technology for your future

Automation

BFI

Installation

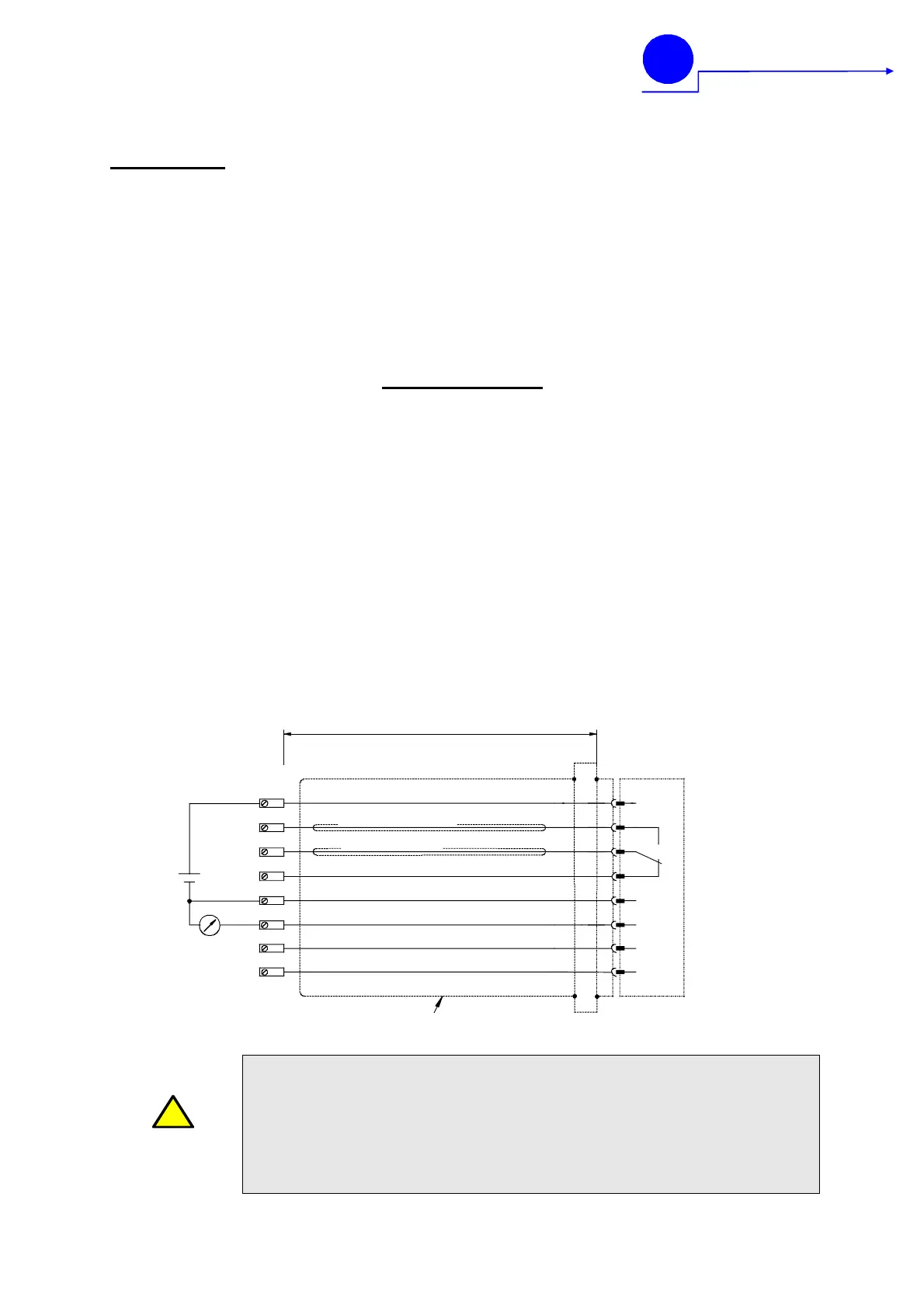

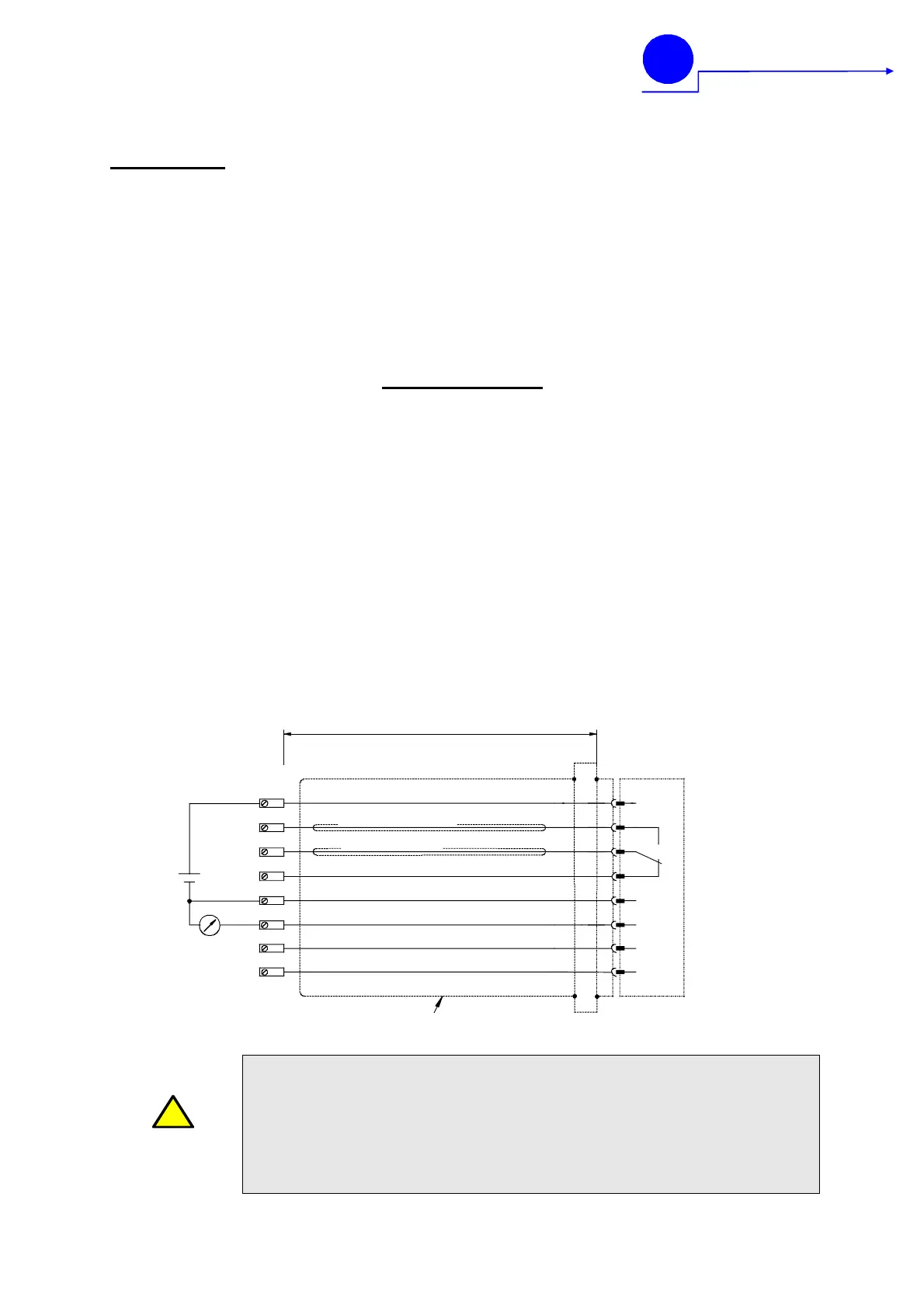

The pin assignment of the connector is shown in

the wiring diagram.

The output signal 0(4)-20mA for flame intensity is

not separated by the supply voltage, so the sig-

nal refers to the operating voltage measures. If

this should lead to problems, a corresponding

isolating transformer can be provided upon re-

quest. The burden of 250 ohms should always

not be exceeded.

The device is immediately ready for operation af-

ter switch-on of the supply voltage.

Wiring Diagram

Pin/Terminal Description colour code

BFI special cable KW6

1 Flame relay: Root white

2 Flame relay: Contact flame ON brown

3 Flame relay: Contact flame OFF pink

4 power supply: +24 V DC green

5 power supply: 0V (GND) yellow

6 current output 0(4)-20 mA grey

7 switch over canal 1 / canal 2 – 24V DC red

8 failure indication output +24V DC blue

!

CAUTION

CAUTION: In order to guarantee a proper operation the compact

flame controller must be tested several times at all conditions. The

burner has to be started and stopped several times (the flame relay

must always interrupt reliably with no flame on). Carry out these tests

while different neighbour burners are started and stopped as well as

on different boiler loads. This is a vital assumption for a proper and

reliable operation.

sensitivity switch over time I / II

7

red

7

failure indication output

8

blue

8

power supply +24V DC

flame relay "flame ON"

flame relay "root"

flame relay "flame OFF"

outer braided shield

current output 0/4 - 20mA

4

2

1

3

4

2

6

green

brown

white

pink

grey

CFC

2000

6

power supply 0V (GND)

5

yellow

5

1

3

BFI-special cable KW5

Loading...

Loading...