S250 Bobcat Loader

OI-34 Operation & Maintenance Manual

ATTACHMENTS AND BUCKETS (CONT’D)

Choosing The Correct Bucket (Cont’d)

Use the correct bucket size for the type and density of

material being handled. For safe handling of materials

and avoiding machine damage, the attachment

(or bucket) should handle a full load without going over

the Rated Operating Capacity for the loader. Partial loads

make steering more difficult.

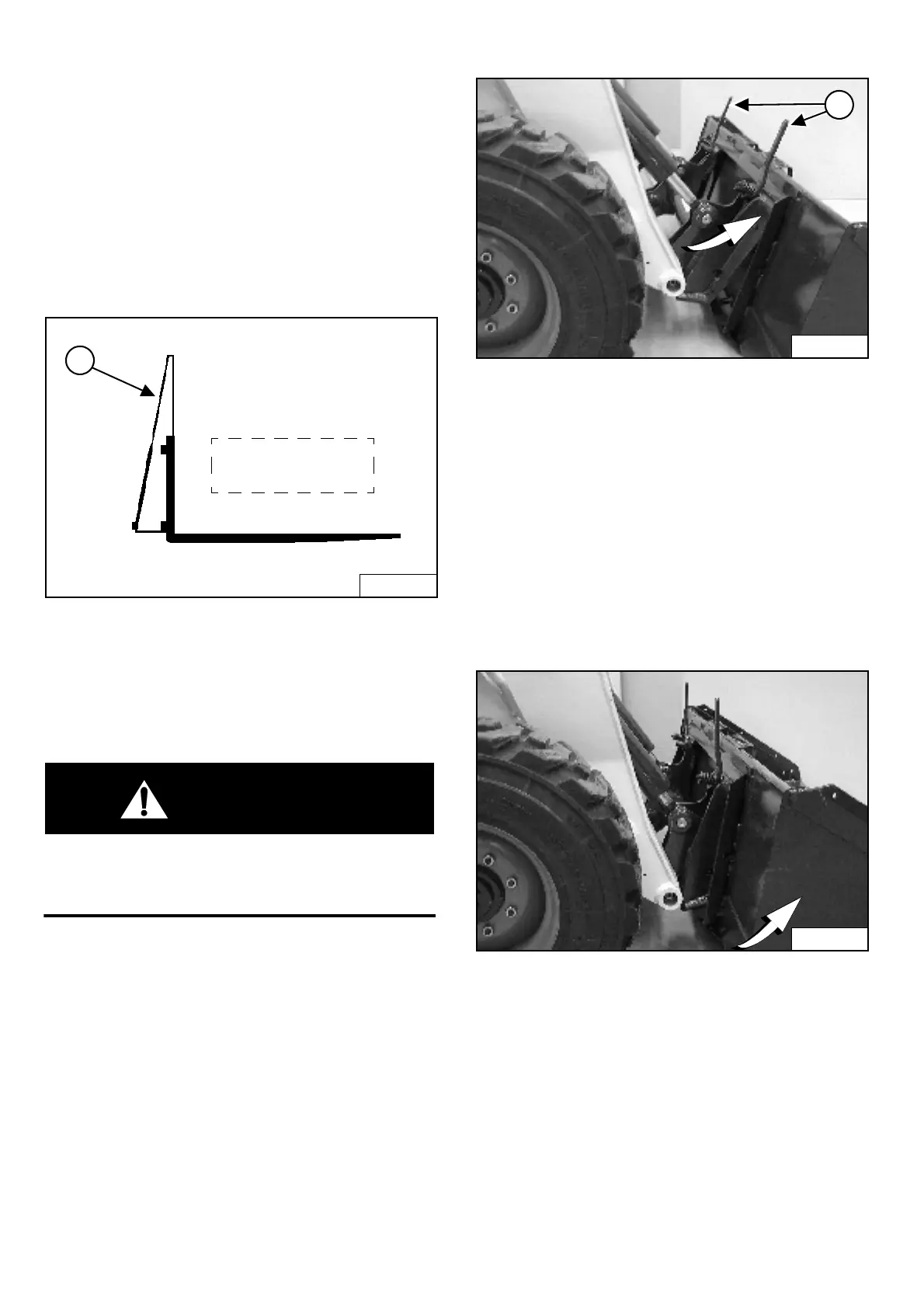

Pallet Forks

Figure OI-62

If a pallet fork attachment is used, the load center moves

forward and reduces the Rated Operating Capacity.

The maximum load to be carried when using a pallet fork

is shown on a decal located on the pallet fork

frame (Item 1) [Figure OI-62].

WARNING

AVOID INJURY OR DEATH

Do not exceed Rated Operating Capacity (ROC).

Excessive load can cause tipping or loss of control.

W-2053-0903

See your Bobcat Dealer for more information about pallet

fork inspection, maintenance and replacement. See your

Bobcat loader dealer for Rated Operating Capacity when

using a pallet fork and for other available attachments.

