16 BA-100/1EN M52.XXXX

3.1 - Cruciform mounting plate assembly

3 - Assembly

3.1.1) Required parts

• Drill bits:

1 x ø5 mm clockwise (3.1) (marked in black)

1 x ø5 mm counterclockwise (3.2) (marked in red)

• Cover caps (2.3)

• Carcase side

• Cruciform mounting plate with system screws

3.1.2) Setting drill bit length (see point 2.1.2)

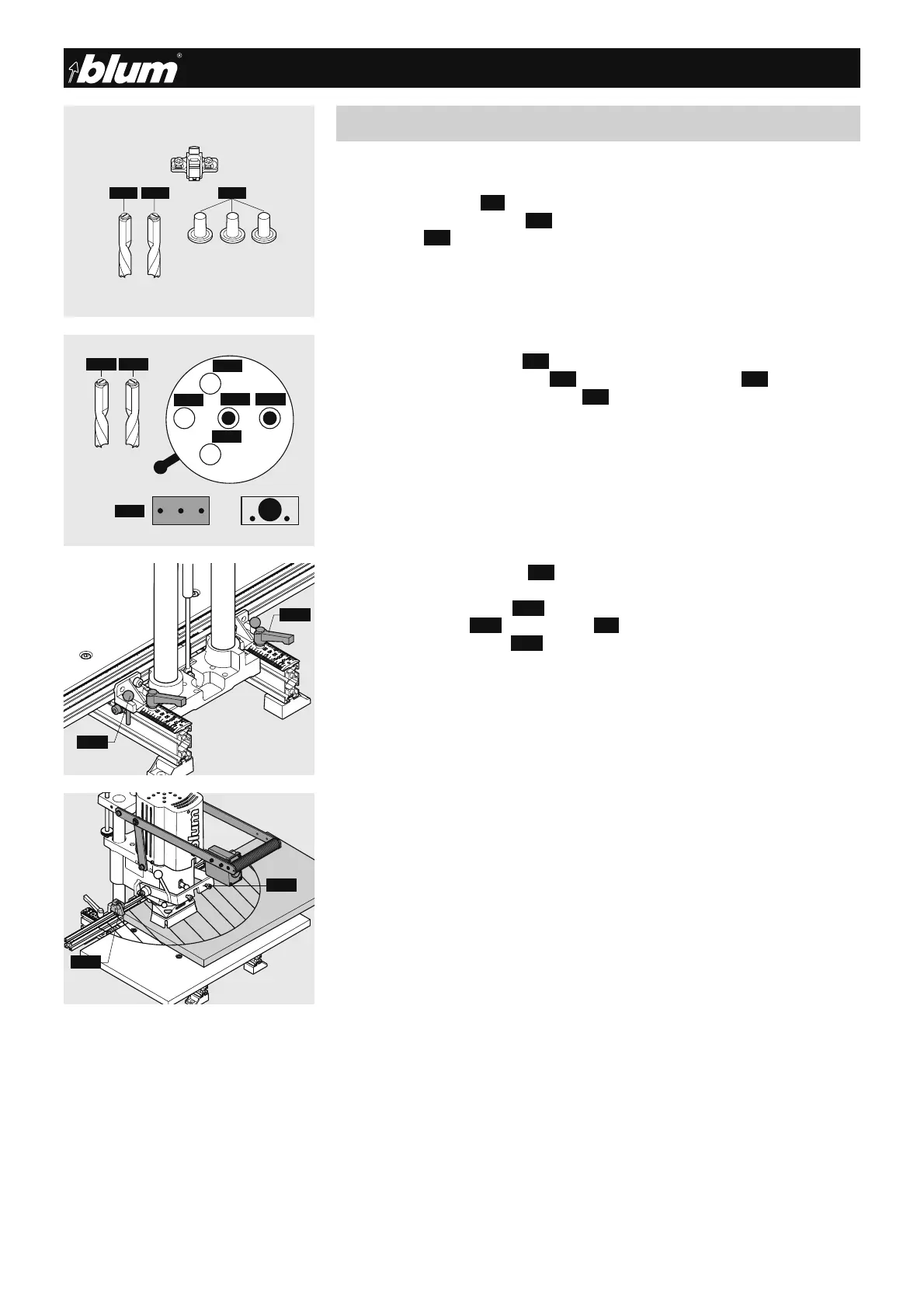

3.1.3) Setting drilling pattern

• Pull sprung loaded knob out (2.5) .

• At the same time, move the lever (2.6) to the “Hole group” symbol (3.3)

• Release knob back to original position (2.5) .

3.1.4) Installing drill bits into the chuck

(see point 2.1.4)

3.1.5) Checking drilling depth setting

(see points 2.1.5 / 2.1.6)

3.1.6) Setting the stop system(1.4)

• Loosen the clamping lever (2.15) .

• Remove locking pin(2.16) and set gauge (1.4) to SY.

• Secure the clamping lever (2.15) .

This fixed setting provides a drilling distance of 37 mm.

3.1.7) Placing carcase side on the work table and pushing up against the stop

(See point 2.1.9)

3.1.8) Drilling

(See point 2.1.12)

L

Loading...

Loading...