Installation and User Guide

SyncEV Charger | EVT77G.202205.NH www.syncev.co.uk

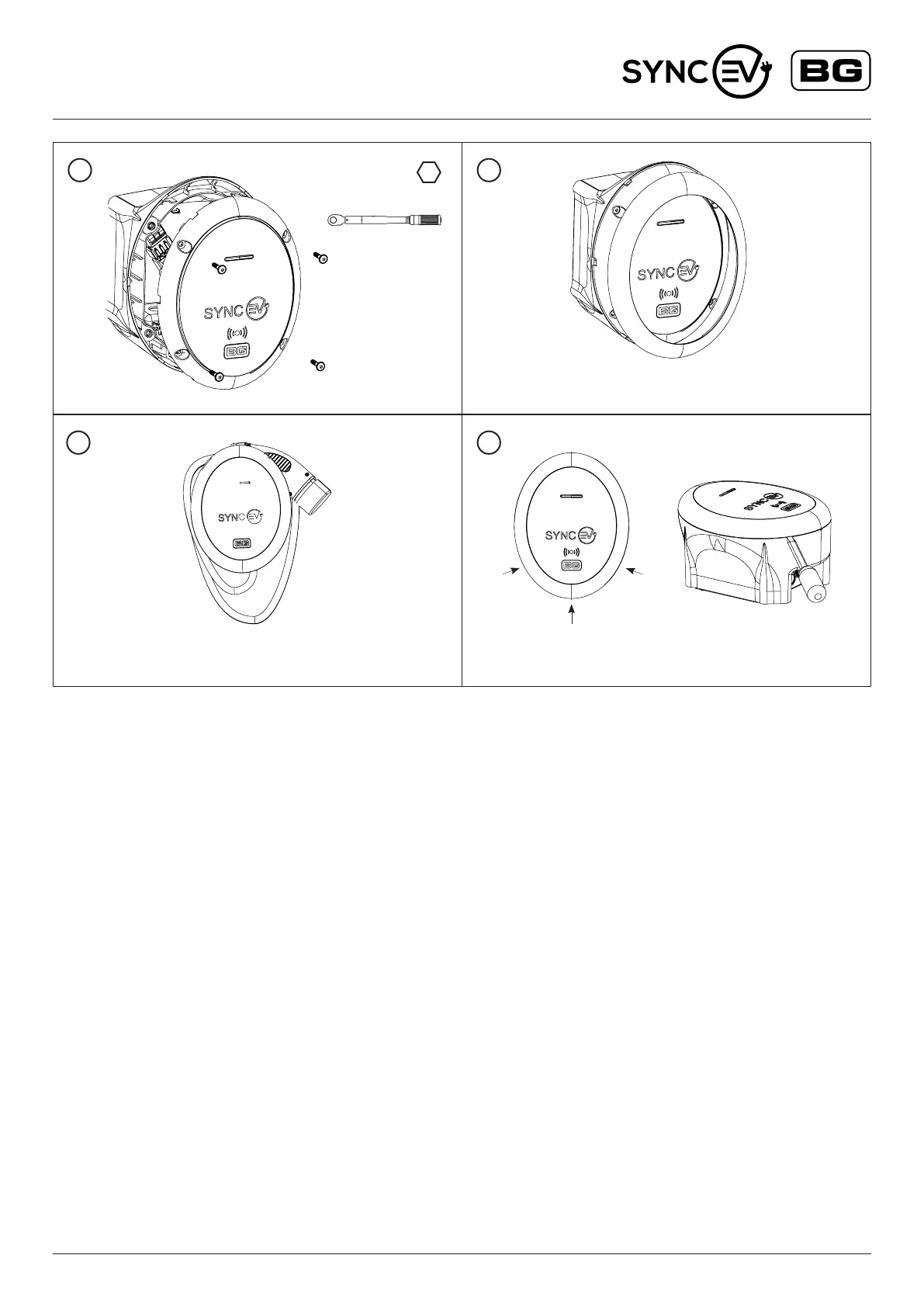

To remove trim, pry at shown points with a at toolWe recommend cable is wrapped securely around the charger,

with the gun placed at the top with its rubber cover tted

Snap front cover trim into place

4mm

2.5 N m

FINAL ELECTRICAL TESTING

To meet the BS7671:2018 (18th edition) requirements for testing

of an electrical installation, the following tests and checks shall be

performed by a competent electrical installer before during and after

a SyncEV BG charger is installed:

• A visual inspection of the installation including the existing

electrical installation.

• Verication of the characteristics of the electrical supply at

the origin of the installation to conrm the supply is suitable

for the additional load.

• A test to conrm the continuity of the circuit protective conductors.

• A test to conrm the integrity of the circuit insulation resistance.

• A test to conrm the polarity of the installation is correct.

• Where applicable a test to conrm the earth electrode

resistance is within acceptable tolerances.

(or)

• An earth loop impedance test.

• A test of the mechanical operation of residual current

devices (RCD’s).

• A test to conrm the operation of residual current devices (RCD’s)

is within stipulated time scales (at the rated current and at ve

times the rated current operating current).

• A test or calculated measurement of the prospective fault current.

• A verication of the functional operation of the EV charger.

Anelectricalinstallationcerticatemustbecompleted.

EnsureelectricaltestingisdonebeforeEVcharger

commissioningandnetworksetupisperformed.

9

1211

10

Loading...

Loading...