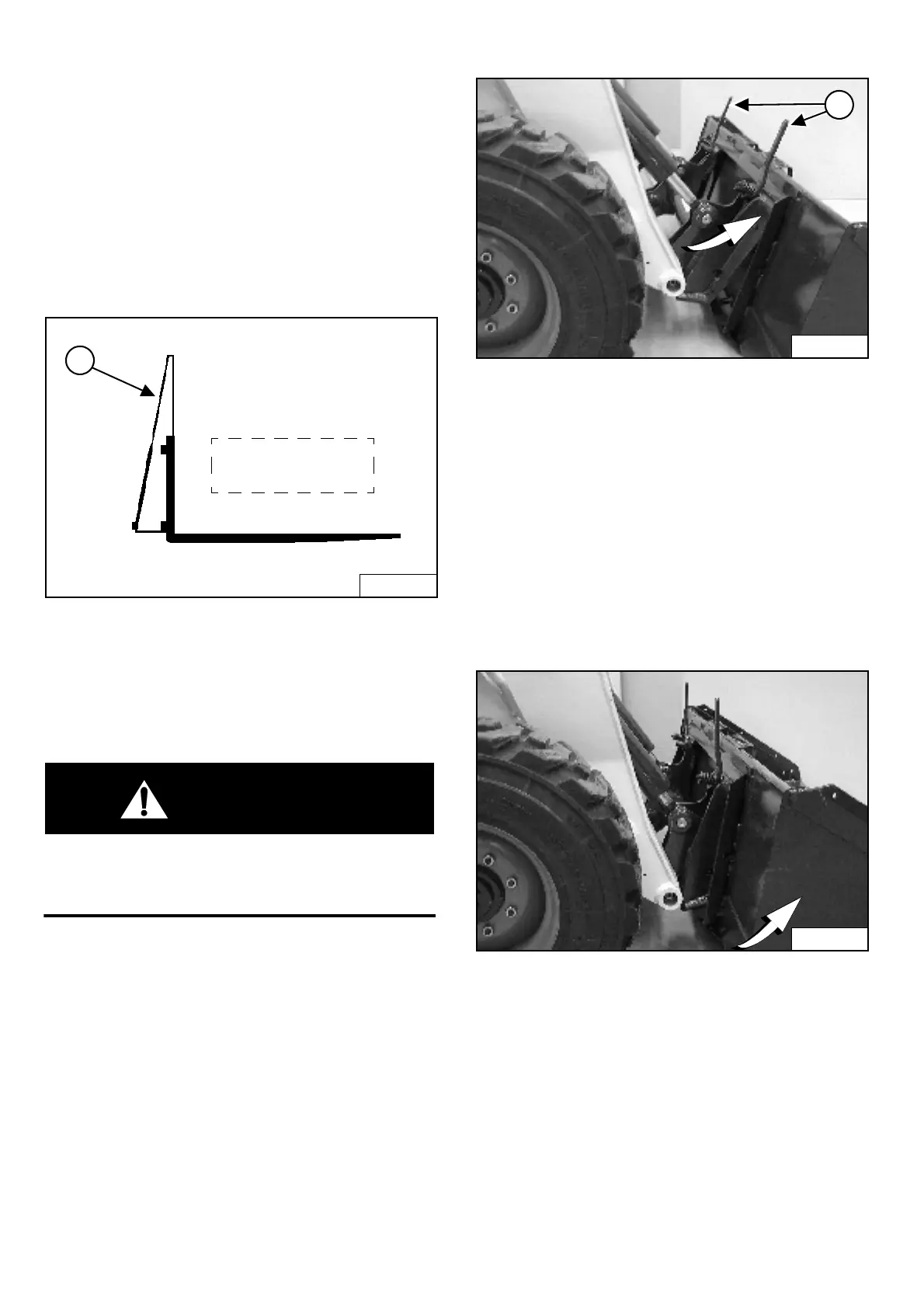

Hand Lever Bob-Tach - Installing The Bucket Or

Attachment

The Bob-Tach is used for fast changing of buckets and

attachments. See the appropriate Attachment Operation &

Maintenance Manual to install other attachments.

Figure OI-63

Pull the Bob-Tach levers all the way up (Item 1)

[Figure OI-63].

Enter the loader and perform the PRE-STARTING

PROCEDURE (See PRE-STARTING PROCEDURES on

Page OI-25).

Lower the lift arms and tilt the Bob-Tach forward.

Drive the loader forward until the top edge of the

Bob-Tach is completely under the top flange of the bucket

[Figure OI-63] (or other attachment). Be sure the

Bob-Tach levers do not hit the bucket.

Figure OI-64

Tilt the Bob-Tach backward until the cutting edge of the

bucket (or other attachment) is slightly off the ground

[Figure OI-64].

Stop the engine and exit the loader.

B-17255

1

Load varies with

model of pallet fork

being used.

P-31238

1

P-31239

Loading...

Loading...