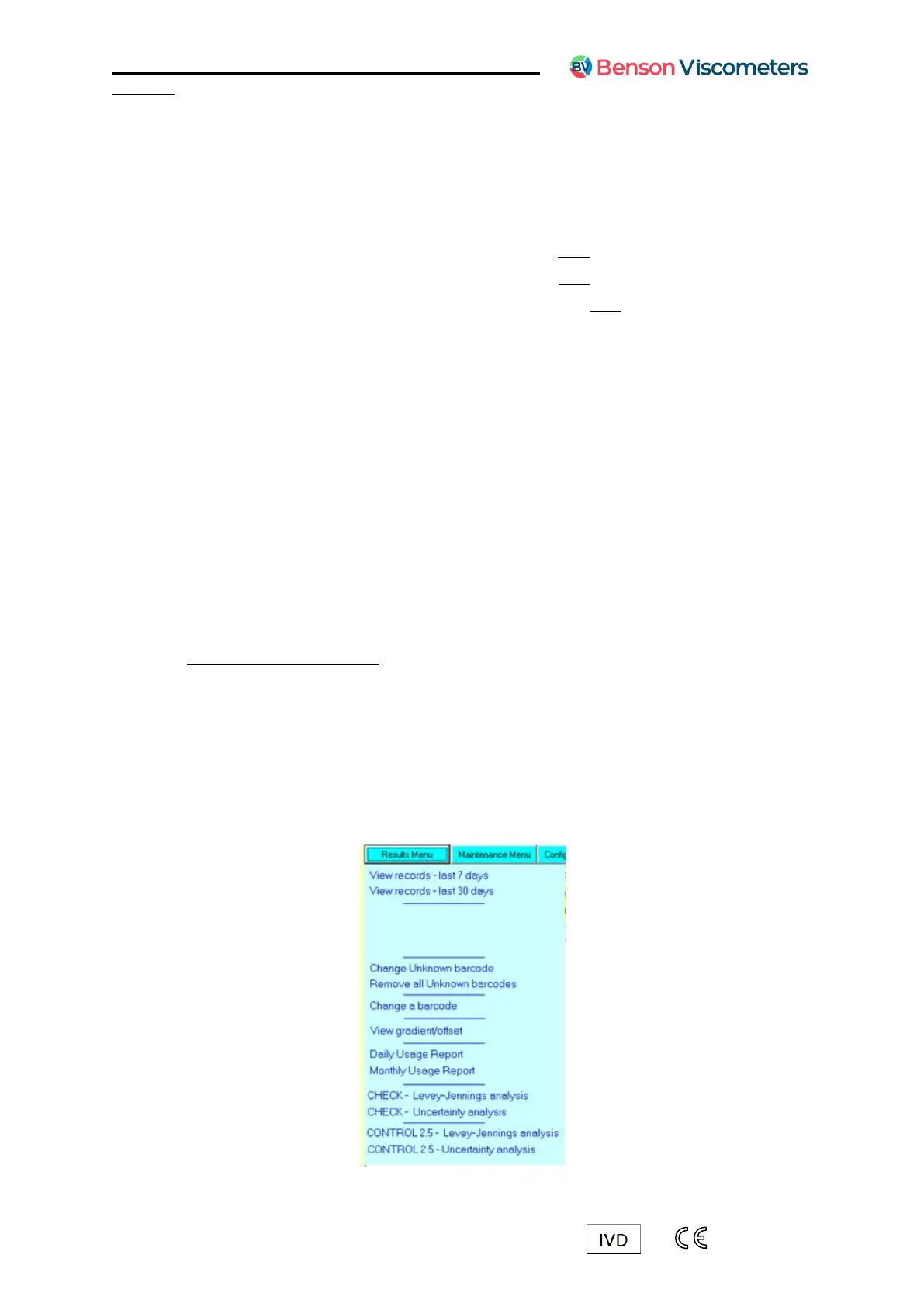

There are a number of reports available within the software such as; 1.

Results reports

Useage reports

Levey-Jennings analysis of CHECKS/CONTROLS

Uncertainty analysis of CHECKS/CONTROLS

These are found in the results menu of the software 2.

Loading...

Loading...