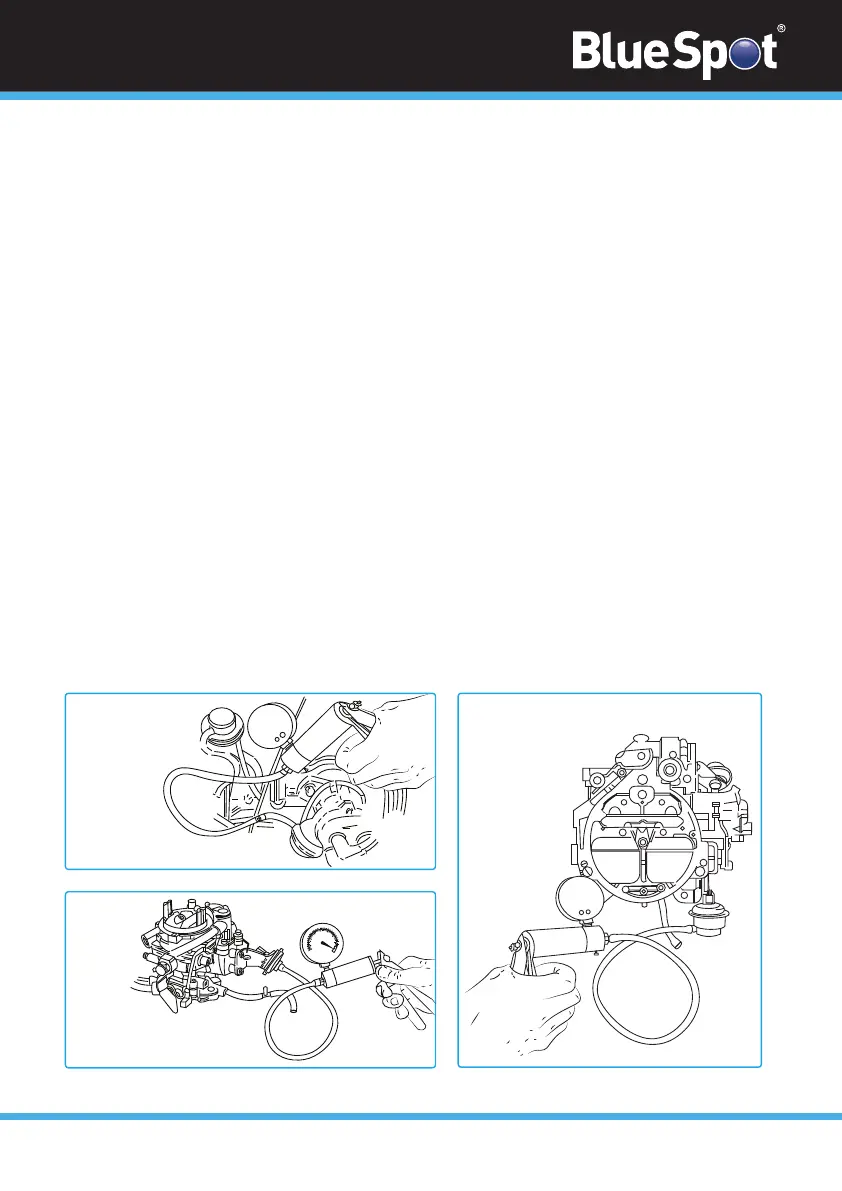

fig. 2

fig. 3

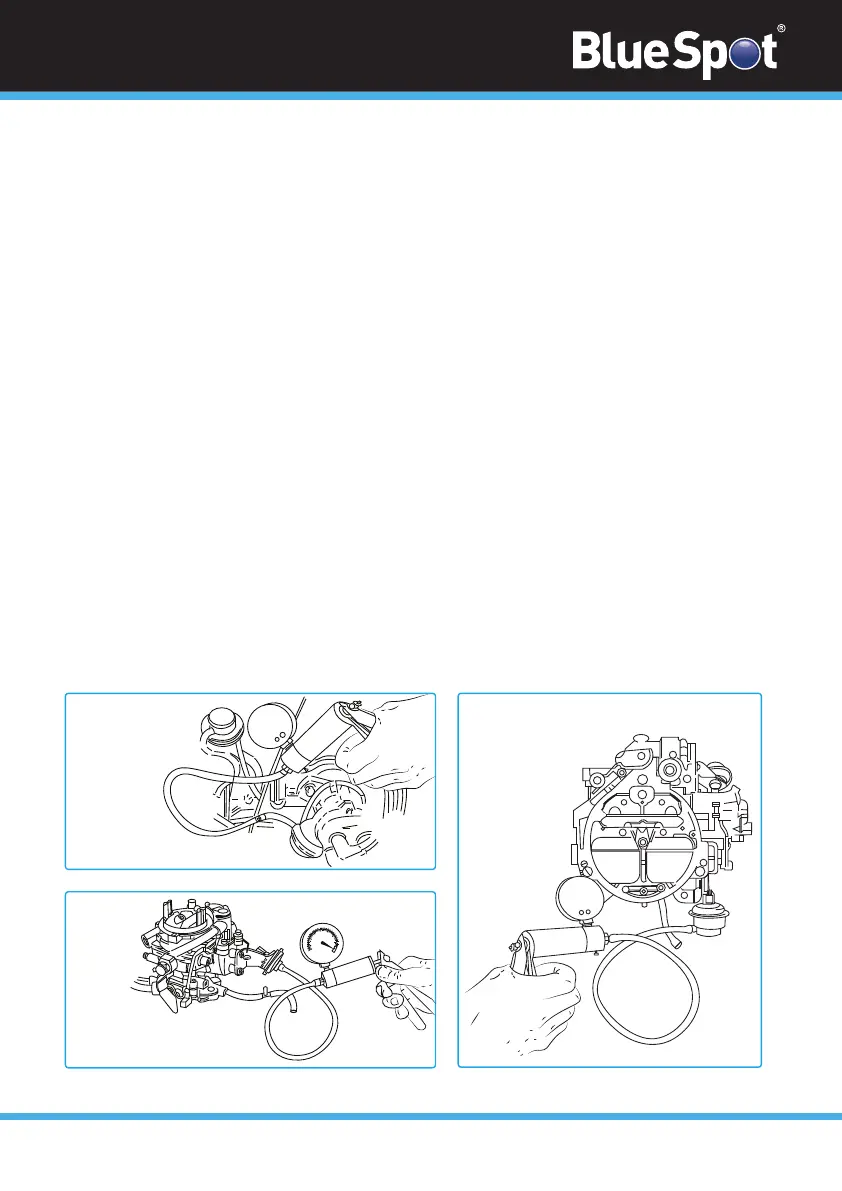

fig. 4

0

10

10

20

30

40

50

60

70

10

5

0

0

0

15

20

25

30

05

Ignition System Vacuum Advance

On standard points systems and some electronic ignition systems, there are two types of advanced

methods used, both of which function correctly to obtain maximum performance and fuel

economy. These are the mechanical or centrifugal method and the vacuum advance method.

Mechanical or Centrifugal Method

This method operates by the use of weights located in the base of the distributor. The weights

move outwards advancing ignition timing as engine RPM increases. Firstly remove the vacuum

advance line to disable the system. Then with the timing light connected, run the engine RPM up

checking that the timing advances in accordance with the manufacturer’s specification.

Vacuum Advance Method

This method senses engine load via the manifold vacuum. A vacuum diaphragm is mounted onto

the distributor and connected to a rotating internal base plate which advances or pulls back

timing as required to suit varying engine loads. For correct operation, again with the timing light

connected raise the engine RPM and check the timing advance against the manufacturer’s

specifications. If the vacuum advance is not operating, remove the vacuum line from the

distributor advance mechanism. Connect the vacuum tester (figure 2) and create a 5-10 inHg

vacuum, monitoring the timing at the same time. If a timing advance is noted this confirms that

the vacuum diaphragm and mechanical links are in order and that the fault is a vacuum supply. To

confirm this, connect the vacuum tester to the vacuum supply line and check the gauge reading.

No vacuum should be noted at idle but when the engine RPM is increased a vacuum increase

should be observed. If this does not occur, trace the vacuum line back checking for restrictions

and breaks.

Loading...

Loading...