INSTALLATION MANUAL

12 - LUX BT 2B - LUX G BT 2B

D811702 00100_01

2) GENERAL INFORMATION

Strong, compact hydraulic piston, available in various versions depending on

TQFDJöD OFFETBOEöFMEPGVTF5IFSF BSFNPEFMTGFBUVSJOH IZESBVMJDMPDLJOH

BOEOPOMPDLJOHSFWFSTJCMFNPEFMTUIBUOFFEBTPMFOPJEMPDLUPLFFQUIFNJO

position.

0QFSBUJOHGPSDFJTBEKVTUFEXJUIFYUSFNFQSFDJTJPOCZNFBOTPGUIFDPOUSPMVOJUT

electronic control. Operation at the end of travel is adjusted electronically in the

control panel.

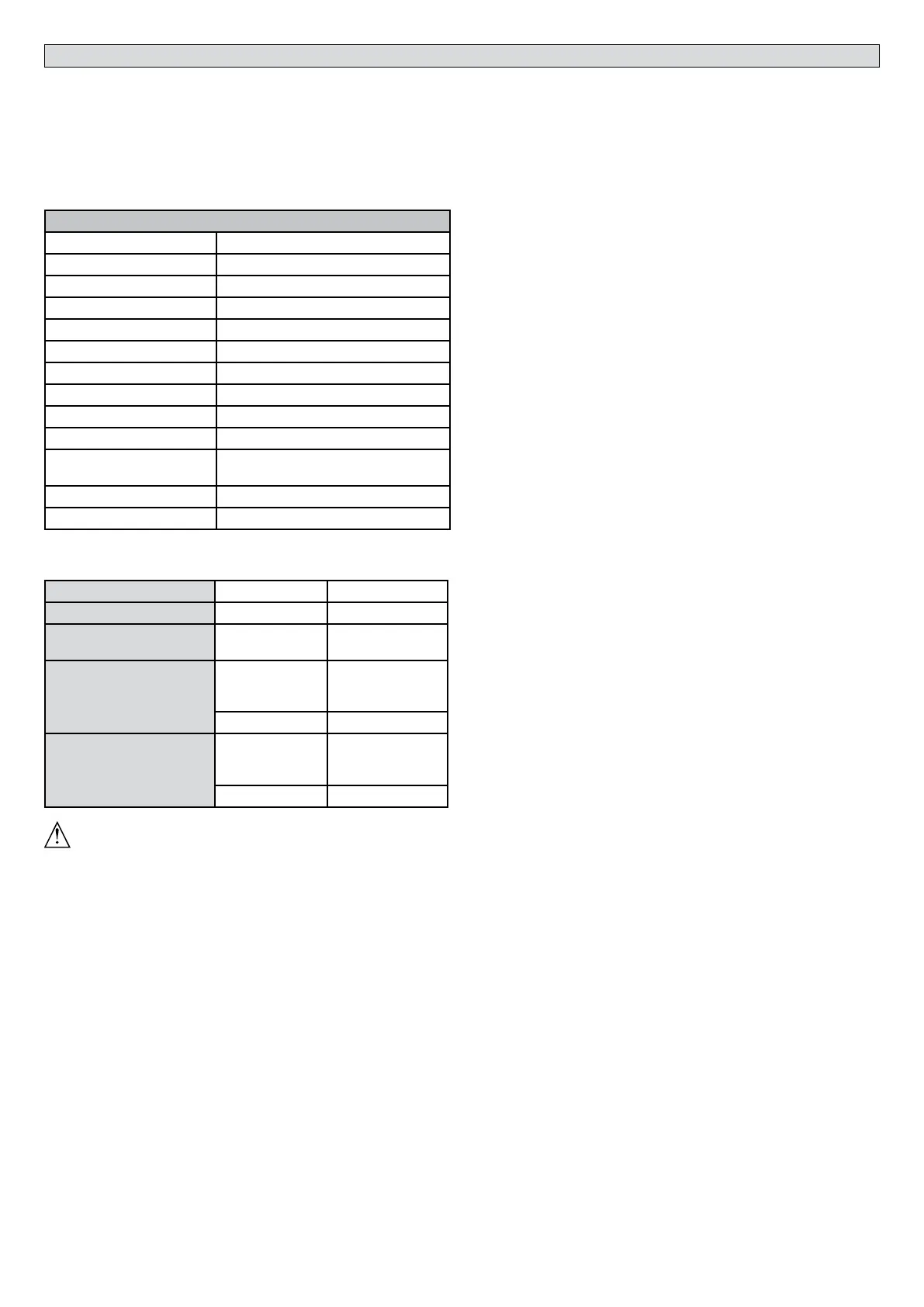

3) TECHNICAL SPECIFICATIONS

1PXFSTVQQMZ 24V

.BYQPXFSJOQVU 300W

.BYQSFTTVSF 30 bar

Pump delivery rate 1,2 l/min.

Operating force 3000 N

Pulling force 2600 N

Ambient temperature range - 20°C to 60°C

Impact reaction FMFDUSPOJDDMVUDIXJUIDPOUSPMQBOFM

Manual operation release key

Protection rating IP 55

Actuator weight LUX BT 2B: 8,4 kg

LUX G BT 2B: 9,3 kg

Overall dimensions Fig. Q

Oil *ESPMVY8JOUFS

4QFDJBMTVQQMZWPMUBHFTUPPSEFS

Table 1:

