© 2011 Blastpro Manufacturing Inc.

®

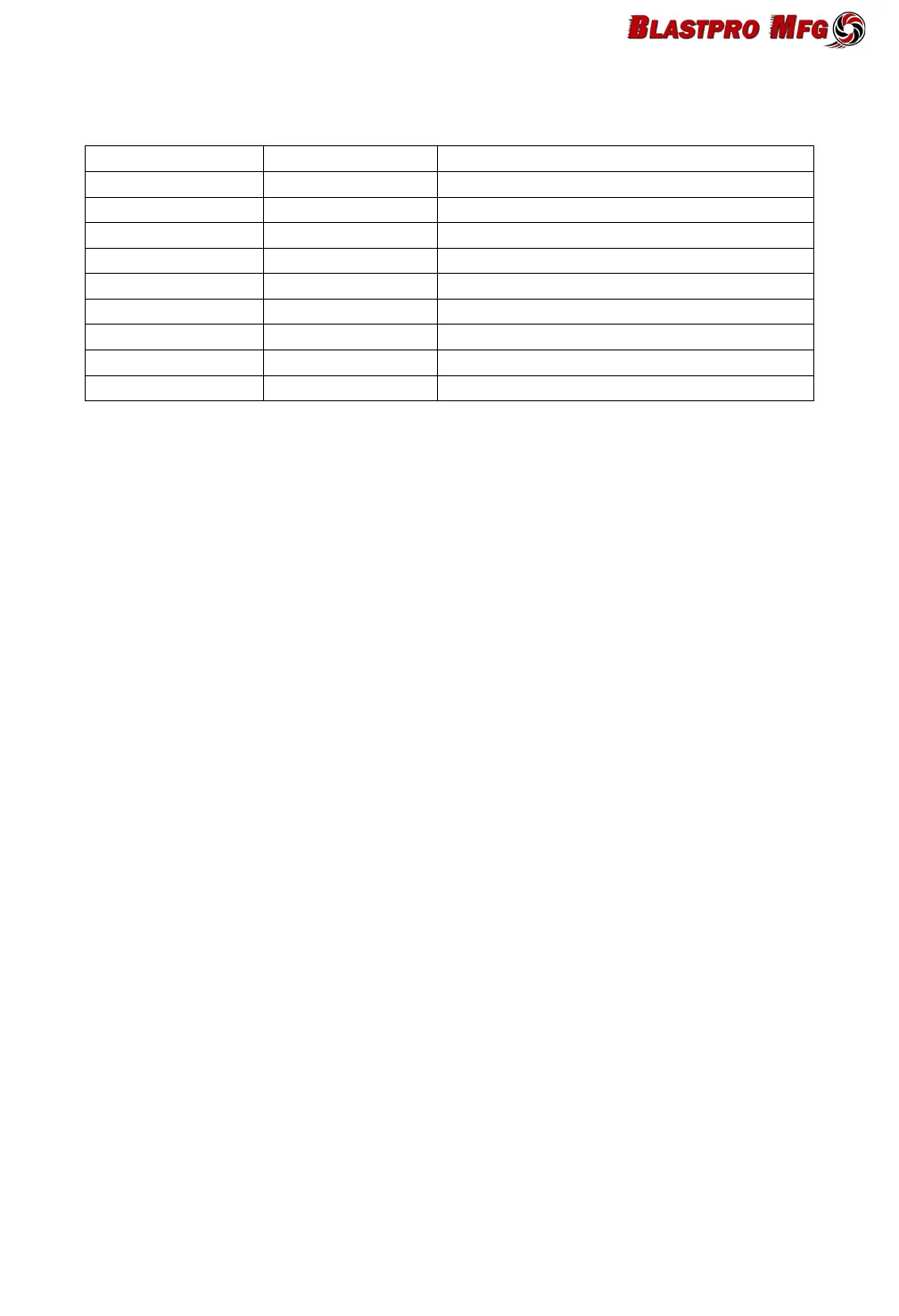

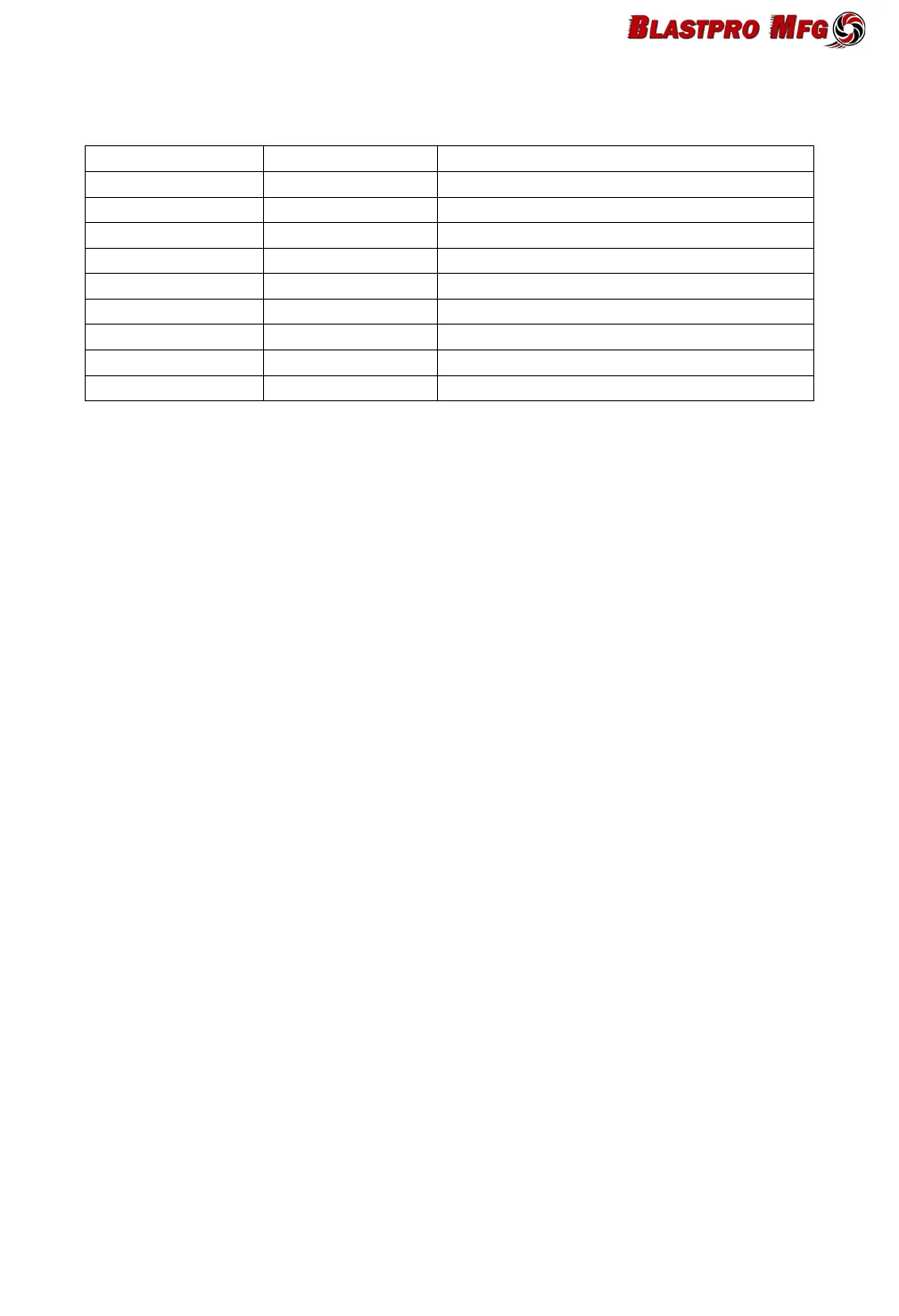

prior to operation & replace these parts when necessary. Wear parts & inspection times

on the machine, other than inspection prior to use, are listed below:

Blades deteriorated > 50%

Missing pins/deterioration

Warping, holes, deterioration

Thin sections or other deteriorations

Thin spots; wearing at welds

Thin spots; wearing at welds; warping

Parts of the machine which should also be inspected regularly but are not exposed to

steel shot are the control panel, motor, electric cords, dust collector hose, filters, & motors.

If any of these components show signs of wear, they should be repaired so that they are

in the same working condition as when they were new. If they cannot be repaired, then

they should be replaced immediately. Prior to any repair work, secure the machine

against unintentional switching-on. Put the machine in the safety off position. The

supplier’s operating & maintenance instructions should also be followed during service &

maintenance procedures.

Blast Wheel Removal & Installation

When the blades on the blast wheel are deteriorated by 50% or more, then the blast wheel

should be replaced. To replace the blast wheel, perform the following steps:

1. Verify that the shot blasting machine is turned off & disconnected from all power

sources.

2. Remove the feed spout & the control cage.

3. Remove the four mounting nuts, flat washers, & lock washers that secure the

control cage mounting assembly to the blast housing. Do not loosen any other

screws on the control cage mounting assembly since they are used to set the gap

between the blast wheel & the control cage. Remove the control cage mounting

assembly.

4. Remove the socket head cap screw & lock washers from the blast wheel & remove

the blast wheel.

5. Check the wheel hub for wear & replace if necessary.

6. Install new blast wheel using the new socket head cap screw & lock washers that

are included in the wheel kit. Be sure that the new blast wheel is seated properly

on the wheel hub before tightening the socket head cap screw.

7. Reinstall the control cage mounting assembly to the blast housing.

8. Install the new control cage that was included with the wheel kit. Rotate the wheel

by hand to be sure that the control cage & the wheel do no touch. The initial window

setting for the control cage should be between 8:30 & 10:30.

Loading...

Loading...