3

© ITW FINISHING SYSTEMS AND PRODUCTS

The following hazards may occur during the normal use of this equipment. Please

read the following chart before using the equipment.

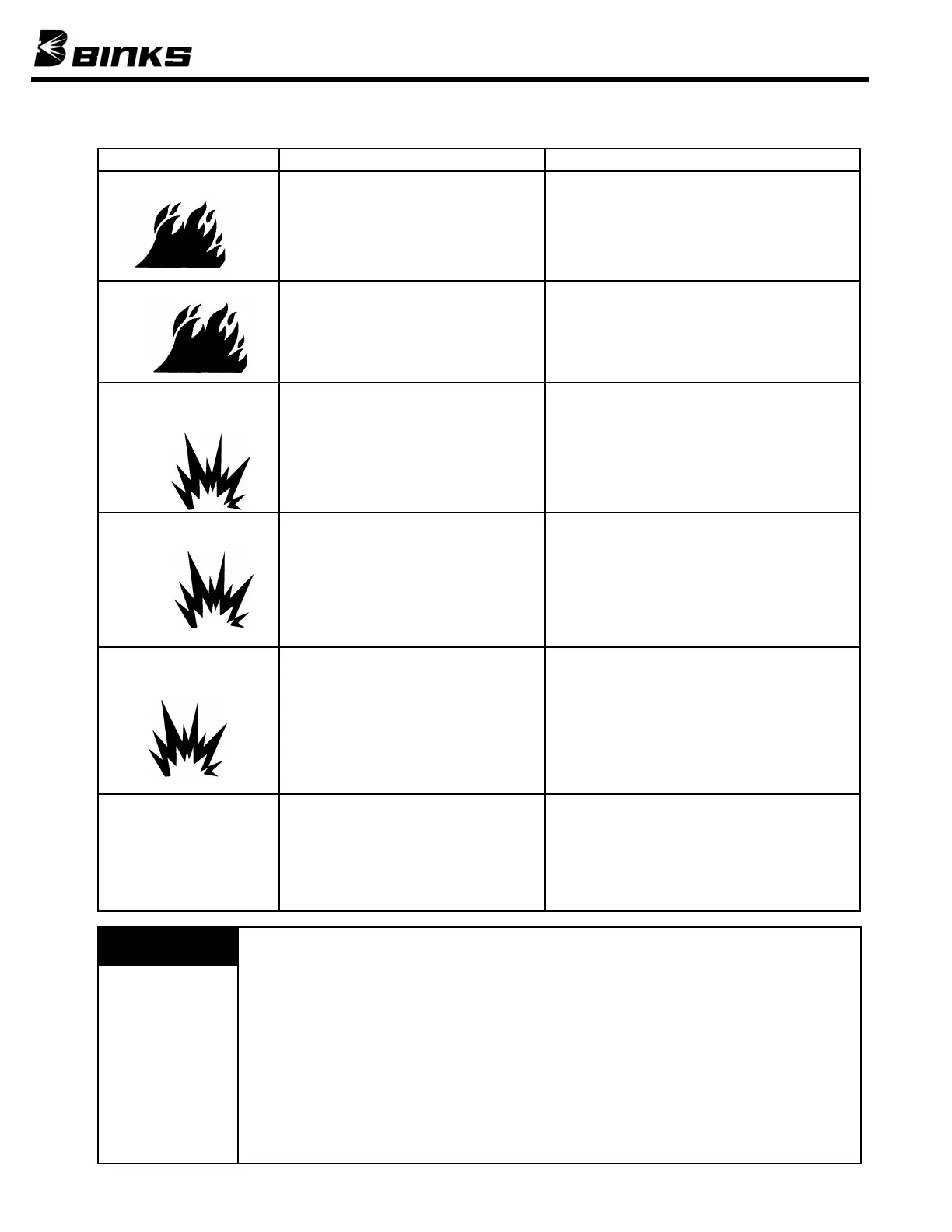

HAZARD CAUSE SAFEGUARDS

Fire

Solvents and coangs can be highly ammable

or combusble, especially when sprayed.

Adequate exhaust must be provided to keep the air free

of accumulaons of ammable vapours.

Smoking must never be allowed in the spray area.

Fire exnguishing equipment must be present in the spray

area.

Fire-

Pressure tank

Vapours from ammable liquids can catch re or

explode.

Keep tank at least 10 feet away from sources of ignion.

Ignion sources include hot objects, mechanical sparks,

and arcing (non -explosion proof) electrical equipment.

Explosion Hazard –

Pressure Tank –

Stac Electricity

Stac electricity is created by the ow of uid

through the pressure tank and hose. If all parts

are not properly grounded, sparking may occur.

Sparks can ignite vapours from solvents and the

uid being sprayed.

Ground the pressure tank by connecng one end of 12

gauge (minimum) ground wire to the pressure tank and

the other end to a true earth ground. Local codes may

have addional grounding requirements.

See illustraon g 3 on page 7 for grounding and

grounding hardware required.

Explosion Hazard –

Pressure Tank –

Rupture

Making changes to a pressure tank will weaken

it.

Never drill into, weld, or modify the tank in any way.

Do not adjust, remove, or tamper with the safety valve. If

replacement is necessary, use the same type and rang of

valve.

Explosion Hazard –

Galvanized Tanks –

Material Compability

Halogenated hydrocarbon solvents – for

example 1-1-1 Trichloroethane and methylene

chloride – can chemically react with aluminium

parts and components and cause an explosion

hazard. These solvents will also corrode the

galvanized tank coang.

Read the label or data sheet for the material. Do not use

materials containing these solvents with galvanized

pressure tanks. Stainless steel tank models may be used

with halogenated solvents.

Refer to specicaons chart to ensure that uids are

chemically compable with the tank weed parts. Before

placing uids or solvents in tank, always read

accompanying manufacturer’s literature.

General Safety Improper operaon or maintenance may create

a hazard.

Operators should be given adequate training in the safe

use and maintenance of this equipment. Refer to Pressure

Systems Safety Regulaons 2000 Approved Code of

Pracce (UK) or relevant naonal regulaons in the

country of use.

WARNING

PRESSURE RELIEF PROCEDURE

To reduce the risk of injury, follow the pressure relief procedure below

Before checking or servicing any part of the spray system

Before aempng removal of ll port cap or tank cover

Whenever the tank is le unaended

1. Turn o the main air supply to the tank.

2. Close the air inlet valve located on the tank air manifold.

3. Bleed o air in the tank by turning the air relief valve (5) thumb screw counter clockwise. Wait unl all the air has

escaped through the valve before removing the pressure tank cover or ll port cap.

4. Leave the air relief valve open unl you have reinstalled the tank cover or ll port cap.

High pressure can cause

serious injury.

Pressure is maintained in

a pressure tank aer the

system has been shut

down.

Always follow this

procedure to relieve

pressure from the tank.

Loading...

Loading...