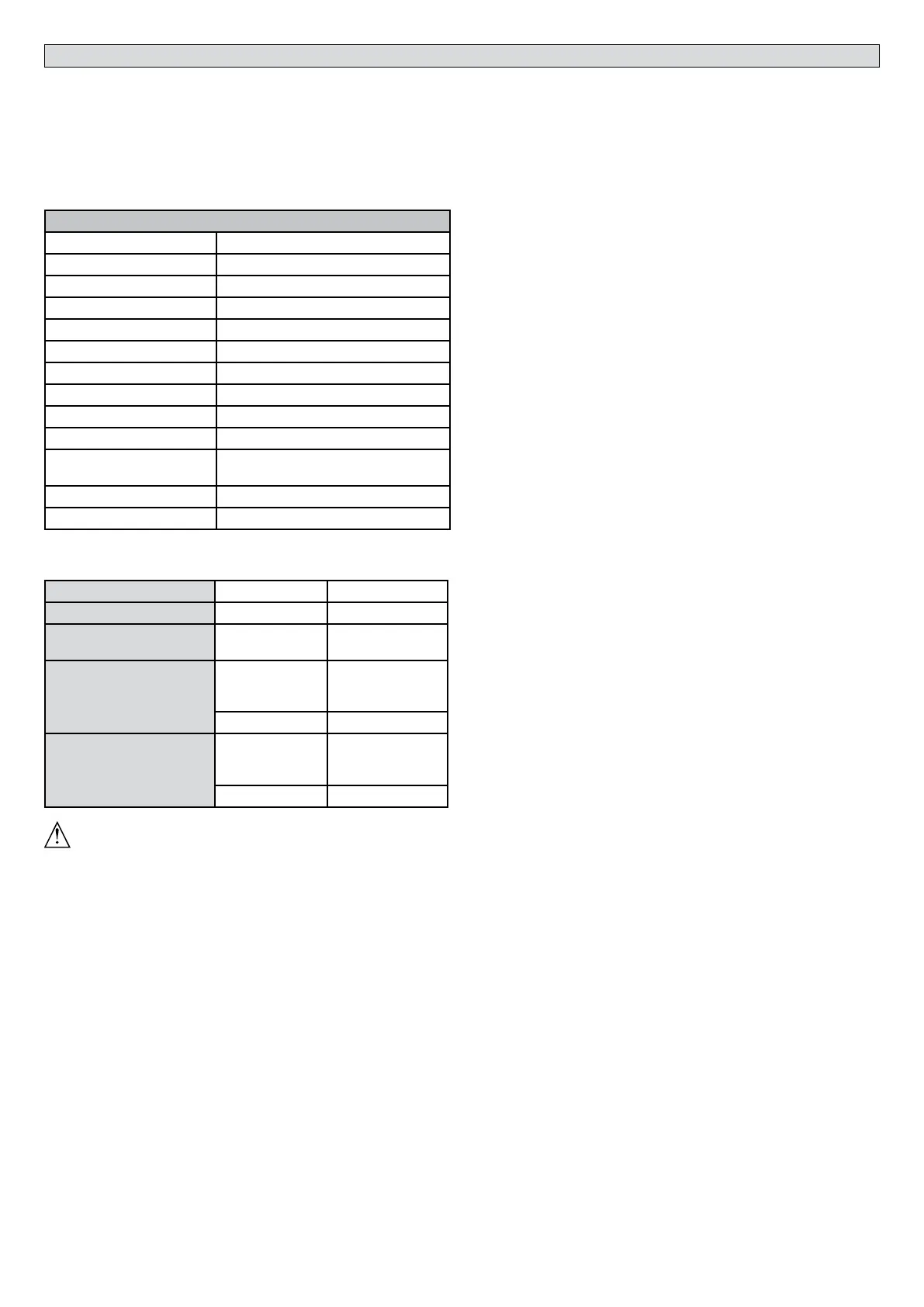

MOD. LUX BT 2B LUX G BT 2B

LOCKING TYPE Hydraulic Hydraulic

ACTUAL TRAVEL TIME 14 sec. 2 0 sec.

LEAF MAX.

(m)

(Kg)

2 5--2

300 300/800

TRAVEL mm

usable

total

270 392

290 412

WARNING: With leaves over 3 metres long, the solenoid lock must be

used and locking devices must be opened (Fig. M Ref. 2)

4) TUBE ARRANGEMENT Fig. A

5) PILLAR FASTENINGS INSTALLATION DISTANCES Fig. B

6) INSTALLATION DIAGRAM Fig. C

P rear bracket fastening to pillar

F front fork fastening leaf

a-b distances for determining bracket “P” fastening point

$WBMVFPGGBTUFOJOHDFOUSFUPDFOUSFEJTUBODFTFFFig. Q

D gate length

9EJTUBODFGSPNHBUFBYJTUPDPSOFSPGQJMMBS

;WBMVFBMXBZTHSFBUFSUIBONNC9

LH NBYXFJHIUPGMFBGTable 1

α° leaf opening angle

7) FASTENING OF FITTINGS TO PILLAR Fig. D

8) POWER CABLE Fig. E

9) ATTACHING MOTOR TO FASTENING ON PILLAR Fig. F

10) MAXIMUM TILT Fig. G

11) ENCODER ROD ASSEMBLY Fig. H

12) CORRECT INSTALLATION Fig. I

$PSSFDUJOTUBMMBUJPOFOUBJMTNBJOUBJOJOHBSPETUSPLFNBSHJOPGBQQSPYNN

to avoid possible trouble with operation.

13) FASTENING OF FITTINGS TO LEAF Fig. L

