INSTALLATION MANUAL

1) GENERAL OUTLINE

The BOTTICELLI 800 U system is suitable for motorising sectional doors (g. C),

protruding fully retracting spring-operated overhead doors (g. B) and counter-

weight overhead doors provided with an appropriate towing arm (g. D). The

overhead door must not be higher than 3 metres. Its easy installation allows fast

tting without needing the door to be modied. The irreversible gearmotor keeps

the door locked in the closing position.

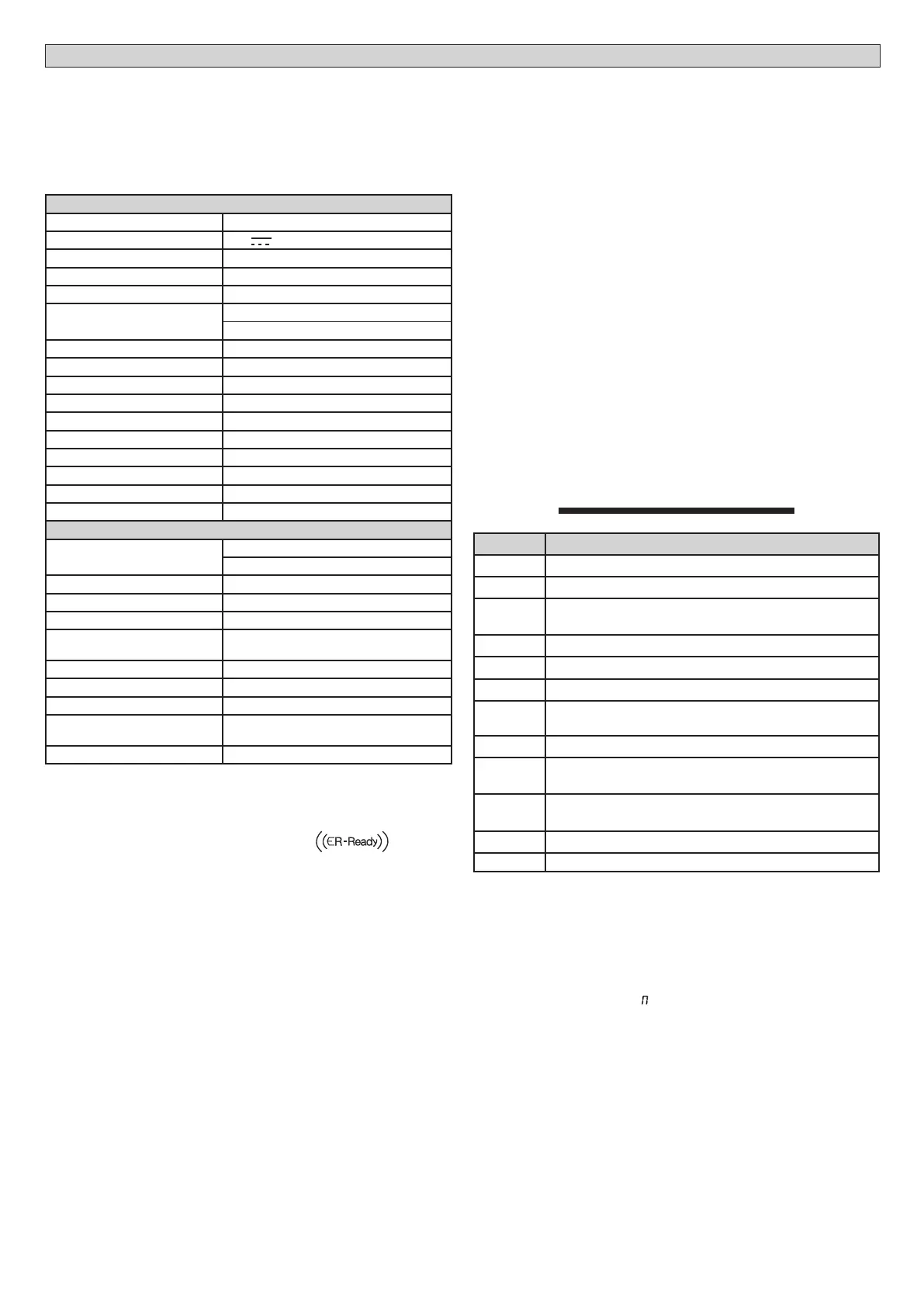

2) TECHNICAL SPECIFICATIONS

ATTUATORE

Power supply 230V ~±10%, 50/60Hz single-phase (*)

Motor voltage 24V

Max. power absorbed from mains 180W

Lubrication permanent grease

Towing and pushing force 800 N

Working stroke

BINARIO L.=2900 working stroke=2400 mm (**)

BINARIO L.=3500 working stroke=3000 mm (***)

Average speed 5 m/min

Impact reaction integrated torque limiter on control panel

Manoeuvres in 24 hours 20

Limit switch Electronic with ENCODER

Courtesy light BFT model courtesy LED lamp

Working temperature -15°C / +60°C

Degree of protection IPX0

Motor head weight 5 kg

Noise level <70dB(A)

Dimensions see g.1

CONTROL PANEL

Supply to accessories

24V~ (180mA max)

24Vsafe (180mA max)

Torque limiter setting on closing and opening

Blinker connection 24V~ max 25W

Service light switching-on time 90s

Incorporated rolling-code radio

receiver

Frequency 433.92 MHz

Coding rolling-code algorithm

No. combinations 4 milliard

Antenna impedance 50 Ohm (RG58)

Max no. radio controls to be

memorised

63

Fuses see gure T

(*) Available in all mains voltages.

