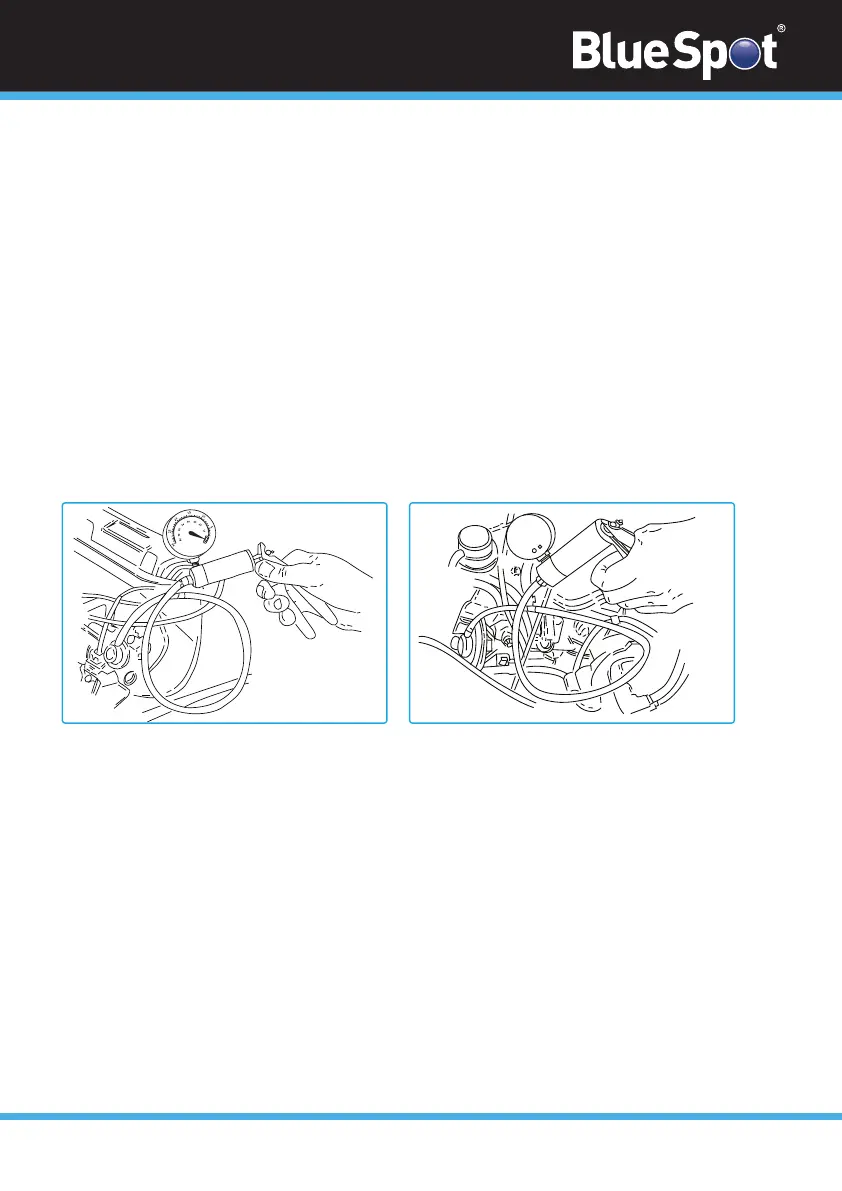

fig. 5

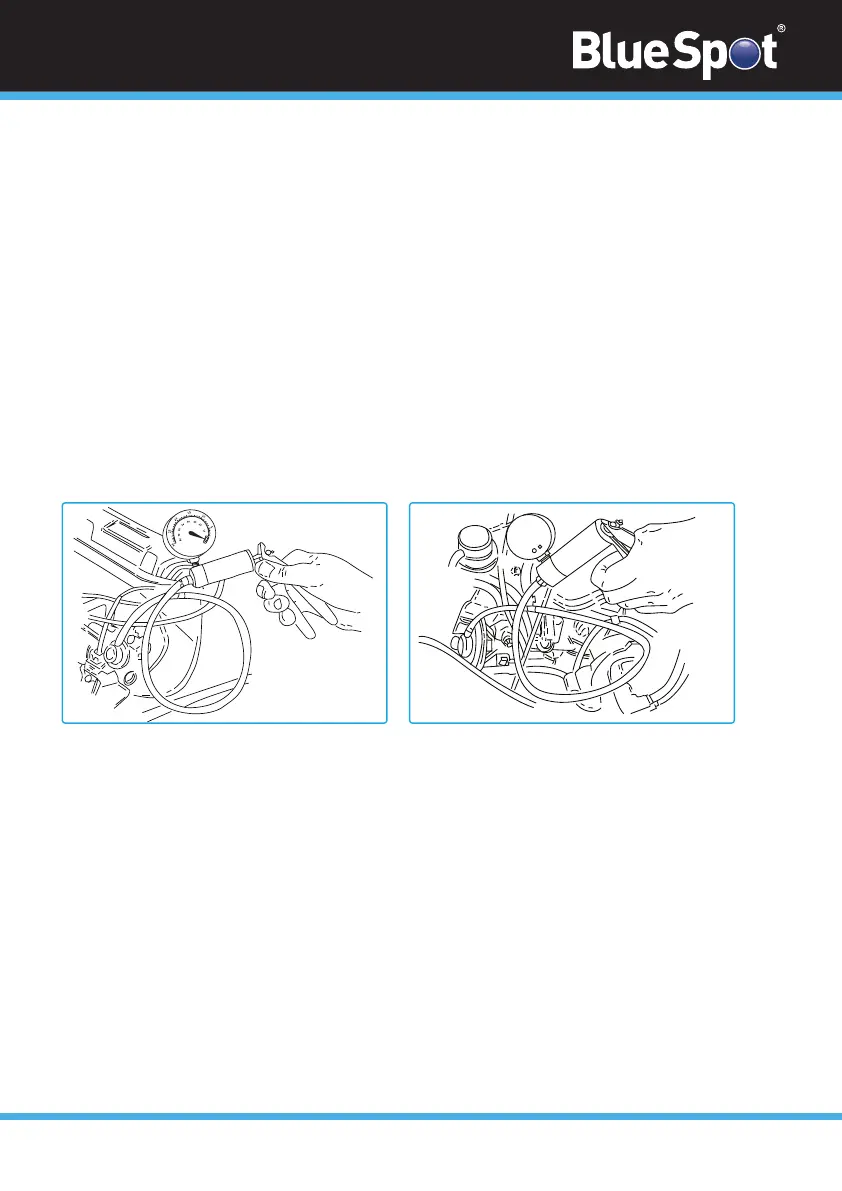

fig. 6

0

To test the fuel rail pressure

1. Attach a gauge to the rail.

2. The engine loads must then be created to vary engine manifold vacuum.

3. Remove and block off the vacuum supply line to the pressure regulator.

4. Connect and operate the vacuum pump (figure 5) to simulate vacuum pressures. Refer

to the manufacturer’s specifications. Note the variation in fuel pressure reading.

Testing Emission Control Exhaust Gas Recirculation Valves (EGR)

1. Start the engine. Run at idle until the normal operating temperature is reached.

2. Remove the vacuum line from the EGR valve and attach the vacuum tester kit

(figure 6).

3. Apply approximately 15inHG of vacuum by operating the hand pump.

The idle engine will become rough if the EGR valve is working correctly. If the idle engine

remains unchanged the valve is possibly seized in the closed position. If the vacuum is not

held, the diaphragm in the valve has failed.

Additional Vacuum Systems

Testing One-Way Valves

Many vacuum-operated circuits use in-line one-way valves to apply vacuum in one

direction only.

To test the function of the valve

1. Remove the valve from the circuit.

2. Attach the vacuum tester (figure 7) and apply vacuum by operating the pump.

3. In one direction the valve should hold vacuum and in the opposite direction, it

should not.

Testing Electrically Operated Vacuum Solenoids

Electrically operated vacuum solenoids are commonly used in control circuits for air

conditioning/ventilation systems, emission control systems, idle step up systems etc.

07

Loading...

Loading...