Operating Instructions for Suspended Jacks

17

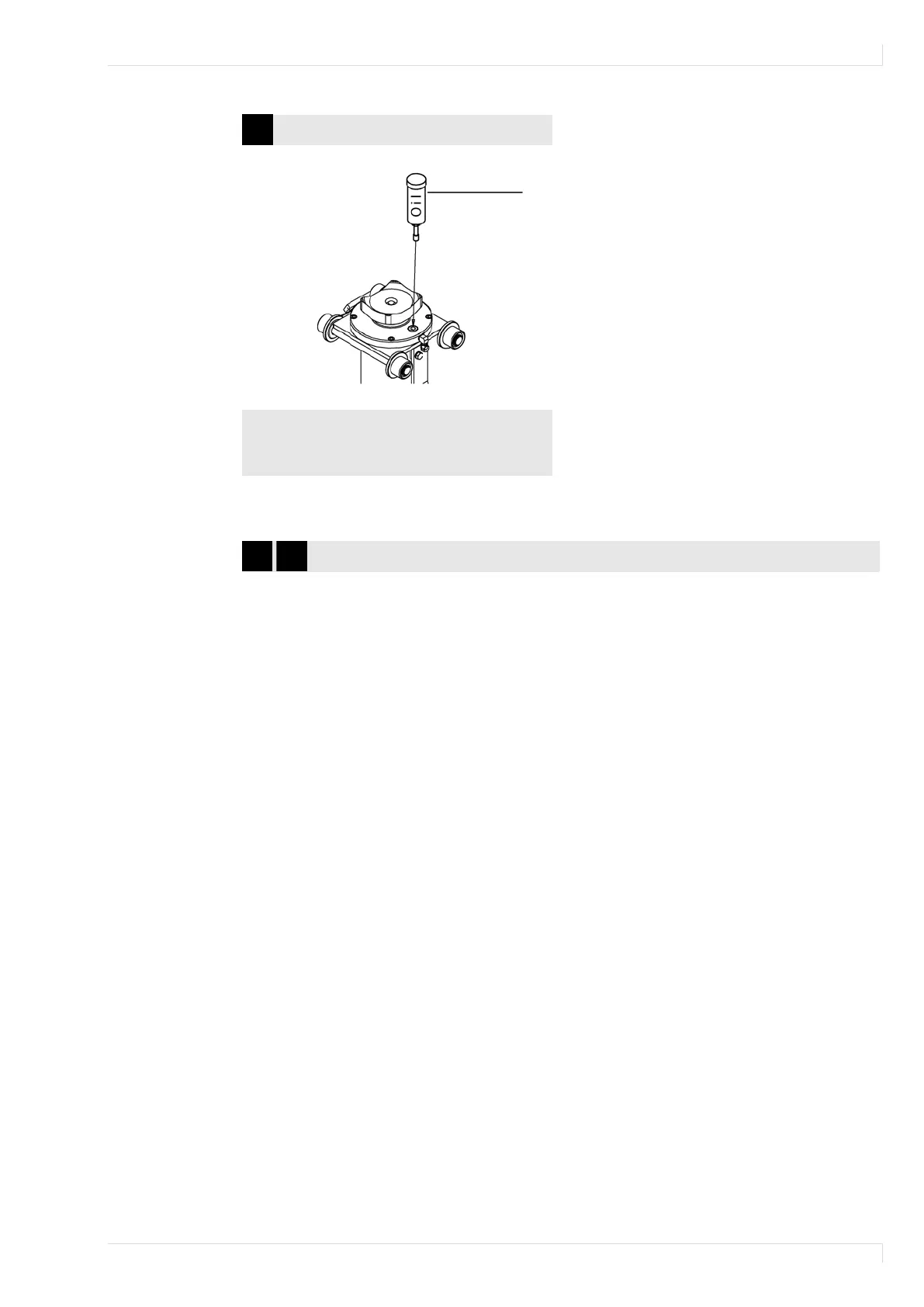

7.4 Top up Anti-Rust Oil

pump A and grease nipple.

7.5 Check the Hydraulic Oil Level

Hydraulic oil level load stroke

Retract piston rod [10] completely.

Unscrew the oil dip stick [7] and check the hydraulic oil level. Fill in new hydraulic oil up to the

mark. If oil level is too high, drain the condensate. ( 7.9)

Replace the dip stick.

Hydraulic oil level retrieval

Extend piston rod [10] completely.

Unscrew oil dip stick retrieval [9] and check hydraulic oil level.

Fill in new hydraulic oil up to the mark.

Replace the dip stick.

7.6 Perform Safety Test

The safety test must be performed by a specialist:

• Prior to initial commissioning

• Periodically after initial commissioning (at the latest yearly)

• After a change of the place of installation

• After repair work and changes in the construction

The following items must be checked on the lift:

• Quick reference guide

• Nameplate

• Marking on the lift

• Correct installation of the undercarriage

• Tilt protections on the lifting cylinder

• Pull-out safety devices at the undercarriage

• Condition of the load-carrying devices and the operating elements

• Condition of the support construction and the welding seams

• Leak-tightness of the hydraulic system

• Hydraulic oil level

• Connection cables/hoses

Perform function test

Enter the result into a test record.

Loading...

Loading...