(**)By turning the motor head by 90° (Fig.N) the useful stroke will be 2580 mm.

(***)By turning the motor head by 90° (Fig.N) the useful stroke will be 3180 mm.

Usable transmitter versions:

All ROLLING CODE transmitters compatible with

3)

ELECTRICAL INSTALLATION SET-UP

Fig.A

Arrange for the connections of accessories and safety and control devices to

reach the motor unit, keeping the mains voltage connections clearly separate

from the extra low safety voltage connections (24V).

Proceed to connection following the indications given in the wiring diagram.

The cables for connecting the accessories must be protected by a raceway (g.

K ref. 5C1).

4) ACTUATOR INSTALLATION

4.1) Preliminary checks

• Check that the door is balanced.

• Check that the door slides smoothly along its entire travel.

• If the door has not been newly installed, check the wear condition of all its

components.

• Repair or replace faulty or worn parts.

• The automation reliability and safety are directly inuenced by the state of

the door structure.

• Before tting the motor, remove any superuous ropes or chains and disable

any unnecessary appliances.

4.2) FITTING

1) Remove the existing locking bolt from the cremone bolt of the door.

2) Fit the metal wall bracket to the track-holder bracket using the screws sup-

plied as standard (Fig.E1). The screws must not be tightened, so that the

bracket can be rotated.

3) In order for the track to be correctly xed, mark the mid-point of the door,

position the BIN onto the ceiling and mark the holes (Fig.F).

Make sure that the distance between the track and the door panel is com-

prised between 108 and 166 mm (see Fig.G). The table in Fig. H gives the

various combinations for fastening the bracket to the overhead door.

4) Drill the ceiling using a D.10 bit, with reference to the markings made previ-

ously, and insert the plugs. Fig. I.

5) Secure the track at the base, g.J (1-2), K (3-4-5).

6) With the help of an adequate support, lift the entire motor, screw the screws

onto the track-holding bracket without xing them to the door frame (Fig.

L1) or, if the height allows it, t the bracket to the masonry lintel by means

of plugs (Fig.L2).

7) Rest the motor onto the oor (taking care not to damage it) and x the

articulated bracket to the door frame or to the ceiling.

8) In the case where the motor is not directly xed to the ceiling, t the brack-

ets as shown in Fig.M, after marking and drilling the holes with reference to

the brackets.

9) In the case where the track is turned by 90° with respect to the motor head,

use the reference template in Fig. N1 to cut out the guard, keeping to the

measurements indicated. For track tting to the ceiling, see Fig.F (for tracks

tted lower, see Fig.E).

10) In the case where the track is made in two halves, see Fig.O; for the dierent

types of xing methods, see the previous gures.

11)

Release the carriage and x the anchoring brackets to the door panel (Fig.H).

The distance allowed between track and sectional door is 108 to 166 mm.

In case of greater distance, it is necessary to use the brackets and lower the

motor; in case of shorter distance, it is necessary to shorten the towing plate.

12) Stick the adhesive labels supplied next to the dangerous points (Fig. Q).

5) CHAIN TIGHTENER ADJUSTMENT (BOTTICELLI 800 U)

The operator supplied is already calibrated and inspected. Should the chain ten-

sion need to be adjusted, proceed as shown in g. R.

WARNING: the anti-tear rubber element must never be completely com-

pressed. Scrupulously check that the rubber does not become totally com-

pressed during operation.

6) MANUAL RELEASE (See USER GUIDE -FIG.1-).