14) LOCKING SETTING Fig. M

15) COVER POSITIONING Fig. N

16) ELEASE COVER FASTENING Fig. O

17) MAIN PARTS OF AUTOMATED SYSTEM Fig. P

.7QFSNBOFOUNBHOFUNPUPS

1-PCFQVNQ

%$POUSPMWBMWFBTTFNCMZ

$$ZMJOEFSXJUIQJTUPO

&-JOFBS&ODPEFS

$PNQPOFOUTQSPWJEFEöUUJOHTBUUBDIFEUPQJMMBSBOEHBUFSFMFBTFLFZJOTUSVD-

tion manual.

18) TIPS FOR SPECIAL INSTALLATIONS

With the leaf fully open, create a recess to accommodate the operator.

Fig. R gives the minimum dimensions of the recess for the various LUX BT 2B -

LUX G BT 2B models.

If distance “b” is greater than the values given in the installation tables:

- create a recess in the pillar Fig.S

- move the leaf so that it is ush with the pillar Fig.T.

19) LEAF STOPS AT GROUND LEVEL

For the actuator to work properly, it is advisable to use stops “F” to stop the leaves

both when they are open and closed, as illustrated in Fig.U.

The leaf stops must prevent the actuator rod from reaching the end of its tra-

vel.

20) TOPPING UP OIL Fig. V.

An oil change is recommended every 5 years.

21) MANUAL OPENING (See USER GUIDE -FIG.1-).

Loading...

Loading...