© 2011 Blastpro Manufacturing Inc.

®

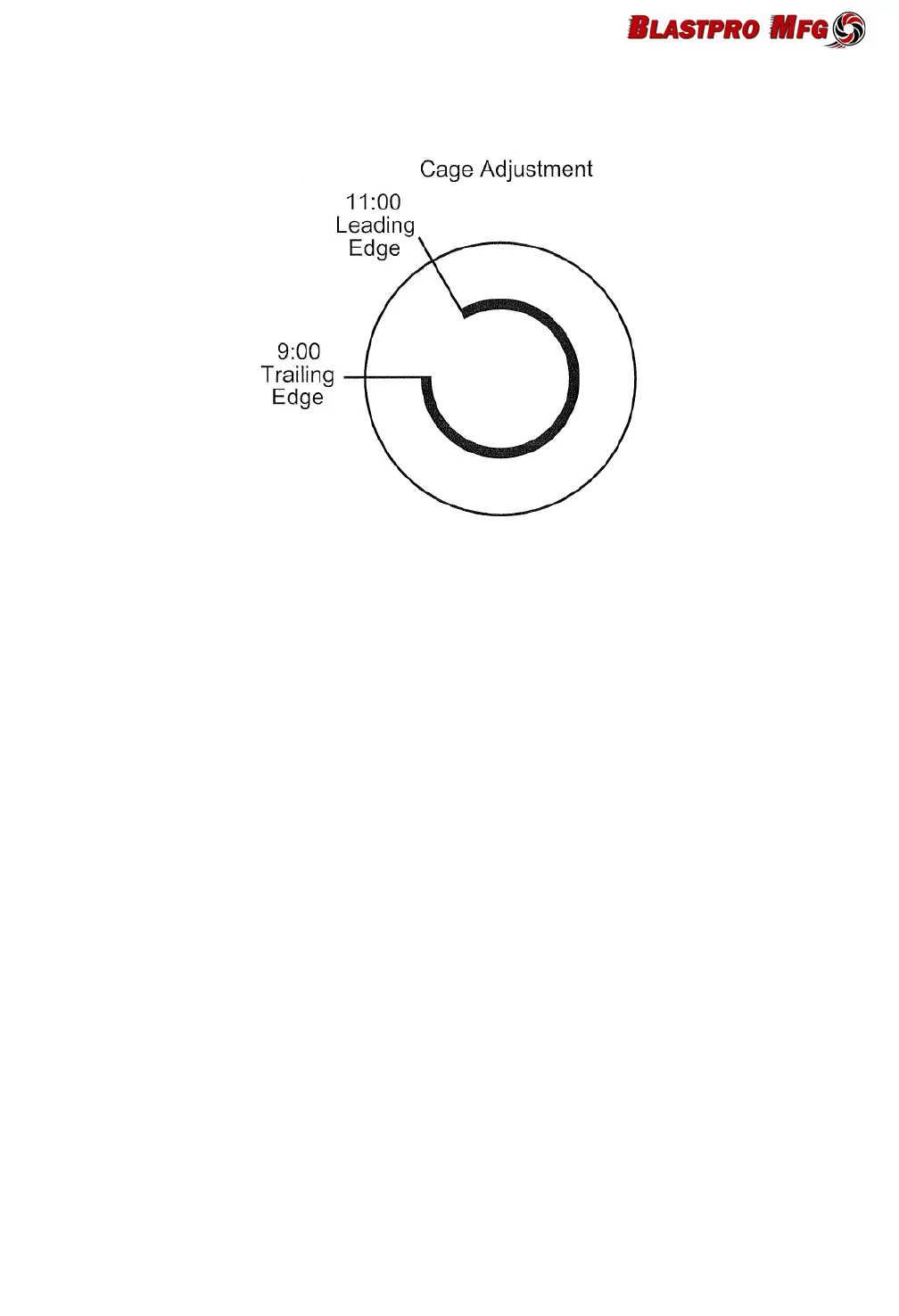

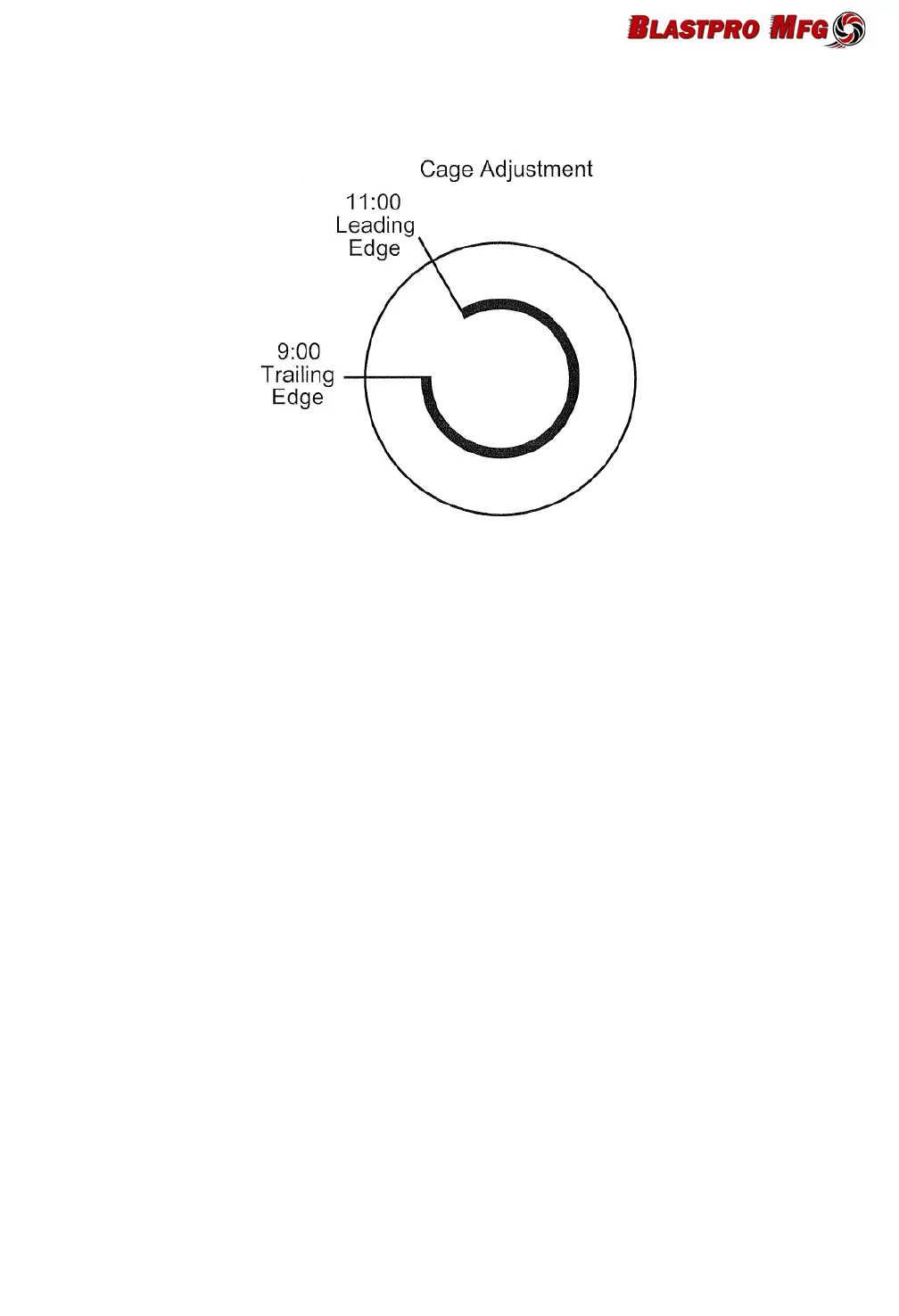

and, if necessary, replace the wheel rotation & the worn wheel kits. The proper control

cage setting is described in the following figure:

Shut Down:

1. Close the shot valve.

2. Stop the shot blasting machine forward & turn the speed control knob to zero.

3. Turn off the blast wheel.

4. Turn off the shot blasting machine.

5. Turn off the dust collector.

6. If this is only a temporary stoppage, then check the dust collector & empty it if

necessary. If this stoppage is the result of being done for the day, then empty the

dust collector no matter the amount of dust within it.

7. If this is only a temporary stoppage, then check the shot hopper & empty it if

necessary. If this stoppage is the result of being done for the day, then empty the

shot hopper no matter the amount of shot within it.

8. Make certain that the shot blasting machine is in a safe location if it is to be left at

the job site. If the shot blasting machine is to be transported, then please refer to

the section in this manual that addresses “Transportation.”

Transportation

When transporting the shot blasting machine, it is strongly recommended that personnel

act in a manner so as to reduce the potential that damage takes place as a result of using

excessive force or of using incorrect loading & unloading procedures. Personnel must

remove any shot from the machine before it is transported. Also, the machine may only

be lifted by using the suspension eyelets; forklifts should never to be used to transport

the shot blasting machine.

Loading...

Loading...