----------------------------------------------------------

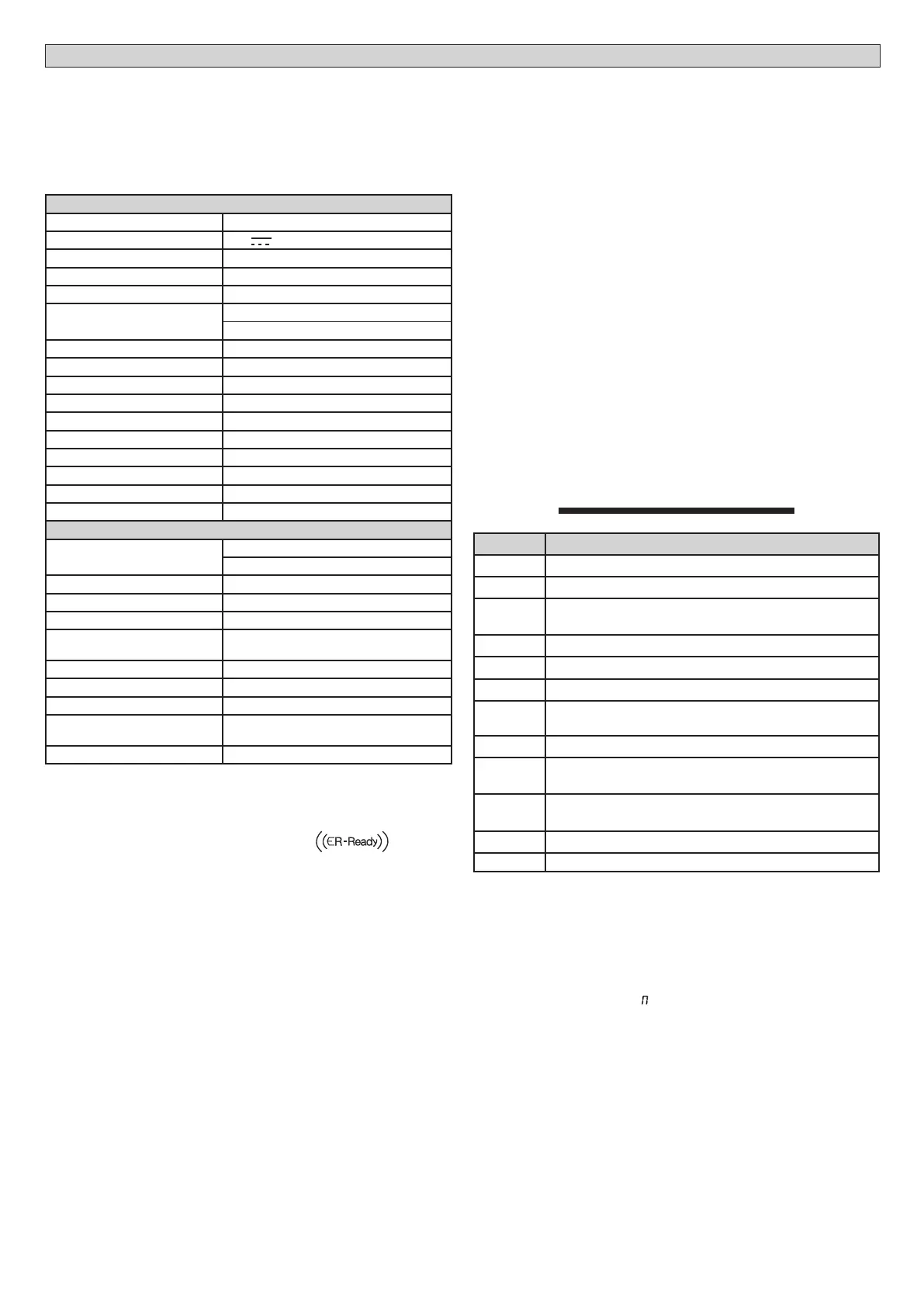

7) TERMINAL BOARD CONNECTIONS (FIG.T)

TERMINAL DESCRIPTION

JP2

transformer wiring

JP10

motor wiring

1-2

Antenna input for integrated radio-receiver board

(1: BRAID. 2: SIGNAL)

3-4

IC1 input (N.O.)

3-5

STOP input (N.C.) If not used, leave the jumper inserted.

3-6

SAFE1 input (N.C.) If not used, leave the jumper inserted.

3-7

FAULT1 input (N.O.)

Test input for safety devices connected to SAFE 1.

8-9

24 V~ output for blinking light (25 W max)

10-11

24V~ 180mA max output – power supply for photocells or

other devices.

12-13

24V~ Vsafe 180mA max output – power supply for checking

photocell transmitters.

14-15

AUX 3 (N.O.) congurable output

16-17 Ingresso IC2 (N.O.)

8) SAFETY DEVICES

Note: only use receiving safety devices with free changeover contact.

8.1) TESTED DEVICES Fig. T1

8.2) CONNECTION OF 1 PAIR OF NONTESTED PHOTOCELLS Fig. T2

9 CALLING UP MENUS: FIG. 1

9.1) PARAMETERS MENU PARA PARAMETERS TABLE “A”

9.2) LOGIC MENU LOGIC LOGIC TABLE “B”

9.3) RADIO MENU radio RADIO TABLE “C”

- IMPORTANT NOTE: THE FIRST TRANSMITTER MEMORIZED MUST BE

IDENTIFIED BY ATTACHING THE KEY LABEL (MASTER).

In the event of manual programming, the rst transmitter assigns the RECEIVER’S

KEY CODE: this code is required to subsequently clone the radio transmitters.

The Clonix built-in on-board receiver also has a number of important advanced features:

• Cloning of master transmitter (rolling code or xed code).

• Cloning to replace transmitters already entered in receiver.

• Transmitter database management.

• Receiver community management.

To use these advanced features, refer to the universal handheld programmer’s

instructions and to the general receiver programming guide.

9.4 MENU DEFAULT default

Restores the controller’s DEFAULT factory settings. Following this reset, you will

need to run the AUTOSET function again.

14 - BOTTICELLI 800 U

D812779 00100_08

Loading...

Loading...